Abstract

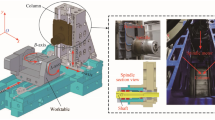

Thermal error of the spindle is one of the primary contributors of the inaccuracy of the precision machine tools. In order to study the thermal characteristics of the spindle, finite element analysis has been widely used. However, the accuracy of numerical simulation is highly dependent on the boundary conditions especially the coefficients of convection heat transfer. In this paper, the inverse heat conduction theory is introduced and used for optimizing the coefficients of convection heat transfer. Then, the temperature field and thermal error of the spindle are simulated in ANSYS. Based on the simulation results, a new method called mean impact value is proposed to select the thermal key points in the spindle system. Finally, the verification experiments are conducted on a precision horizontal machining center. By comparing the simulation results with the experimental data, the correctness and effectiveness of the heat convection coefficient optimization are verified. In addition, the results of thermal error modeling based on multiple variables including the temperatures of the thermal key points show that the result of the thermal key point selection is satisfying.

Similar content being viewed by others

References

Ramesh R, Mannan M, Poo A (2000) Error compensation in machine tools—a review: part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tools Manuf 40(9):1235–1256

Mancisidor I, Zatarain M, Munoa J, Dombovari Z (2011) Fixed boundaries receptance coupling substructure analysis for tool point dynamics prediction. Adv Mater Res 223:622–631

Huang Y, Zhang J, Li X, Tian L (2014) Thermal error modeling by integrating GA and BP algorithms for the high-speed spindle. Int J Adv Manuf Technol 1–7

Bryan J (1990) International status of thermal error research (1990). CIRP annals-manufacturing technology 39(2):645–656

Sarhan AA (2014) Investigate the spindle errors motions from thermal change for high-precision CNC machining capability. Int J Adv Manuf Technol 70(5–8):957–963

Li Y, Zhao W, Lan S, Ni J, Wu W, Lu B (2015) A review on spindle thermal error compensation in machine tools. International Journal of Machine Tools & Manufacture 95:20–38

Creighton E, Honegger A, Tulsian A, Mukhopadhyay D (2010) Analysis of thermal errors in a high-speed micro-milling spindle. Int J Mach Tools Manuf 50(4):386–393

Li B, Hong J, Tian X (2016) Generating optimal topologies for heat conduction by heat flow paths identification. International Communications in Heat & Mass Transfer 75:177–182

Postlethwaite S, Allen J, Ford D (1999) Machine tool thermal error reduction—an appraisal. Proc Inst Mech Eng B J Eng Manuf 213(1):1–9

Uhlmann E, Hu J (2012) Thermal modelling of a high speed motor spindle. Procedia CIRP 1:313–318

Xiang S, Zhu X, Yang J (2014) Modeling for spindle thermal error in machine tools based on mechanism analysis and thermal basic characteristics tests. Proc Inst Mech Eng C: J Mech Eng Sci 0954406214531219

Chen D, Bonis M, Zhang F, Dong S (2011) Thermal error of a hydrostatic spindle. Precis Eng 35(3):512–520

Zhang J, Li H (2012) Thermal performance analysis for the machine tool’s spindle. In: 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA). pp 2131–2134

Ma X, Qiu J, Liu QW, Lin J (2012) Study on Spindle Thermal Field Distribution and Thermal Errors of Horizontal Machine Tool. In: Materials Science Forum. Trans Tech Publ, pp 273–276

Han J, Wang LP, Yu LQ (2010) Modeling and estimating thermal error in precision machine spindles. Applied Mechanics and Materials 34:507–511

Haitao Z, Jianguo Y, Jinhua S (2007) Simulation of thermal behavior of a CNC machine tool spindle. Int J Mach Tools Manuf 47(6):1003–1010

Alifanov OM (2012) Inverse heat transfer problems. Springer Science & Business Media

Ozisik MN, Orlande H, Kassab AJ (2002) Inverse heat transfer: fundamentals and applications. Appl Mech Rev 55(1):B18

Wang G, Zhu L, Chen H (2011) A decentralized fuzzy inference method for solving the two-dimensional steady inverse heat conduction problem of estimating boundary condition. International Journal of Heat & Mass Transfer 54(13):2782–2788

Baş D, Boyacı İH (2007) Modeling and optimization I: usability of response surface methodology. J Food Eng 78(3):836–845

Liu Y-T, Zhang L (2016) An investigation into the aspheric ultraprecision machining using the response surface methodology. Precis Eng 44:203–210. doi:10.1016/j.precisioneng.2015.12.006

Lienhard JH (2013) A heat transfer textbook. Courier Corporation

Li Y, Zhao W Axial thermal error compensation method for the spindle of a precision horizontal machining center. In: Mechatronics and Automation (ICMA), 2012 International Conference on, 2012. IEEE, pp 2319–2323

Harris T (1991) Rolling bearing analysis. Willey, New York

Guo Q, Yang J, Wu H (2010) Application of ACO-BPN to thermal error modeling of NC machine tool. Int J Adv Manuf Technol 50(5–8):667–675

Vyroubal J (2012) Compensation of machine tool thermal deformation in spindle axis direction based on decomposition method. Precis Eng 36(1):121–127

Weck M, McKeown P, Bonse R, Herbst U (1995) Reduction and compensation of thermal errors in machine tools. CIRP Annals-Manufacturing Technology 44(2):589–598

Lo C-H, Yuan J, Ni J (1999) Optimal temperature variable selection by grouping approach for thermal error modeling and compensation. Int J Mach Tools Manuf 39(9):1383–1396

Han J, Wang L, Wang H, Cheng N (2012) A new thermal error modeling method for CNC machine tools. Int J Adv Manuf Technol 62(1–4):205–212

Li Y, Yang J, Gelvis T, Li Y (2008) Optimization of measuring points for machine tool thermal error based on grey system theory. Int J Adv Manuf Technol 35(7–8):745–750

Yan J, Yang J (2009) Application of synthetic grey correlation theory on thermal point optimization for machine tool thermal error compensation. Int J Adv Manuf Technol 43(11–12):1124–1132

Jiang JL, Su X, Zhang H, Zhang XH, Yuan YJ (2013) A novel approach to active compounds identification based on support vector regression model and mean impact value. Chem Biol Drug Des 81(5):650–657

Zhong-guang F, Min-fang Q, Yuan J (2012) Regression forecast of main steam flow based on mean impact value and support vector regression. In: Power and Energy Engineering Conference (APPEEC), 2012 Asia-Pacific. pp 1–5. doi:10.1109/APPEEC.2012.6307580

Li Y, Zhao W, Wu W, Lu B, Chen Y (2014) Thermal error modeling of the spindle based on multiple variables for the precision machine tool. Int J Adv Manuf Technol 72(9–12):1415–1427. doi:10.1007/s00170-014-5744-4

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Zhao, W., Wu, W. et al. Boundary conditions optimization of spindle thermal error analysis and thermal key points selection based on inverse heat conduction. Int J Adv Manuf Technol 90, 2803–2812 (2017). https://doi.org/10.1007/s00170-016-9594-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9594-0