Abstract

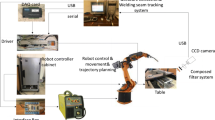

Gas metal arc welding (GMAW) process is one of the most widespread welding processes used in industries for their excellent quality, reliability, productivity, and cost-effectiveness. To develop an automatic GMAW system, vision capability in the system is a necessary component supplying real-time information about weld pool and seam tracking. In this research work, an automatic seam tracking system is presented, where the automatic tracking of welding path and torch positioning are performed by a newly developed image acquisition system. The system aims to add a vision capability to the GMAW system. A CCD camera is configured with a welding torch to acquire real-time images. The acquired images are processed through newly developed software for real-time detection of welding seam location and characteristics. The software encapsulates the acquired image input facility, image filtering technique, strategy to measure the seam gap, strategy to position torch at the starting point of welding, user interface for automatic guide, and the strategy to correct the torch movements. The seam recognition accuracy was verified during several welding experiments on linear weld seam. Real-time measurements of the seam gap and the seam tracking have achieved a high accuracy.

Similar content being viewed by others

References

Schreiber D, Cambrini L, Biber J, Sardy B (2008) Online visual quality inspection for weld seams. Int J Adv Manuf Technol 42(5–6):497–504

Xu P, Xu G, Tang X, Yao S (2007) A visual seam tracking system for robotic arc welding. Int J Adv Manuf Technol 37(1–2):70–75

Ge J, Zhu Z, He D, Chen L (2005) A vision-based algorithm for seam detection in a PAW process for large-diameter stainless steel pipes. Int J Adv Manuf Technol 26:1006–1011

Je-Yong Y, Suck-Joo N (1998) A study on vision sensors for seam tracking of height-varying weldment. Part 2: applications. Mechatronics 8(1):21–36

Chen Xi-Zhang, Huang Yu-Ming, Chen Shan-ben (2012) Model analysis and experimental technique on computing accuracy of seam spatial position information based on stereo vision for welding robot. Ind Robot Int J 39(4):349–356

Chen SB, Chen XZ, Li JQ (2005) The research on acquisition of welding seam space position information for arc welding robot based on vision. J Intell Robot Syst 43:77–97

Gini M (1987) The future of robot programming. Robotica 5:235246

Mcfarland WD, Mclaren RW (1983) Problems in three-dimensional image. In: Proceeding of the 3rd international conference on robot vision and sensory control, p 31139

Bauchspiessa A, Alfarob SCA, Dobrzanski LA (2001) Predictive sensor guided robotic manipulators in automated welding cells. J Mater Process Technol 109:13–19

Agapiou G, Kasiouras C, Serafetinides AA (1999) A detailed analysis of the MIG spectrum for the development of laser-based seam tracking sensors. Opt Laser Tech 31:157–161

Wikle HC, Zee RH, Chin BA (1999) A sensing system for weld process control. J Mater Process Technol 89–90:254–259

Kuo HC, Wu LJ (2002) An image tracking system for welded seams using fuzzy logic. J Mater Process Technol 120:169–185

Bae KY, Lee TH, Ahn KC (2002) An optical sensing system for seam tracking and weld pool control in gas metal arc welding in steel pipe. J Mater Process Technol 120:458–465

Kim P, Rhee S, Lee CH (1999) Automatic teaching of welding robot for free-formed seam using laser vision sensor. Opt Lasers Eng 31:173–182

Jeng JY, Mau TF, Leu SM (2000) Gap inspection and alignment using a vision technique for laser butt joint welding. Int J Adv Manuf Technol 16:212–216

Keshari A, Daddona D, Teti R, Minutolo CF (2011) Projection based image processing for automatic tool wear detection, X AITEM Conference, 12-14 sept, Naples, Italy, pp 89–90. ISBN 978-88-906061-0-1

Daddon D, Teti R (2010) Monitoring of cutting tool wear through images analysis, 6th virtual conference on intelligent production, machines and systems—IPROMS2010, 15–26 Nov

He Y, Makeev A, Shonkwiler B (2012) Characterization of nonlinear shear properties for composite materials using digital image correlation and finite element analysis. Compos Sci Technol 73:64–71

Chen X, Chen S, Lin T, Lei Y (2006) Practical method to locate the initial position of weld seam using visual technology. Int J Adv Manuf Technol 30:663–668

Chen XZ, Chen SB (2010) The autonomous detection and guiding of start welding position for arc welding robot. Ind Robot 37(1):70–78

Kong M, Shi FH, Chen SB, Lin T (2007) Recognition of the initial position of weld based on the corner detection for welding robot in global environment. Springer, Berlin, pp 249–255

Wei S, Wang J, Chen S (2012) Application of image morphology in detecting and extracting the initial welding position. J Shanghai Jiaotong Univ 17(3):323–326

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nele, L., Sarno, E. & Keshari, A. An image acquisition system for real-time seam tracking. Int J Adv Manuf Technol 69, 2099–2110 (2013). https://doi.org/10.1007/s00170-013-5167-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5167-7