Abstract

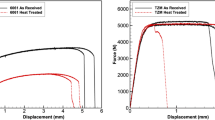

In this study, a successive double sided laser beam welding process was used to join dissimilar aluminum alloys, AA2024-O and AA7075-T6 using a low power Yb-fiber laser in a T-joint configuration without additions of filler materials. The influence of welding speeds and focal distances were evaluated. First, the welding speeds were varied from 12 mm/s to 21 mm/s at a constant laser power of 270W. Optical microscopic observations have shown that the minimum gap line of 0.8mm was obtained at a laser welding speed of 12mm/s, while the maximum gap line of 1.8mm was obtained at a laser welding speed of 21mm/s. The focal distance with offsets of -1, 0 and +1 at welding speed 18mm/s were evaluated, showing variations in the gap line. Vickers microhardness evaluation across the welding region showed the hardness values at the fusion and heat affected zones were lower than those of the base metals when welding speed varied. Meanwhile, the Vickers microhardness increases when focal distance is defocused +1. The pull test showed the force needed to fracture the welded specimens increased from 101N to 427N as the welding speed decreased from 21mm/s to 12mm/s. For constant welding speed and laser power, the fracture force increased from 100N to 400N as the focal distance changes from -1 to +1. It was observed that a lower welding speed and positive offset value of focal distance will result in deeper penetration, leading to better weld quality between alloys AA2xxx and AA7xxx.

Similar content being viewed by others

References

Enz J, Khomenko V, Riekehr S, Ventzke V, Huber N, Kashaev N (2015) Single-sided laser beam welding of a dissimilar AA2024-AA7050 T-joint. Mater Design 76:110–116. doi:10.1016/j.matdes.2015.03.049

Li M, Li ZG, Zhao Y, Li H, Wang YH, Huang J (2011) Influence of welding parameters on weld formation and microstructure of dual-laser beams welded T-joint of aluminum alloy. Adv Mater Sci Eng. doi:10.1155/2011/767260

Ion JC (2000) Laser beam welding of wrought aluminium alloys. Sci Technol Weld Joi 5(5):265–276. doi:10.1179/136217100101538308

Pinto LA, Quintino L, Miranda RM, Carr P (2010) Laser welding of dissimilar aluminium alloys with filler materials. Weld World 54(11-12):R333–R341. doi:10.1007/BF03266747

Elrefaey A, Ross NG (2015) Microstructure and mechanical properties of cold metal transfer welding similar and dissimilar aluminum alloys. Acta Metallurgica Sinica (English Letters) 28(6):715–724. doi:10.1007/s40195-015-0252-6

Kim TW, Park YW (2011) Parameter optimization using a regression model and fitness function in laser welding of aluminum alloys for car bodies. Int J Precis Eng Man 12(2):313–320. doi:10.1007/s12541-011-0041-8

Zhu J, Li L, Liu Z (2004) C02 and diode laser welding of 5182 sheet aluminum alloy. In: Hinduja S (ed) Proceedings of the 34th International MATADOR Conference: Formerly the international machine tool design and conferences. Springer London, London, pp. 253–258. doi:10.1007/978-1-4471-0647-0_38

Alfieria V, Caiazzoa F, Sergi V (2015) Autogenous laser welding of AA 2024 aluminium alloy: Process issues and bead features. Procedia CIRP 33:406–411. doi:10.1016/j.procir.2015.06.094

Caiazzo F, Alfieri V, Cardaropoli F, Sergi V (2013) Butt autogenous laser welding of AA 2024 aluminium alloy thin sheets with a Yb:YAG disk laser. Int J Adv Manuf Tech 67(9-12):2157–2169. doi:10.1007/s00170-012-4637-7

Sheikhi M, Ghaini FM, Assadi H (2015) Prediction of solidification cracking in pulsed laser welding of 2024 aluminum alloy. Acta Mater 82:491–502. doi:10.1016/j.actamat.2014.09.002

Unt A, Salminen A (2015) Effect of welding parameters and the heat input on weld bead profile of laser welded T-joint in structural steel. J Laser Appl 27. doi:10.2351/1.4906378

Tavares SMO, Azevedo PCM, Emilio B, Richter-Trummer V, Figueiredo MAV, Vilaca P, de Castro PMST (2009) Friction stir welding of T-joints in dissimilar aluminum alloys. American Society of Mechanical Engineers:265–273. doi:10.1115/IMECE2008-67522

Fratini L, Buffa G, Shivpuri R (2009) Influence of material characteristics on plastomechanics of the FSW process for T-joints. Materials and Design 30:2435–2445. doi:10.1016/j.matdes.2008.10.014

Zain-ul-Abdein M, Nelias D, Jullien JF, Deloison D (2009) Prediction of laser beam welding-induced distortions and residual stresses by numerical simulation for aeronautic application. J Mater Process Tech 209(6):2907–2917. doi:10.1016/j.jmatprotec.2008.06.051

Daneshpour S, Koçak M, Bayraktar FS, Riekehr S (2009) Damage tolerance analyses of laser welded “skin-clip” joints for aerospace applications. Weld World 53(3):90–98. doi:10.1007/BF03266707

Ventzke V, Riekehr S, Horstmann M, Haack P, Kashaev N (2014) One-sided Nd:YAG laser beam welding for the manufacture of T-joints made of aluminium alloys for aircraft construction. Welding and Cutting 13(4):245–249

Shanmugam NS, Buvanashekaran G, Sankaranarayanasamy K, Kumar SR (2010) A transient finite element simulation of the temperature and bead profiles of T-joint laser welds. Mater Design 31(9):4528–4542. doi:10.1016/j.matdes.2010.03.057

Machold WPS, Bayraktar F, Riekehr S, Koçak M, Schreyer A (2008) Influence of the welding sequence on residual stresses in laser welded T joints of an airframe aluminium alloy. Materials Science Forum 571:375–380. doi:10.4028/www.scientific.net/MSF.571-572.375

Enz J, Riekehr S, Ventzke V, Kashaev N, Huber N (2012) Process optimisation for the laser beam welding of high-strength aluminium-lithium alloys. Schweißen und Schneiden 64(8):482–485

Prisco A, Troiano G, Acerra F, Bellucci B, Squillace A, Prisco U (2008) LBW of Similar and dissimilar skin-stringer joints part i: process optimization and mechanical characterization. Adv Mater Res 38:306–319

Yang ZB, Tao W, Li LQ, Chen YB, Li FZ, Zhang YL (2012) Double-sided laser beam welded T-joints for aluminium aircraft fuselage panels: Process, microstructure, and mechanical properties. Materials and Design 33:652−–6658

Tao W, Yang ZB, Chen YB, Li LQ, Jiang ZG, Zhang YL (2013) Double-sided fiber laser beam welding process of T-joints for aluminum aircraft fuselage panels: Filler wire melting behavior, process stability, and their effects on porosity defects. Opt Laser Technol 52:1–9. doi:10.1016/j.optlastec.2013.04.003

Carpinteri A, Brighenti R, Huth HJ, Vantadori S (2004) Fatigue growth of a surface crack in a welded T-joint. International Journal of Fatigue 27(1):59–69. doi:10.1016/j.ijfatigue.2004.05.007

Padovani C, Fratini L, Squillace A, Bellucci FE (2007) Electrochemical analysis on friction stir welded and laser welded 6XXX aluminium alloys T-joints. Corrosion Reviews 25(3-4):475–489. doi:10.1515/CORRREV.2007.25.3-4.475

Janasekaran S, Tan AW, Yusof F, Abdul Shukor M (2016) Feasibility study of low power fiber laser welding AA2024 and AA7075 alloys T-Joint. Key Engineering Materials 701:182–186

ASM I (1990) ASM Handbook Volume 2: Properties and selection: Nonferrous alloys and special-purpose materials, vol 2. ASM International

Tavares SMO, Castro RAS, Richter-Trummer V, Vilaca P, Moreira PMGP, de Castro PMST (2010) Friction stir welding of T-joints with dissimilar aluminium alloys: mechanical joint characterisation. Sci Technol Weld Joi 15(4):312–318

Janasekaran S, Tan AW, Yusof F, Abdul Shukor M (2016) Influence of the overlapping factor and welding speed on T-Joint welding of Ti6Al4V and Inconel 600 using low-power fiber laser. Metals 6(6):134. doi:10.3390/met6060134

Badini C, Pavese M, Fino P, Biamino S (2009) Laser beam welding of dissimilar aluminium alloys of 2000 and 7000 series: effect of post-welding thermal treatments on T joint strength. Sci Technol Weld Joi 14(6):484–492. doi:10.1179/136217108x372559

Katayama S (2013) Handbook of laser welding technologies, vol 1. 1 edn. Elsevier

Norris JT, Robino CV, Hirschfeld DA, Perricone MJ (2011) Effects of laser parameters on porosity formation: Investigating millimeter scale continuous wave Nd:YAG laser welds. Weld J 90(10):198

Sanchez-Amaya JM, Delgado T, De Damborenea JJ, Lopez V, Botana FJ (2009) Laser welding of AA 5083 samples by high power diode laser. Sci Technol Weld Joi 14(1):78–86. doi:10.1179/136217108x347629

Sanchez-Amaya JM, Delgado T, Gonzalez-Rovira L, Botana FJ (2009) Laser welding of aluminium alloys 5083 and 6082 under conduction regime. Appl Surf Sci 255(23):9512–9521. doi:10.1016/j.apsusc.2009.07.081

Atabaki MM, Nikodinovski M, Chenier P, Ma J, Liu W, Kovacevic R (2014) Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration. Opt Laser Technol 59:68–92. doi:10.1016/j.optlastec.2013.12.008

Ezazi M, Yusof F, Sarhan AA, Shukor MHA, Fadzil M (2015) Employment of fiber laser technology to weld austenitic stainless steel 304l with aluminum alloy 5083 using pre-placed activating flux. Mater Design 87:105–123

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Janasekaran, S., Jamaludin, M.F., Muhamad, M.R. et al. Autogenous double-sided T-joint welding on aluminum alloys using low power fiber laser. Int J Adv Manuf Technol 90, 3497–3505 (2017). https://doi.org/10.1007/s00170-016-9677-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9677-y