Abstract

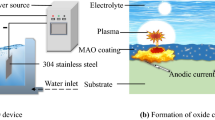

A composite oxidized layer formed on a nanocrystallized 2618 aluminum alloy surface was prepared by a two-step method—the micro-arc oxidation (MAO) process and a pretreatment of the ultrasonic cold forging technology (UCFT). The tribological properties of samples were investigated under 25, 80, 160, and 200 °C by an MST-400 high temperature tribometer. The wear performance of MAO + UCFT aluminum alloy drilling rods was evaluated in the field drilling experiment. The morphologies and microstructures were measured by the scanning electron microcopy and optical microscope. The results show that UCFT treatment promotes the formation of αAl2O3 phase, reduces the number of micro pores, and improves the hardness of MAO coatings. Both friction coefficients and wear rates of untreated and UCFT samples increase with the rise of temperature, but those of the UCFT samples are lower at the same temperature. The friction coefficients and wear rates of MAO and MAO + UCFT samples decrease with the rise of temperature, but those of the MAO + UCFT samples are lower at the same temperature. The main wear mechanism of untreated samples is severe adhesive wear, plastic deformation, and slight abrasive wear. Whereas, that of UCFT samples is some degree of adhesive wear, abrasive wear, and plastic deformation. Additionally, oxidative wear occurred on the untreated and UCFT samples. The main wear mechanism of MAO samples and MAO + UCFT samples is mild adhesive wear and abrasive wear.

Similar content being viewed by others

References

Liang J, Sun JH, Li XM et al (2014) Development and application of aluminum alloy drill rod in geologic drilling. Process Eng 73:84–90

Yan TN, Xue W, Lu CH (2010) Superiorities of aluminum alloy drilling pipe and its application prospects in deep holes for geological exploration. Explor Eng 37(2):27–29

Anohymous (2013) Aluminum-alloy pipe lightens drill string. Manuf Eng 149:33–34

Liang J, Peng L, Sun JH et al (2011) Development of aluminum alloy drill rod material in geological drilling and the indoor experimental study. Geo Explor 47(2):304–308

Hao R (1989) Drilling engineering. Petroleum Industry Press, Beijing, pp 107–140

Wang D, Zhang W, Tang SR (1995) The general situation and characteristics of Russian scientific drilling technology-the fourth of the technical visit serial reporting. Explor Eng 4:53–56

Rao RN, Das S, Mondal DP et al (2009) Dry sliding wear behaviour of cast high strength aluminum alloy (Al-Zn-Mg) and hard particle composites. Wear 267:1688–1695

Wang LL, Cai JQ, Zhou J et al (2009) Characteristics of the friction between aluminium and steel at elevated temperatures during ball-on-disc tests. Tribo Lett 36(2):183–190

Singh J, Alpas AT (1996) High-temperature wear and deformation processes in metal matrix composites. Metall Mater Trans A 27A:3135–3148

Canadic D, Maier HJ, Gabor P, May J (2008) Mater Sci Eng A 496:114

Kumar S, Pandey R, Panwar RS, Pandey OP (2013) Effect of particle size on wear of particulate reinforced aluminum alloy composites at elevated temperatures. J Mater Eng Perform 22(11):3550–3560

Wang SX, Zhao Q, Liu DX, Du N (2015) Microstructure and elevated temperature tribological behavior of TiO2/Al2O3 composite ceramic coating formed by microarc oxidation of Ti6Al4V alloy. Surf Coat Technol 272:343–349

Tang Y, Xu JY, Ye FY (2012) Antiwear behavior of micro-arc oxidated coating rubbing on abrasive paper. Mater Sci Forum 704-705:1210–1215

Lv XR, Wang SG, Liu Y, Long K, Li S (2008) Effect of nanocrystallization on tribological behaviors of ingot iron. Wear 264:535–541

Arslan E (2009) High temperature wear behavior of aluminum oxide layers produced by AC microarc oxidation. Surf Coat Technol 204:829–833

Lee JM, Kang SB, Han JM (2008) Dry sliding wear of MAO-coated A356/20vol. % SiCp composites in the temperature range 25-180°C. Wear 264:75–85

Jiang YF, Zhang YY, Bao YF et al (2011) Dry sliding wear behaviours of intrinsically sintered micro-arc oxidation coatings on pure aluminum. Adv Mater Res 154-155:1000–1003

Amanov A (2013) Improvement of the tribological properties of Al 6061-T6 alloy under dry sliding conditions. Tribo Int 64:24–32

Wang YY, Yue W, She DS et al (2014) Effects of surface nanocrystallization on tribological properties of 316L stainless steel under MoDTC/ZDDP lubrications. Tribo Int 79:42–51

Cao XJ, Pyoun YS, Murakami R (2010) Fatigue properties of a S45C steel by subjected to ultrasonic nanocrystal surface modification. Appl Surf Sci 256:6297–6303

Shen DJ, Cai JR (2013) Effcet of ultrasonic on microstructure and growth characteristics of micro-arc oxidation ceramic coatings on 6061 aluminum alloy. Vacuum 99:143–148

Chen LL, Gu YH, Liu L et al (2015) Effect of ultrasonic cold forging technology as the pretreatment on the corrosion resistance of MAO Ca/P coating on AZ31B Mg alloy. J Alloys Compd 635:278–288

Cheng ML, Zhang DY, Chen HW, Qin W, Li JS (2016) Surface nanocrystallization and its effect on fatigue performance of high-strength materials treated by ultrasonic rolling process. Int J Adv Manuf Technol 83:123–131

Ma GZ, Xu BS, Wang HD, Si HJ, Yang DX (2011) Effect of surface nanocrystallization on the tribological properties of 1Cr18Ni9Ti stainless steel. Mater Lett 65:1268–1271

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOC 9695 kb)

Rights and permissions

About this article

Cite this article

Yi, P., Yue, W., Liang, J. et al. Effects of nanocrystallized layer on the tribological properties of micro-arc oxidation coatings on 2618 aluminum alloy under high temperatures. Int J Adv Manuf Technol 96, 1635–1646 (2018). https://doi.org/10.1007/s00170-017-0831-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0831-y