Abstract

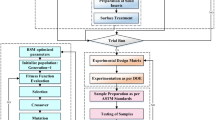

Squeeze casting has emerged as an attractive alternative for the casting of aluminum alloys to boost the mechanical and microstructural attributes. However, the alloys practiced in structural applications where ductility is considered a key characteristic, additional heat treatment processes are opted after casting. Considering the industrial applications of Al7050, the current study focused on manufacturing defect-free casting for structural applications. For this purpose, three key process variables including squeeze pressure (SP), melt temperature (MT) and die temperature (DT) have been preferred to improve the percentage elongation, ultimate tensile strength and hardness with minimal casting defects. Annealing treatment is preferred to further advance the ductile behavior of the squeeze-casted Al7050 alloy. Among different process variables, SP has a significant contribution in raising the mechanical properties followed by MT and DT. Taguchi-based Grey relational analysis (GRA) has been used to attain the optimal level of input parameters (SP = 135 MPa, MT, 740 °C and DT = 240 °C) for the superior microstructural and mechanical attributes simultaneously. Microstructural investigations revealed that application of high SP and DT with reasonable MT significantly improved the grain structure and minimized the typical casting defects including micro-voids, porosity and shrinkage cavities. Annealing treatment has been observed productive for improving ductility and reducing the casting defects specifically micro-porosity.

Similar content being viewed by others

Availability of data and materials

The paper has no associated data.

Abbreviations

- SP:

-

Squeeze pressure

- MT:

-

Melt temperature

- DT:

-

Die temperature

- UTS:

-

Ultimate tensile strength

- EL:

-

Percentage elongation

- ANOVA:

-

Analysis of variance

- GRA:

-

Grey relational analysis

References

Shin J, et al. Castability and mechanical properties of new 7xxx aluminum alloys for automotive chassis/body applications. J Alloy Compd. 2017;698:577–90.

Raza MH, et al. Investigating the effects of gating design on mechanical properties of aluminum alloy in sand casting process. J King Saud Univ Eng Sci. 2021;33(3):201–12.

Raza MH, et al. Modeling of the mechanical properties of directionally solidified Al-4.3% Cu alloy using response surface methodology. Int J Adv Manuf Technol. 2019;103(9):3913–25.

Xinyu C, et al. Composition design of 7XXX aluminum alloys optimizing stress corrosion cracking resistance using machine learning. Mater Res. 2020;7(4): 046506.

Jahangiri A, et al. The effect of pressure and pouring temperature on the porosity, microstructure, hardness and yield stress of AA2024 aluminum alloy during the squeeze casting process. J Mater Process Technol. 2017;245:1–6.

Adithiyaa T, Chandramohan D, Sathish T. Optimal prediction of process parameters by GWO-KNN in stirring-squeeze casting of AA2219 reinforced metal matrix composites. Mater Today Proc. 2020;21:1000–7.

Liu T, et al. An investigation into aluminum–aluminum bimetal fabrication by squeeze casting. Mater Des. 2015;68:8–17.

Ali MA, et al. Evaluating the effects of as-casted and aged overcasting of Al-Al joints. Int J Adv Manuf Technol. 2018;96(1):1377–92.

Kridli GT, Friedman PA, Boileau JM. 7—manufacturing processes for light alloys. In: Mallick PK, editor. Materials, design and manufacturing for lightweight vehicles. Sawston: Woodhead Publishing; 2010. p. 235–74.

Chong L, et al. Influence of high pressure and manganese addition on Fe-rich phases and mechanical properties of hypereutectic Al−Si alloy with rheo-squeeze casting. Trans Nonferrous Met Soc China. 2019;29(2):253–62.

Ali MA, et al. Mechanical characterization of aged AA2026-AA2026 overcast joints fabricated by squeeze casting. Int J Adv Manuf Technol. 2020;107(7):3277–97.

Zhou B, et al. Hot cracking tendency test and simulation of 7075 semi-solid aluminium alloy. Trans Nonferrous Met Soc China. 2020;30(2):318–32.

Li Y, Yang H, Xing Z. Numerical simulation and process optimization of squeeze casting process of an automobile control arm. Int J Adv Manuf Tchnol. 2017;88(1):941–7.

Senthil P, Amirthagadeswaran KS. Experimental study and squeeze casting process optimization for high quality AC2A aluminium alloy castings. Arab J Sci Eng. 2014;39(3):2215–25.

Natrayan L, Kumar MS, Palanikumar K. Optimization of squeeze cast process parameters on mechanical properties of Al2O3/SiC reinforced hybrid metal matrix composites using taguchi technique. Mater Res Express. 2018;5(6): 066516.

Patel GCM, Shettigar AK, Parappagoudar MB. A systematic approach to model and optimize wear behaviour of castings produced by squeeze casting process. J Manuf Process. 2018;32:199–212.

Karthik A, et al. The optimization of squeeze casting process parameter for AA2219 alloy by using the Taguchi method. Mater Today Proc. 2020;27:2556–61.

Zhang P, et al. Analysis on the tool wear behavior of 7050–T7451 aluminum alloy under ultrasonic elliptical vibration cutting. Wear. 2021;466–467: 203538.

Edalati K, Horita Z, Valiev RZ. Transition from poor ductility to room-temperature superplasticity in a nanostructured aluminum alloy. Sci Rep. 2018;8(1):6740.

Ali MA, Ishfaq K, Jawad M. Evaluation of surface quality and mechanical properties of squeeze casted AA2026 aluminum alloy using response surface methodology. Int J Adv Manuf Technol. 2019;103(9):4041–54.

Wang B, et al. Effects of cold rolling and heat treatment on microstructure and mechanical properties of AA 5052 aluminum alloy. Trans Nonferrous Met Soc China. 2015;25(8):2481–9.

Park JM, et al. Effect of annealing heat treatment on microstructural evolution and tensile behavior of Al0.5CoCrFeMnNi high-entropy alloy. Mater Sci Eng A. 2018;728:251–8.

Ma P, et al. Influence of annealing on mechanical properties of Al-20Si processed by selective laser melting. Metals. 2014;4(1):28–36.

Ghiaasiaan R, Zeng X, Shankar S. Controlled diffusion solidification (CDS) of Al-Zn-Mg-Cu (7050): microstructure, heat treatment and mechanical properties. Mater Sci Eng A. 2014;594:260–77.

Prashanth KG, et al. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: effect of heat treatment. Mater Sci Eng A. 2014;590:153–60.

Masemola K, Popoola P, Malatji N. The effect of annealing temperature on the microstructure, mechanical and electrochemical properties of arc-melted AlCrFeMnNi equi-atomic high entropy alloy. J Mark Res. 2020;9(3):5241–51.

Imran M. ARA Khan, Characterization of Al-7075 metal matrix composites: a review. J Mater Res Technol. 2019;8(3):3347–56.

Mao Z, et al. Effects of annealing temperature on the interfacial microstructure and bonding strength of Cu/Al clad sheets produced by twin-roll casting and rolling. J Mater Process Technol. 2020;285: 116804.

Maj J, et al. Effect of microstructure on mechanical properties and residual stresses in interpenetrating aluminum-alumina composites fabricated by squeeze casting. Mater Sci Eng A. 2018;715:154–62.

Kaiser R, et al. The influence of cooling conditions on grain size, secondary phase precipitates and mechanical properties of biomedical alloy specimens produced by investment casting. J Mech Behav Biomed Mater. 2013;24:53–63.

Christy JV, et al. Processing, properties, and microstructure of recycled aluminum alloy composites produced through an optimized stir and squeeze casting processes. J Manuf Process. 2020;59:287–301.

Raza MH, et al. Investigation of surface roughness in face milling processes. Int J Adv Manuf Technol. 2020;111(9):2589–99.

Zou Y. Phase equilibria and solidification of Al rich Al-Cu-Mg alloys. PhD Thesis. University of Wisconsin, Madison. 1997.

Campbell J. Complete casting handbook: metal casting processes, metallurgy, techniques and design. Oxford: Butterworth-Heinemann; 2015.

Tong X, Zhang H, Li DY. Effect of annealing treatment on mechanical properties of nanocrystalline α-iron: an atomistic study. Sci Rep. 2015;5(1):8459.

Hassasi SA, Abbasi M, Hosseinipour SJ. Parametric investigation of squeeze casting process on the microstructure characteristics and mechanical properties of A390 aluminum alloy. Int J Metalcast. 2020;14(1):69–83.

Zu-de Z. Solid-liquid forming theory and technology of composites. Beijing: Metallurgical Industry Press; 2008.

Bin S-B, et al. Influence of technical parameters on strength and ductility of AlSi9Cu3 alloys in squeeze casting. Trans Nonferrous Met Soc China. 2013;23(4):977–82.

Liu X, Zhao Q, Jiang Q. Effects of cooling rate and TiC nanoparticles on the microstructure and tensile properties of an Al–Cu cast alloy. Mater Sci Eng A. 2020;790: 139737.

Zhang K, Fu Z. Effects of annealing treatment on properties of CoCrFeNiTiAlx multi-component alloys. Intermetallics. 2012;28:34–9.

Zheng YG, et al. Roles of grain boundary and dislocations at different deformation stages of nanocrystalline copper under tension. Phys Lett A. 2009;373(5):570–4.

Kumar R, Nicola L, Van der Giessen E. Density of grain boundaries and plasticity size effects: a discrete dislocation dynamics study. Mater Sci Eng A. 2009;527(1):7–15.

Hajjari E, Divandari M. An investigation on the microstructure and tensile properties of direct squeeze cast and gravity die cast 2024 wrought Al alloy. Mater Des. 2008;29(9):1685–9.

Chen S-Y, et al. Effects of melt temperature on as-cast structure and mechanical properties of AZ31B magnesium alloy. Trans Nonferrous Met Soc China. 2013;23(6):1602–9.

Tajally M, Emadoddin E. Mechanical and anisotropic behaviors of 7075 aluminum alloy sheets. Mater Des. 2011;32(3):1594–9.

Raji A, Khan RH. Effects of pouring temperature and squeeze pressure on Al-8% Si alloy squeeze cast parts. AU JT. 2006;9(4):229–37.

Souissi N, et al. Optimization of squeeze casting parameters for 2017 a wrought Al alloy using Taguchi method. Metals. 2014;4(2):141–54.

Xiaowu HU, Fanrong AI, Hong YA. Influences of pouring temperature and cooling rate on microstructure and mechanical properties of casting Al-Si-Cu aluminum alloy. Acta Metall Sin (English Letters). 2012;25(4):272–8.

Gurusamy P, Prabu SB, Paskaramoorthy R. Influence of processing temperatures on mechanical properties and microstructure of squeeze cast aluminum alloy composites. Mater Manuf Process. 2015;30(3):367–73.

Chen R-Y, et al. Effects of annealing temperature on the mechanical properties and sensitization of 5083–H116 aluminum alloy. Proc Inst Mech Eng Part L J Mater Des Appl. 2013;229(4):339–46.

Montgomery DC. Design and analysis of experiments. New York: Wiley; 2017.

Krishnaiah K, Shahabudeen P. Applied design of experiments and Taguchi methods. Delhi: PHI Learning Pvt. Ltd; 2012.

Ishfaq K, et al. Optimization of WEDM for precise machining of novel developed Al6061–7.5% SiC squeeze-casted composite. Int J Adv Manuf Technol. 2020;111(7):2031–49.

Leung WK, Raza MH, Zhong RY. Optimization of support structure in multi-articulated joints of non-assembly mechanisms. Proc CIRP. 2021;100:726–31.

Raza MH, et al. Investigating the effects of different electrodes on Al6061-SiC-7.5 wt% during electric discharge machining. Int J Adv Manuf Technol. 2018;99(9):3017–34.

Raza MH, et al. Cryogenic treatment analysis of electrodes in wire electric discharge machining of squeeze casted Al2024/Al2O3/W composite. Int J Adv Manuf Technol. 2021;116(3):1179–98.

Wojciechowski S, et al. Application of signal to noise ratio and grey relational analysis to minimize forces and vibrations during precise ball end milling. Precis Eng. 2018;51:582–96.

Raza MH, et al. Grain selection and crystal orientation in single-crystal casting: state of the art. Cryst Res Technol. 2019;54(2):1800177.

Funding

This study has not received any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mufti, N.A., Islam, M.u., Ali, M.A. et al. Analysis of annealing on the micro-porosity and ductility of squeeze-casted Al7050 alloy for the structural applications. Archiv.Civ.Mech.Eng 22, 107 (2022). https://doi.org/10.1007/s43452-022-00428-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00428-2