Abstract

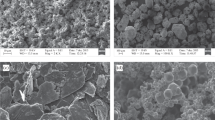

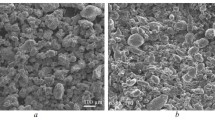

The sintering of Fe-Cu and Fe-Cu-Ni3Al powder compacts by laser beam was studied to determine densification, microstructural development, and microhardness before and after thermo-mechanical treatments. Laser sintering (LS) was conducted using pulsed Nd:YAG laser, and optimum parameters of pulse energy, pulse length, pulse frequency, scanning speed, hatch spacing, and layer thickness were determined. Also, the effects of solidification rate, cold deformation (10%), and the addition of complex intermetallic Ni3Al (Fe, Ti, B) on microhardness were analyzed before and after the aging process. It was concluded that rapidly solidified structure, as well as the presence of Ni3Al particles and metastable CuFe phase, which are a product of laser sintering, affected a higher degree of iron matrix hardening which was retained up to high temperatures. Originality of investigations presented in this paper is in the employment of laser for synthesis of Fe-Cu-Ni3Al alloy, which was not discussed in the literature so far. Realization of this complex synthesis required consideration and adaptation of the laser sintering method which has been successfully applied for other types of alloys.

Similar content being viewed by others

References

Lawley A (1992) Atomization: the production of metal powders. MPIF, Princeton

Bloom TA (1989) Rapid solidification of high-conductivity copper alloys. Dissertation, Illinois Institute of Technology

McHugh KM, Lin Y, Zhou Y, Lavernia EJ (2008) Influence of cooling rate on phase formation in spray-formed H13 tool steel. Mater Sci Eng A 477:50–57

Bachmaier A, Kerber M, Setman D, Pippan R (2012) The formation of supersaturated solid solutions in Fe-Cu alloys deformed by high-pressure torsion. Acta Mater 60:860–871

Jia Q, Gu D (2014) Selective laser melting additive manufacturing of Inconel 718 superalloy parts: densification, microstructure and properties. J Alloy Compd 585:713–721

Kurz W, Trivedi R (1994) Rapid solidification processing and microstructure formation. Mater Sci Eng A 179-180, Part 1:46–51

Louvis E, Fox P, Sutcliffe CJ (2011) Selective laser melting of aluminium components. J Mater Process Technol 211:275–284

Sercombe T, Jones N, Day R, Kop A (2008) Heat treatment of Ti-6Al-7Nb components produced by selective laser melting. Rapid Prototyp J 14:300–304

Kruth JP, Froyen L, van Vaerenbergh J, Mercelis P (2004) Selective laser melting of iron-based powder. J Mater Process Technol 149:616–622

Yang J, Ouyang H, Xu C, Wang Y (2012) Top surface quality research for direct metal laser fabrication. Rapid Prototyp J 18:4–15

Takaki S, Fujioka M, Aihara S, Nagataki Y, Yamashita T, Sano N, Adachi Y, Nomura M, Yaguchi H (2004) Effect of copper on tensile properties and grain-refinement of steel and its relation to precipitation behavior. Mater Trans 45:2239–2244

Deschamps A, Militzer M, Poole WJ (2001) Precipitation kinetics and strengthening of a Fe-0.8wt%Cu alloy. ISIJ Inter 41:196–205

Jiandong H, Yulong L, Zhang L (1993) Microstructure and properties of a Fe-C-Cu-MoS2 alloy prepared by laser sintering. J Mater Sci 28:2664–2668

Shen P, Hu J, Guo Z, Guan Q (1999) A study on laser sintering of Fe-Cu powder compacts. Metall Mater Trans A 30A:2229–2235

Boivie K (2000) SLS application of the Fe-Cu-C system for liquid phase sintering. In: Bourell DL et al (eds) Proceedings of the solid freeform fabrication symposium 2000. The University of Texas at Austin, pp 141–149

Stoloff N (1989) Physical and mechanical metallurgy of Ni3Al and its alloys. Int Met Rev 34:153–183

Gessinger GH (1984) Powder metallurgy of superalloys. Butterworth and Co, London

Van der Schueren B, Kruth JP (1994) Laser based selective metal powder sintering, a feasibility study. Proc 26th Int. CIRP Sem on Manufacturing, pp 793–802

Morgan R, Papworth A, Sutcliffe C, Fox P, O’Neill B (2001) Direct metal laser re-melting of 316L RVS powder. Part 2: analysis of cubic primitives. In: Proc. solid freeform fabrication symposium 2001. The University of Texas at Austin, pp 283–295

Niebling F, Otto A, Geiger M (2004) Temperature and stress development in the DMLS process. In: Geiger M, Otto A (eds) Proc. 4th international conference on laser assisted net shape engineering LANE 2004. Meisenbach, pp 465–472

Harrison NJ, Todd I, Mumtaz K (2015) Reduction of micro-cracking in nickel superalloys processed by selective laser melting: a fundamental alloy design approach. Acta Mater 94:59–68

Malukhin K, Ehmann K (2006) Manufacturing of shape memory alloy based monolithic functional structures with shape memory effect properties. Transactions North Am Manuf Res Inst SME 34:261–268

Malukhin K, Ehmann K (2007) Identification of direct metal deposition (DMD) process parameters for manufacturing thin wall structures from shape memory alloy (NiTi) powder. Trans North Am Manuf Res Inst SME 35:481–488

Božić D, Mitkov M, Ilić N, Jovanović MT, Zdujić M (1994) Microstructure and mechanical properties of hot-pressed Ni3Al based intermetallic powder produced by rotating electrode process. Mater Lett 21:161–166

Kwon SC, Cho HD, Kim WW, Moon WJ, Kim YM, Kim YJ (2006) Radiation hardening mechanism of Fe-Cu. In: Transactions of the Korean Nuclear Society Spring Meeting, Chuncheon, Korea, May 25–26, 2006

Ren HP, Wang HJ, Liu ZC, An ZG (2007) Nanometer stripe microstructure of supersaturated solid solution in Fe-Cu alloy. J Iron Steel Res Int 14:64–68

Bacon DJ, Osetsky YN (2009) Mechanisms of hardening due to copper precipitates in α-iron. Phil Mag 89:2–27

Maury F, Lorenzelli N, Mathon MH, de Novion CH, Lagarde P (1994) Copper precipitation in FeCu, FeCuMn, and FeCuNi dilute alloys followed by X-ray absorption spectroscopy. J Phys Condens Matter 6:569–588

Pizzini S, Roberts KJ, Phythian WJ, English CA, Greaves GN (1990) A fluorescence EXAFS study of the structure of copper-rich precipitates in Fe-Cu and Fe-Cu-Ni alloys. Phil Mag Lett 61:223–229

Goodman SR, Brenner SS, Low JR (1973) An FIM-atom probe study of the precipitation of copper from iron-1.4 at. pct copper. Part II: atom probe analyses. Metall Trans 4:2363–2369

Osamura K, Okuda H, Ochiai S, Takashima M, Asano K, Furusaka M, Kishida K, Kurosawa F (1994) Precipitation hardening in Fe-Cu binary and quaternary alloys. ISIJ Inter 34:359–365

Russell KC, Brown LM (1972) A dispersion strengthening model based on differing elastic moduli applied to the iron-copper system. Acta Metall 20:969–974

Worrall GM, Buswell JT, English CA, Hetherington MG, Smith GDW (1987) A study of the precipitation of copper particles in a ferrite matrix. J Nucl Mater 148:107–114

Othen PJ, Jenkins ML, Smith GDW, Pythian WJ (1991) Transmission electron microscope investigations of the structure of copper precipitates in thermally-aged Fe-Cu and Fe-Cu-Ni. Phil Mag Lett 64:383–391

Rees DWA (1998) Deformation and fracture of metal matrix particulate composites under combined loadings. Comp Part A 29A:171–182

Funding

The results presented are realized with the financial support of the Ministry of Education, Science and Technological Development of the Republic of Serbia through project no. 172005.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Božić, D., Stanković, N., Ružić, J. et al. Synthesis and multiple hardening of a rapidly solidified iron-based matrix. Int J Adv Manuf Technol 96, 4009–4019 (2018). https://doi.org/10.1007/s00170-018-1839-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1839-7