Abstract

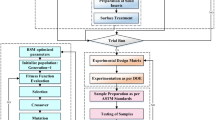

This research aims to evaluate Al-Al joints fabricated by overcasting liquid 2024 Al alloy onto Zn-electroplated 2024 Al alloy solid inserts followed by solidification under pressure. The effects of three most influencing process parameters including squeeze pressure, die temperature and melt temperature on the mechanical properties of as-casted and aged overcast joints were investigated. Response surface methodology with central composite design was employed for experimental design and development of empirical models. The observed responses in this research include ultimate tensile strength and hardness. Adequacy and validity of the developed models were verified through ANOVA and confirmation experiments, respectively. For both as-casted and aged overcasting conditions, the results revealed melt temperature as the most significant process parameter affecting ultimate tensile strength and hardness followed by die temperature and squeeze pressure. The comparative analysis of the two conditions suggested aged overcasting as the better alternative which resulted in 5.7~9.8 and 3.6~12.4% improvement in ultimate tensile strength and hardness, respectively.

Similar content being viewed by others

References

Williams JC, Starke EA (2003) Progress in structural materials for aerospace systems. Acta Mater 51(19):5775–5799. https://doi.org/10.1016/j.actamat.2003.08.023

Taub AI, Krajewski PE, Luo AA, Owens JN (2007) The evolution of technology for materials processing over the last 50 years: the automotive example. JOM J Miner Met Mater Soc 59(2):48–57. https://doi.org/10.1007/s11837-007-0022-7

Liu T, Wang Q, Sui Y, Wang Q (2016) Microstructure and mechanical properties of overcast 6101–6101 wrought al alloy joint by squeeze casting. J Mater Sci Technol 32(4):298–304. https://doi.org/10.1016/j.jmst.2015.11.020

Chang S et al (2009) Joining 6061 aluminum alloy with al–Si–cu filler metals. J Alloys Compd 488(1):174–180. https://doi.org/10.1016/j.jallcom.2009.08.056

Lee K et al (2013) Influence of reduction ratio on the interface microstructure and mechanical properties of roll-bonded Al/Cu sheets. Mater Sci Eng A 583:177–181. https://doi.org/10.1016/j.msea.2013.06.077

Xue P, Ni DR, Wang D, Xiao BL, Ma ZY (2011) Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Mater Sci Eng A 528(13):4683–4689. https://doi.org/10.1016/j.msea.2011.02.067

Chang C et al (2010) Effect of laser welding on properties of dissimilar joint of Al-Mg-Si and Al-Mn aluminum alloys. J Mater Sci Technol 26(3):276–282. https://doi.org/10.1016/S1005-0302(10)60046-1

Honarpisheh M, Asemabadi M, Sedighi M (2012) Investigation of annealing treatment on the interfacial properties of explosive-welded Al/Cu/Al multilayer. Mater Des 37:122–127. https://doi.org/10.1016/j.matdes.2011.12.045

Akatsu T, Hosoda N, Suga T, Rühle M (1999) Atomic structure of Al/Al interface formed by surface activated bonding. J Mater Sci 34(17):4133–4139. https://doi.org/10.1023/A:1004661610307

Lee T et al (2013) Controlling Al/Cu composite diffusion layer during hydrostatic extrusion by using colloidal Ag. J Mater Process Technol 213(3):487–494. https://doi.org/10.1016/j.jmatprotec.2012.10.001

Yu Z, Duan Y, Liu L, Liu S, Liu X, Li X (2009) Growth behavior of Cu/Al intermetallic compounds in hot-dip aluminized copper. Surf Interface Anal 41(5):361–365. https://doi.org/10.1002/sia.3020

Liu T, Wang Q, Sui Y, Wang Q, Ding W (2016) An investigation into interface formation and mechanical properties of aluminum–copper bimetal by squeeze casting. Mater Des 89:1137–1146. https://doi.org/10.1016/j.matdes.2015.10.072

Sun J, Song X, Wang T, Yu Y, Sun M, Cao Z, Li T (2012) The microstructure and property of Al–Si alloy and Al–Mn alloy bimetal prepared by continuous casting. Mater Lett 67(1):21–23. https://doi.org/10.1016/j.matlet.2011.08.112

Wang T, Liang C, Chen Z, Zheng Y, Kang H, Wang W (2014) Development of an 8090/3003 bimetal slab using a modified direct-chill casting process. J Mater Process Technol 214(9):1806–1811. https://doi.org/10.1016/j.jmatprotec.2014.03.029

Hajjari E, Divandari M, Razavi SH, Emami SM, Homma T, Kamado S (2011) Dissimilar joining of Al/Mg light metals by compound casting process. J Mater Sci 46(20):6491–6499. https://doi.org/10.1007/s10853-011-5595-4

Papis K et al (2008) Interface formation in aluminium–aluminium compound casting. Acta Mater 56(13):3036–3043. https://doi.org/10.1016/j.actamat.2008.02.042

Viala J et al (2002) Interface chemistry in aluminium alloy castings reinforced with iron base inserts. Compos A: Appl Sci Manuf 33(10):1417–1420. https://doi.org/10.1016/S1359-835X(02)00158-6

Liu H et al (2006) Interfacial strength and structure of stainless steel–semi-solid aluminum alloy clad metal. Mater Lett 60(2):180–184. https://doi.org/10.1016/j.matlet.2005.08.015

Şimşir M, Kumruoğlu LC, Özer A (2009) An investigation into stainless-steel/structural-alloy-steel bimetal produced by shell mould casting. Mater Des 30(2):264–270. https://doi.org/10.1016/j.matdes.2008.04.074

Xu G, Luo AA, Chen Y, Sachdev AK (2014) Interfacial phenomena in magnesium/aluminum bi-metallic castings. Mater Sci Eng A 595:154–158. https://doi.org/10.1016/j.msea.2013.11.093

Paramsothy M, Srikanth N, Gupta M (2008) Solidification processed Mg/Al bimetal macrocomposite: microstructure and mechanical properties. J Alloys Compd 461(1):200–208. https://doi.org/10.1016/j.jallcom.2007.07.050

Xiong B, Cai C, Wan H, Lu B (2011) Fabrication of high chromium cast iron and medium carbon steel bimetal by liquid–solid casting in electromagnetic induction field. Mater Des 32(5):2978–2982. https://doi.org/10.1016/j.matdes.2011.01.006

Xiong B, Cai C, Lu B (2011) Effect of volume ratio of liquid to solid on the interfacial microstructure and mechanical properties of high chromium cast iron and medium carbon steel bimetal. J Alloys Compd 509(23):6700–6704. https://doi.org/10.1016/j.jallcom.2011.03.142

Hejazi MM, Divandari M, Taghaddos E (2009) Effect of copper insert on the microstructure of gray iron produced via lost foam casting. Mater Des 30(4):1085–1092. https://doi.org/10.1016/j.matdes.2008.06.032

Papis K, Löffler J, Uggowitzer P (2010) Interface formation between liquid and solid Mg alloys—An approach to continuously metallurgic joining of magnesium parts. Mater Sci Eng A 527(9):2274–2279. https://doi.org/10.1016/j.msea.2009.11.066

Zhang H, Chen Y, Luo AA (2014) A novel aluminum surface treatment for improved bonding in magnesium/aluminum bimetallic castings. Scr Mater 86:52–55. https://doi.org/10.1016/j.scriptamat.2014.05.007

Hajjari E, Divandari M (2008) An investigation on the microstructure and tensile properties of direct squeeze cast and gravity die cast 2024 wrought Al alloy. Mater Des 29(9):1685–1689. https://doi.org/10.1016/j.matdes.2008.04.012

Koerner C, Schwankl M, Himmler D (2014) Aluminum–aluminum compound castings by electroless deposited zinc layers. J Mater Process Technol 214(5):1094–1101. https://doi.org/10.1016/j.jmatprotec.2013.12.014

Rübner M, Günzl M, Körner C, Singer RF (2011) Aluminium–aluminium compound fabrication by high pressure die casting. Mater Sci Eng A 528(22):7024–7029. https://doi.org/10.1016/j.msea.2011.05.076

Ghomashchi M, Vikhrov A (2000) Squeeze casting: an overview. J Mater Process Technol 101(1):1–9

Liu T, Wang Q, Sui Y, Wang Q, Ding W (2015) An investigation into aluminum–aluminum bimetal fabrication by squeeze casting. Mater Des 68:8–17. https://doi.org/10.1016/j.matdes.2014.11.051

Zhang Y, Ji S, Scamans G, Fan Z (2017) Interfacial characterisation of overcasting a cast Al-Si-Mg (A356) alloy on a wrought Al-Mg-Si (AA6060) alloy. J Mater Process Technol 243:197–204. https://doi.org/10.1016/j.jmatprotec.2016.12.022

Haider KMA, Mufti NA (2014) Mechanical and microstructural evaluation of squeeze cast Al-4% Cu alloy using a full-factorial experimental design. JOM 66(8):1446–1453. https://doi.org/10.1007/s11837-014-0973-4

Souissi N, Souissi S, Lecompte JP, Amar MB, Bradai C, Halouani F (2015) Improvement of ductility for squeeze cast 2017 A wrought aluminum alloy using the Taguchi method. Int J Adv Manuf Technol 78(9–12):2069–2077. https://doi.org/10.1007/s00170-015-6792-0

Vijian P, Arunachalam V (2007) Optimization of squeeze casting process parameters using Taguchi analysis. Int J Adv Manuf Technol 33(11):1122–1127. https://doi.org/10.1007/s00170-006-0550-2

Senthil P, Amirthagadeswaran K (2012) Optimization of squeeze casting parameters for non symmetrical AC2A aluminium alloy castings through Taguchi method. J Mech Sci Technol 26(4):1141–1147. https://doi.org/10.1007/s12206-012-0215-z

Vijian P, Arunachalam V (2007) Modelling and multi objective optimization of LM24 aluminium alloy squeeze cast process parameters using genetic algorithm. J Mater Process Technol 186(1):82–86. https://doi.org/10.1016/j.jmatprotec.2006.12.019

Senthil P, Amirthagadeswaran K (2014) Experimental study and Squeeze Casting Process Optimization for High Quality AC2A Aluminium Alloy Castings. Arab J Sci Eng (Springer Science & Business Media BV) 39(3)

Patel GM, Krishna P, Parappagoudar MB (2014) Optimization of squeeze cast process parameters using Taguchi and grey relational analysis. Procedia Technol 14:157–164. https://doi.org/10.1016/j.protcy.2014.08.021

Manjunath Patel G, Krishna P, Parappagoudar MB (2016) Modelling and multi-objective optimisation of squeeze casting process using regression analysis and genetic algorithm. Aust J Mech Eng 14(3):182–198. https://doi.org/10.1080/14484846.2015.1093231

Patel GCM, Krishna P, Parappagoudar M (2015) Modelling of squeeze casting process using design of experiments and response surface methodology. Int J Cast Met Res 28(3):167–180. https://doi.org/10.1179/1743133614Y.0000000144

Sarfraz S, Jahanzaib M, Wasim A, Hussain S, Aziz H (2017) Investigating the effects of as-casted and in situ heat-treated squeeze casting of Al-3.5% Cu alloy. Int J Adv Manuf Technol 89(9–12):3547–3561. https://doi.org/10.1007/s00170-016-9350-5

Patel GM et al (2014) Investigation of squeeze cast process parameters effects on secondary dendrite arm spacing using statistical regression and artificial neural network models. Procedia Technol 14:149–156. https://doi.org/10.1016/j.protcy.2014.08.020

Patel M, Krishna P, Parappagoudar MB (2015) Prediction of secondary dendrite arm spacing in squeeze casting using fuzzy logic based approaches. Arch Foundry Eng 15(1):51–68

Karnik S, Gaitonde V, Davim J (2008) A comparative study of the ANN and RSM modeling approaches for predicting burr size in drilling. Int J Adv Manuf Technol 38(9):868–883. https://doi.org/10.1007/s00170-007-1140-7

Montgomery DC (2017) Design and analysis of experiments. John Wiley & Sons

Manjunath Patel GC, Krishna P, Parappagoudar MB (2016) Squeeze casting process modeling by a conventional statistical regression analysis approach. Appl Math Model 40(15):6869–6888

Dursun T, Soutis C (2014) Recent developments in advanced aircraft aluminium alloys. Mater Des 56:862–871. https://doi.org/10.1016/j.matdes.2013.12.002

Qi G, Chen X, Shao Z (2002) Influence of bath chemistry on zincate morphology on aluminum bond pad. Thin Solid Films 406(1):204–209. https://doi.org/10.1016/S0040-6090(01)01714-X

Saito M, Maegawa T, Homma T (2005) Electrochemical analysis of zincate treatments for Al and Al alloy films. Electrochim Acta 51(5):1017–1020. https://doi.org/10.1016/j.electacta.2005.05.063

Teng L et al (2015) Microstructure and mechanical properties of overcast aluminum joints. Trans Nonferrous Metals Soc China 25(4):1064–1072

Kasman Ş, Saklakoglu IE (2012) Determination of process parameters in the laser micromilling application using Taguchi method: a case study for AISI H13 tool steel. Int J Adv Manuf Technol 58(1):201–209. https://doi.org/10.1007/s00170-011-3371-x

Mia M, Razi MH, Ahmad I, Mostafa R, Rahman SMS, Ahmed DH, Dey PR, Dhar NR (2017) Effect of time-controlled MQL pulsing on surface roughness in hard turning by statistical analysis and artificial neural network. Int J Adv Manuf Technol 91(1–13):3211–3223. https://doi.org/10.1007/s00170-016-9978-1

Hassan M, Othman A, Kamaruddin S (2017) The use of response surface methodology (RSM) to optimize the acid digestion parameters in fiber volume fraction test of aircraft composite structures. Int J Adv Manuf Technol 90(9–12):3739–3748. https://doi.org/10.1007/s00170-016-9683-0

Deng J (1988) Essential topics on grey system: theory and applications. China Ocean Press

Mia M, Bashir MA, Khan MA, Dhar NR (2017) Optimization of MQL flow rate for minimum cutting force and surface roughness in end milling of hardened steel (HRC 40). Int J Adv Manuf Technol 89(1–4):675–690. https://doi.org/10.1007/s00170-016-9080-8

Mia M, Dhar NR (2016) Response surface and neural network based predictive models of cutting temperature in hard turning. J Adv Res 7(6):1035–1044. https://doi.org/10.1016/j.jare.2016.05.004

Bouacha K, Yallese MA, Mabrouki T, Rigal JF (2010) Statistical analysis of surface roughness and cutting forces using response surface methodology in hard turning of AISI 52100 bearing steel with CBN tool. Int J Refract Met Hard Mater 28(3):349–361. https://doi.org/10.1016/j.ijrmhm.2009.11.011

Jahanzaib M, Hussain S, Wasim A, Aziz H, Mirza A, Ullah S (2017) Modeling of weld bead geometry on HSLA steel using response surface methodology. Int J Adv Manuf Technol 89(5–8):2087–2098. https://doi.org/10.1007/s00170-016-9213-0

Azam M, Jahanzaib M, Wasim A, Hussain S (2015) Surface roughness modeling using RSM for HSLA steel by coated carbide tools. Int J Adv Manuf Technol 78(5-8):1031–1041. https://doi.org/10.1007/s00170-014-6707-5

Nami H, Halvaee A, Adgi H, Hadian A (2010) Investigation on microstructure and mechanical properties of diffusion bonded Al/Mg 2 Si metal matrix composite using copper interlayer. J Mater Process Technol 210(10):1282–1289. https://doi.org/10.1016/j.jmatprotec.2010.03.015

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ali, M.A., Jahanzaib, M., Wasim, A. et al. Evaluating the effects of as-casted and aged overcasting of Al-Al joints. Int J Adv Manuf Technol 96, 1377–1392 (2018). https://doi.org/10.1007/s00170-018-1682-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1682-x