Abstract

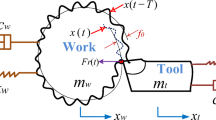

The paper focuses on the chatter stability prediction for a flexible tool-workpiece system in a turning process. The dynamic model of the turning process presented here considers two end conditions of the flexible workpiece. Chatter-free (stable) cutting parameters are obtained analytically and stability lobe diagrams (SLDs) of a turning operation are constructed using simulations to distinguish stable and unstable regions. The SLDs are constructed for a variety of tool and workpiece parameters affecting the flexibility/compliance of the tool-workpiece system to investigate the effects of these parameters on the stability of the turning process. The proposed analytical model has been validated with the turning experimental results.

Similar content being viewed by others

References

Taylor F (1907) On the art of cutting metals. Transactions of ASME 28(31–350)

Tobias SA, Fishwick W (1958) The chatter of lathe tools under orthogonal cutting conditions. Transactions of ASME 80:1079–1088

Tlusty J, Polacek M (1963) The stability of machine tools against self excited vibrations in machining. In: Proceedings of the International Research in Production Engineering Conference. Pittsburgh, PA, ASME, New York, pp 465–474

Siddhpura M, Paurobally R (2012a) A review of chatter vibration research in turning. Int J Mach Tools Manuf 61(0):27–47. doi:10.1016/j.ijmachtools.2012.05.007

Siddhpura A, Paurobally R (2012b) A review of flank wear prediction methods for tool condition monitoring in a turning process. Int J Adv Manuf Technol:1–23. doi:10.1007/s00170-012-4177-1

Siddhpura A, Paurobally R (2012c) A study of the effects of friction on flank wear and the role of friction in tool wear monitoring. Aust J Mech Eng 10(2):141–156

Meritt HE (1965) Theory of self-excited machine-tool chatter. Transactions of the ASME Journal of Engineering for Industry 87(4):447–454

Tobias SA (1961) Machine tool vibration research. International Journal of Machine Tool Design and Research 1(1–2):1–14

Tlusty J (1999) Manufacturing processes and equipment. Prentice Hall, NJ

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53(2):619–642

Shanker A (1976) An analysis of chatter vibration while turning slender workpieces between centres. Annals of CIRP 25(1):273–276

Benardos PG, Mosialos S, Vosniakos GC (2006) Prediction of workpiece elastic deflections under cutting forces in turning. Robot Comput Integr Manuf 22(5–6):505–514. doi:10.1016/j.rcim.2005.12.009

Chen CK, Tsao YM (2006a) A stability analysis of regenerative chatter in turning process without using tailstock. Int J Adv Manuf Technol 29(7):648–654

Chen CK, Tsao YM (2006b) A stability analysis of turning a tailstock supported flexible work-piece. Int J Mach Tools Manuf 46(1):18–25

Vela-Martínez L, Jáuregui-Correa JC, Rubio-Cerda E, Herrera-Ruiz G, Lozano-Guzmán A (2008) Analysis of compliance between the cutting tool and the workpiece on the stability of a turning process. Int J Mach Tools Manuf 48(9):1054–1062

Sekar M, Srinivas J, Kotaiah K, Yang S (2009) Stability analysis of turning process with tailstock-supported workpiece. Int J Adv Manuf Technol 43(9):862–871

Urbikain G, López de Lacalle LN, Campa FJ, Fernández A, Elías A (2012) Stability prediction in straight turning of a flexible workpiece by collocation method. Int J Mach Tools Manuf 54–55(0):73–81. doi:10.1016/j.ijmachtools.2011.11.008

Timoshenko S (1968) Elements of strength of materials, 5th edn. Van Nostrand, Princeton, N.J

Cheng K (ed) (2008) Machining dynamics: fundamentals, applications and practices. Springer Science & Business Media, Berlin

Altintas Y (2000) Manufacturing automation: principles of metal cutting and machine tool vibrations. Cambridge, New York

Siddhpura M, Paurobally R (2013a) Chatter stability and tool wear predictions in the presence of chatter vibrations for orthogonal turning process. Aust J Mech Eng 11(2):67–82

Siddhpura, M., & Paurobally, R. (2013b) Experimental investigation of chatter vibrations in facing and turning processes. In Proceedings of World Academy of Science, Engineering and Technology (No. 78, p. 62). World Academy of Science, Engineering and Technology (WASET), Canada

Siddhpura, M. A. (2013a). Analytical modelling and experimental verification of facing and turning processes for chatter stability and tool wear predictions.

Siddhpura, A. M. (2013b). Modelling, simulation and experimental validation of tool flank wear during orthogonal turning process with stick-slip vibrations. Thesis (Ph.D.)--University of Western Australia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siddhpura, M., Siddhpura, A. & Paurobally, R. Chatter stability prediction for a flexible tool-workpiece system in a turning process. Int J Adv Manuf Technol 92, 881–896 (2017). https://doi.org/10.1007/s00170-017-0208-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0208-2