Abstract

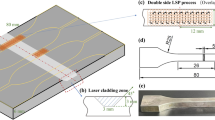

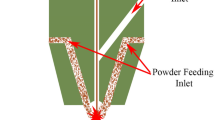

The paper shows the possibilities of using ultrasonic vibrations in the processes of laser welding and cladding. Optical and electron microscopy, local elemental analysis, X-ray tomography, and series of tensile tests were used to investigate the effect of vibrations on the respective processes. It is shown that ultrasonic vibrations can be used in two different ways: ultrasonic online processing during welding and surfacing and post processing of the finished weld seam and cladded metal. In the first case, ultrasonic effect leads to reduction of the weld seam thickness and an increase of the depth of weld penetration. In the second case, ultrasonic post-treatment of the samples produced by layer-by-layer direct laser wire deposition results in an increase of tensile strength of the cladded material up to 1.3 times. It is shown that the effect is caused by formation of an oriented thin-plate structures on the surface of the samples.

Similar content being viewed by others

References

Acherjee B (2018) Hybrid laser arc welding: State-of-art review. Opt Laser Technol 99(1):60–71

Steen WM, Eboo M, Clarke J (1978) Arc augmented laser welding. In: Proc. of the 4th International Conference on Advances in Welding Processes, 1978, 1, Harrogate, UK, pp 257–265

Ready JF (1997) Industrial applications of lasers, 2nd edn. Academic Press, London

Seyffarth P, Krivtsun IV (2002) Laser-arc processes and their applications in welding and material treatment. Taylor & Francis, London

Cui H, Decker I, Ruge J (1989) Wechselwirkungen zwischen WIG Schweißlichtbogen und fokussiertem Laserstrahl. In: Proc. of the Conference Laser’89, Springer, Berlin, pp 577–581

Magee KH, Merchant VE, Hyatt CV (1990) Laser assisted gas metal arc weld characteristics. In: Proc. of the Laser Materials Processing Conference ICALEO’90, Boston, USA, pp 382–389

Shi J, Zhu P, Fu G, Shi S (May 2018) Geometry characteristics modeling and process optimization in coaxial laser inside wire cladding. Opt Laser Technol 101:341–348

Wena P, Caia Z, Feng Z, Wanga G (2015) Microstructure and mechanical properties of hot wire laser clad layers for repairing precipitation hardening martensitic stainless steel. Opt Laser Technol 75:207–213

Mohammadpour M, Yazdian N, Wang H-P, Carlson B, Kovacevic R (January 2018) Effect of filler wire composition on performance of Al/galvanized steel joints by twin spot laser welding-brazing method. J Manuf Process 31:20–34

Kumar S, Wu CS, Padhy GK, Ding W (2017) Application of ultrasound vibrations in welding and metal processing: a status review. J Manuf Process 26:295–322

Chen YJ, Yue TM, Guo ZN (2018) Fatigue behaviour of titanium/PET joints formed by ultrasound-aided laser welding. J Manuf Process 31:356–363

Chen YJ, Yue TM, Guo ZN (2017) Laser joining of metals to plastics with ultrasound vibration. J Mater Process Technol 249:441–451

Gureev DM (1999) Prospects for laser-ultrasound treatment for surface modification, welding modification, welding, and pattern cutting. J Russ Laser Res 20(I)

Cong W, Ning F (2017) A fundamental investigation on ultrasound vibration assisted laser engineered net shaping of stainless steel. Int J Mach Tools Manuf 121:61–69

Hung JC, Tsai YP, Hung C (2013) Development of a new apparatus for ultrasound vibration-assisted glass hot embossing process. Precis Eng 37(1):222–227

Tsai YP, Hung JC, Yin LC, Hung C (2012) Ultrasound vibration-assisted optical glass hot embossing process. Int J Adv Manuf Technol 60(9–12):1207–1213

Mousavi SA, Feizi H, Madoliat R (2007) Investigations on the effects of ultrasound vibrations in the extrusion process. J Mater Process Technol 187:657–661

Laugier P, Haïat G (2011) Introduction to the physics of ultrasound. In: Bone quantitative ultrasound. Springer, Dordrecht, pp 29–45

Babitsky VI, Kalashnikov AN (2003) Ultrasoundally assisted turning of aviation materials. J Mater Process Technol 132(1):3157–3167

Shen XH, Zhang J, Xing D, Zhao Y (2012) A study of surface roughness variation in ultrasound vibration-assisted milling. Int J Adv Manuf Technol 58(5):533–561

Liao YS, Chen YC, Lin HM (2007) Feasibility study of the ultrasound vibration assisted drilling of Inconel superalloy. Int J Mach Tools Manuf 47(12):1988–1996

Qin N, Pei ZJ, Treadwell C, Guo DM (2009) Physics-based predictive cutting force model in ultrasound-vibration-assisted grinding for titanium drilling. J Manuf Sci Eng 131(4):111–119

Zheng HY, Huang H (2007) Ultrasound vibration-assisted femtosecond laser machining of microholes. J Micromech Microeng 17(8):58–61

Alavi SH, Harimkar SP (2015) Melt expulsion during ultrasound vibrationassisted laser surface processing of austenitic stainless steel. Ultrasounds 59:21–30

Abdullah A, Shabgard MR, Ivanov A, Shervanyi-Tabar MT (2009) Effect of ultrasound-assisted EDM on the surface integrity of cemented tungsten carbide (WC-Co). Int J Adv Manuf Technol 41(3–4):268–280

Ning F, Cong W (2016) Microstructures and mechanical properties of Fe-Cr stainless steel parts fabricated by ultrasonic vibration-assisted laser engineered net shaping process. Mater Lett 179:61–64

Zhou S, Ma G, Dongjiang W, Chai D, Lei M (2018) Ultrasonic vibration assisted laser welding of nickel-based alloy and austenite stainless steel. J Manuf Process 31:759–767

Ma G, Yan S, Wu D, Miao Q, Liu M, Niu F (2017) Microstructure evolution and mechanical properties of ultrasonic assisted laser clad yttria stabilized zirconia coating. Ceram Int 43(13):9622–9629

Li M, Han B, Wang Y, Song L, Guo L (2016) Investigation on laser cladding high-hardness nano-ceramic coating assisted by ultrasonic vibration processing. Optik - Int J Light Electron Opt 127(11):4596–4600

Patent RU 2618287 Gilmutdinov A.Kh., Gorunov A.I. A method for laser product treatment (variants) and device for its implementation (variants), Application submission date: 04.08.2015, Published in bulletin No. 13, 05.03.2017

Patent RU 165178 Gilmutdinov A.Kh., Gorunov A.I. Device for casting of products from metals from metals and alloys, Application submission date: 04.07.2015, Published in bulletin No. 28: 10.10.2016

Acknowledgments

The authors are grateful to the Ministry of Education of the Russian Federation for supported research projects the State assignment 9.3236.2017/4.6 and Federal target program No. 14.z50.31.0023 resolution of the RF Government 220 and No. 14.578.21.0245.

The authors would like to thank our students: E. Popov, A. Gaisina, S. Nikiforov, and A. Mukhametov for taking part in this research and contribution to the results obtained.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gorunov, A.I., Nyukhlaev, O.A. & Gilmutdinov, A.K. Investigation of microstructure and properties of low-carbon steel during ultrasonic-assisted laser welding and cladding. Int J Adv Manuf Technol 99, 2467–2479 (2018). https://doi.org/10.1007/s00170-018-2620-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2620-7