Abstract

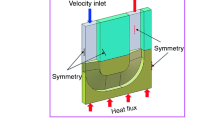

In order to improve the electrochemical machining (ECM) precision and efficiency of a closed impeller internal flow channel, the internal flow channel cathode shape and structure were optimized by gap flow field simulation. Firstly, the theoretical model and three-dimensional gap flow field simulation geometric model were set up. Next, the inter-electrode gap flow field simulation results were draw from the streamline, velocity, and pressure cloud picture. Secondly, the cathode and the frock clamp were designed according to the simulation results. Finally, the verification experiment was carried out to evaluate the cathode structure and the ECM process parameters, and the experimental results were consistent with the simulation results. The whole process is stable and no short-circuit phenomenon with the forward flow field machining pattern. The results show that the method of gap flow field simulation-assisted ECM cathode design is useful and economical for machining closed impeller internal flow channel.

Similar content being viewed by others

References

Tang L, Guo YF (2013) Influence of discharge energy parameters on S-03 high-strength steel for aerospace components. Mater Manuf Process 29(1):53–58

Kurita T, Hattori M (2006) A study of EDM and ECM/ECM-lapping complex machining technology. Int J Mach Tools Manuf 46(14):1804–1810

Klocke F, Zeis M, Klink A, Veselovac D (2013) Experimental research on the electrochemical machining of modern titanium- and nickel-based alloys for aero engine components. Procedia CIRP 6:368–372

Klocke F, Zeis M, Klink A, Veselovac D (2013) Technological and economical comparison of roughing strategies via milling, sinking-EDM, wire-EDM and ECM for titanium- and nickel-based blisks. CIRP J Manuf Sci Technol 6(3):198–203

Klocke F, Klink A, Veselovac D, Aspinwall DK, Soo SL, Schmidt M, Schilp J, Levy G, Kruth JP (2014) Turbomachinery component manufacture by application of electrochemical, electro-physical and photonic processes. CIRP Annals-Manufacturing Technology 63(2):703–726

Zhao T, Shi Y, Lin X, Duan J, Sun P, Zhang J (2014) Surface roughness prediction and parameters optimization in grinding and polishing process for IBR of aero-engine. Int J Adv Manuf Technol 74(5-8):653–663

Langmaak S, Wiseall S, Bru C, Adkins R, Scanlan J, Sóbester A (2013) An activity-based-parametric hybrid cost model to estimate the unit cost of a novel gas turbine component. Int J Prod Econ 142(1):74–88

Rajurkar KP, Sundaram MM, Malshe AP (2013) Review of electrochemical and electrodischarge machining. Procedia CIRP 6:13–26

Liu X, Kang X, Zhao W, Liang W (2013) Electrode feeding path searching for 5-axis EDM of integral shrouded blisks. Procedia CIRP 6:107–111

Chavoshi SZ, Behagh AM (2014) A note on influential control parameters for drilling of hard-to-machine steel by electrochemical discharge machining. Int J Adv Manuf Technol 71(9-12):1883–1887

Huang SF, Liu Y (2014) Electrochemical micromachining of complex shapes on nickel and nickel-based superalloys. Mater Manuf Process 29(11-12):1483–1487

Qu NS, Fang XL, Zhang YD, Zhu D (2013) Enhancement of surface roughness in electrochemical machining of Ti6Al4V by pulsating electrolyte. Int J Adv Manuf Technol 69(9-12):2703–2709

Burger M, Koll L, Werner EA, Platz A (2012) Electrochemical machining characteristics and resulting surface quality of the nickel-base single-crystalline material LEK94. J Mater Process Technol 14(1):62–70

Tang L, Guo YF (2013) Experimental study of special purpose stainless steel on electrochemical machining of electrolyte composition. Mater Manuf Process 28(4):457–462

Tang L, Yang S (2013) Experimental investigation on the electrochemical machining of 00Cr12Ni9Mo4Cu2 material and multi-objective parameters optimization. Int J Adv Manuf Technol 67(9):2909–2916

Zhang H, Xu JW (2010) Modeling and experimental investigation of laser drilling with jet electrochemical machining. Chinese J Aeronaut 23(4):454–460

Zhang Z, Feng Q, Cai M, Huang L, Jiang Y (2015) Research on stress-etching complex microstructure of aluminum alloy in laser electrochemical machining. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7354-1,1-9

Skoczypiec S (2007) Numerical investigations on ultrasonically assisted electrochemical machining process (USECM). In Proceedings of the 15th International Symposium on Electromachining, Pittsburgh, USA 339-344

Zanjani MY, Kashani HG, Mirahmadi A (2013) Improvement of electrochemical turning for machining complex shapes using a simple gap size sensor and a tubular shape tool. Int J Adv Manuf Technol 69(1-4):375–381

Zhu D, Wang W, Fang XL, Qu NS, Xu ZY (2010) Electrochemical drilling of multiple holes with electrolyte-extraction. CIRP Annals-Manufacturing Technology 59(1):239–242

Wang W, Zhu D, Qu NS, Huang SF, Fang XL (2010) Electrochemical drilling with vacuum extraction of electrolyte. J Mater Process Technol 210(2):238–244

Fang X, Qu N, Zhang Y, Xu Z, Zhu D (2014) Effects of pulsating electrolyte flow in electrochemical machining. J Mater Process Technol 214(1):36–43

Zhu D, Zhu D, Xu Z, Zhou L (2013) Trajectory control strategy of cathodes in blisk electrochemical machining. Chinese J Aeronaut 26(4):1064–1070

Xu Z, Liu J, Xu Q, Gong T, Zhu D, Qu N (2015) The tool design and experiments on electrochemical machining of a blisk using multiple tube electrodes. Int J Adv Manuf Technol 79(1-4):531–539

Zhu D, Zhang J, Zhang K, Liu J, Chen Z, Qu N (2015) Electrochemical machining on blisk cascade passage with dynamic additional electrolyte flow. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7043-0,1-9

Habib MA, Rahman M (2013) Analysis of electrolyte flow in localized electrochemical deposition. Procedia Engineering 56:766–771

Tang L, Gan W (2014) Utilization of flow field simulations for cathode design in electrochemical machining of aerospace engine blisk channels. Int J Adv Manuf Technol 72:1759–1766

Zhu D, Zhu D, Xu Z, Xu Q, Liu J (2010) Investigation on the flow field of W-shape electrolyte flow mode in electrochemical machining. J Appl Electrochem 40(3):525–532

Xu Z, Sun L, Hu Y, Zhang J (2014) Flow field design and experimental investigation of electrochemical machining on blisk cascade passage. Int J Adv Manuf Technol 71(1-4):459–469

Weißhaar K, Weinmann M, Jung A, Weber O, Natter H (2015) Replication of microstructured tools for electrochemical machining applications. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7367-9,1-13

Klocke F, Zeis M, Klink A (2015) Interdisciplinary modelling of the electrochemical machining process for engine blades. CIRP Annals-Manufacturing Technology 64:217–220

Sun C, Zhu D, Li Z, Wang L (2006) Application of FEM to tool design for electrochemical machining freeform surface. Finite Elem Anal Des 43(2):168–172

Klocke F, Zeis M, Harst S, Klink A, Veselovac D, Baumgärtner M (2013) Modeling and simulation of the electrochemical machining (ECM) material removal process for the manufacture of aero engine components. Procedia CIRP 8:265–270

Qu NS, Xu ZY (2013) Improving machining accuracy of electrochemical machining blade by optimization of cathode feeding directions. Int J Adv Manuf Technol 68(5-8):1565–1572

Uchiyama M, Kunieda M (2013) Application of large deflection analysis for tool design optimization in an electrochemical curved hole machining method. Precis Eng 37(3):765–770

Sawicki J, Paczkowski T (2012) Computer aided electrochemical shaping of curvilinear surfaces. J Polish CIMAC 7(3):261–267

Paczkowski T (2010) Numerical simulation for ECM machining of nonlinear shaped surfaces. J Polish CIMAC 5(3):121–132

Kang M, Fu X, Yang Y (2011) Research on flow field characteristics and experiments of numerical control electrochemical machining. Adv Sci Lett 4(6-7):1933–1938

Paczkowski T, Zdrojewski J (2010) Electrode tool designing in the ECM machining for curvilinear surfaces. J Machine Eng 10(1):58–69

Minazetdinov NM (2009) A scheme for the electrochemical machining of metals by a cathode tool with a curvilinear part of the boundary. J Appl Math Mech 73(5):592–598

Li ZY, Niu ZW (2007) Convergence analysis of the numerical solution for cathode design of aero-engine blades in electrochemical machining. Chinese J Aeronaut 20(6):570–576

Purcar M, Dorochenko A, Bortels L, Deconinck J, Van den Bossche B (2008) Advanced CAD integrated approach for 3D electrochemical machining simulations. J Mater Process Technol 203(1):58–71

Xu ZY, Xu Q, Zhu D, Gong T (2013) A high efficiency electrochemical machining method of blisk channels. CIRP Annals-Manufacturing Technology 62(1):187–190

Fujisawa T, Inaba K, Yamamoto M, Kato D (2008) Multiphysics simulation of electrochemical machining process for three-dimensional compressor blade. J Fluids Eng 130(8):081602–081608

Tang L, Yang F, Zhu QL, Gan WM (2016) Electrochemical machining flow field simulation and experimental verification for irregular vortex paths of a closed integer impeller. Int J Adv Manuf Technol 83(1-4):275–283. doi:10.1007/s00170-015-7475-6

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, L., Zhu, Q.L., Zhao, J.S. et al. Research on the cathode design and experiments of electrochemical machining a closed impeller internal flow channel. Int J Adv Manuf Technol 88, 2517–2525 (2017). https://doi.org/10.1007/s00170-016-8976-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8976-7