Abstract

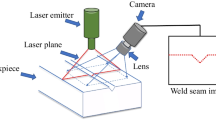

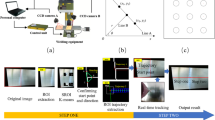

In recent years, passive vision-based methods in the weld seam tracking system are becoming more and more popular due to their higher accuracy and robustness to various interferences. In this paper, we present a novel robust weld seam tracking system based on passive vision. A robust discriminative correlation filter is proposed to locate the seam accurately by using weld seam images and background images as positive and negative samples,respectively. Additionally, a new online updating filter strategy is proposed to reduce the effect of varying illumination or changing structure and appearance. The two-scale searching window mode and the fast Fourier transform are combined to increase the speed and precision of the weld seam tracking. The extensive experimental results indicate that the proposed method is simple and fast, and also, its accuracy is high in tracking weld seams. The proposed system has been applied successfully to industrial production lines.

Similar content being viewed by others

References

Bae KY, Park JH (2005) A study on development of inductive sensor for automatic weld seam tracking. J Mater Process Technol 176(1):111–116

Mahajan A, Figueroa F (1997) Intelligent seam tracking using ultrasonic sensors for robotic welding. Robotica 15:275–281

Kim J, Shin JH (2003) A study on a dual-electromagnetic sensor system for weld seam tracking of i-butt joints. Proc Inst Mech Eng Part B J Eng Manuf 217(9):1305–1313

Kawahara M (1983) Tracking control system using image sensor for arc welding. Automatica 19(4):357–363

Lee SK, Na SJ (2002) A study on automatic seam tracking in pulsed laser edge welding by using a vision sensor without an auxiliary light source. J Manuf Syst 21(4):302–315

Chen SB, Zhang Y, Qiu T, Lin T (2003) Robotic welding systems with vision-sensing and self-learning neuron control of arc welding dynamic process. J Intell Robot Syst 36(2):191–208

Muhammad J, Altun H, Abo-Serie E (2016) Welding seam profiling techniques based on active vision sensing for intelligent robotic welding. Int J Adv Manuf Technol 88(1-4):127–145

Gao X, Ding D, Bai T, Katayama S (2009) Weld pool image centroid algorithm for seam tracking in arc welding process. In: 2009 IEEE International Workshop on Imaging Systems and Techniques, IEEE Computer Society, Washington, D.C., pp 385–390

Baskoro AS, Rui M, Kabutomori M, Suga Y (2009) An application of genetic algorithm for edge detection of molten pool in fixed pipe welding. Int J Adv Manuf Technol 45(11-12):1104–1112

Guo B, Shi Y, Yu G, Wang K (2016) Weld deviation detection based on wide dynamic range vision sensor in mag welding process. Int J Adv Manuf Technol 87(9-12):3397–3410

Shen HY, Wu J, Lin T, Chen SB (2008) Arc welding robot system with seam tracking and weld pool control based on passive vision. Int J Adv Manuf Technol 39(7–8):669–678

Xu Y, Fang G, Chen S, Zou JJ, Ye Z (2014) Real-time image processing for vision-based weld seam tracking in robotic GMAW. Int J Adv Manuf Technol 73(9–12):1413–1425

Dinham M, Fang G (2014) Detection of fillet weld joints using an adaptive line growing algorithm for robotic arc welding. Robot Comput Integr Manuf 30(3):229–243

Chen X, Chen S, Lin T, Lei Y (2006) Practical method to locate the initial weld position using visual technology. Int J Adv Manuf Technol 30(7-8):663–668

Zou Y, Wang S, Dong D, Chang B (2009) Method of weld recognition based on textural feature matching. China Welding 18(4):21–25

Nele L, Sarno E, Keshari A (2013) An image acquisition system for real-time seam tracking. Int J Adv Manuf Technol 69(9-12):2099–2110

Wang X, Shi Y, Yu G, Li Y (2016) Groove-center detection in gas metal arc welding using a template-matching method. Int J Adv Manuf Technol 86(9):2791–2801

George CS, Linda GS (2001) In Computer Vision, 1st edn. Prentice Hall PTR, Upper Saddle River, pp 41–46

Bolme DS, Beveridge JR, Draper BA, Lui YM (2010) Visual object tracking using adaptive correlation filters. In: Proceedings of the 2010 IEEE Conference on Computer Vision and Pattern Recognition, IEEE Computer Society, Washington, D.C., pp 2544–2550

Forsyth D (2010) Object detection with discriminatively trained part-based models. IEEE Trans Pattern Anal Mach Intell 32(9):1627–1645

Rui C, Martins P, Batista J (2012) Exploiting the circulant structure of tracking-by-detection with kernels. In: Proceedings of the 12th European Conference on Computer Vision - Volume Part IV. Springer, Berlin, pp 702–715

Danelljan M, Khan FS, Felsberg M, Weijer J (2014) Adaptive color attributes for real-time visual tracking. In: Proceedings of the 2014 IEEE conference on computer vision and pattern recognition, IEEE Computer Society, Washington, D.C., pp 1090–1097

Henriques JF, Caseiro R, Martins P, Batista J (2015) High-speed tracking with kernelized correlation filters. IEEE Trans Pattern Anal Mach Intell 37(3):583–596

Danelljan M, Häger G, Khan FS (2014) Accurate scale estimation for robust visual tracking. In: Valstar M, French A, Pridmore T (eds) Proceedings of the British Machine Vision Conference. BMVA Press, Dundee, pp 65.1-65.11

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Li, B. & Zhang, T. Robust discriminant correlation filter-based weld seam tracking system. Int J Adv Manuf Technol 98, 3029–3039 (2018). https://doi.org/10.1007/s00170-018-2254-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2254-9