Abstract

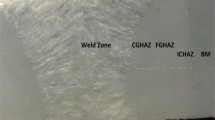

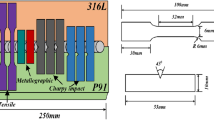

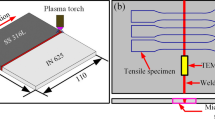

Welding of powder metallurgy (P/M) materials continues to be challenging due to the complexities in terms of thermal and metallurgical processes as a result of porosity. Though fusion welding may reduce or totally eliminate porosity levels in the weld zone, metallurgical changes in the heat-affected zone (HAZ) and PMZ may pose problems relating to strength of the welded joints. The present research work aims to study the mechanical and metallurgical changes in a sinter-forged pre-alloy Atomet 4601 (Fe-0.54 % molybdenum (Mo)-1.8 % nickel (Ni)+0.3 %C) low alloy steel subjected to tungsten inert gas (TIG) welding. Green cylindrical compacts were sintered in a nitrogen-purged muffle furnace at a temperature of 1120 °C for 20 min and subjected to cold upsetting to get various densities of specimens. TIG welding was performed on the forged alloy steel plates with suitable filler material. The TIG-welded alloy steel was subjected to tensile and micro hardness tests, in addition to micro-examination and SEM fractographs of the fractured surfaces. Weld metal porosity has been observed in the case of parent metals with lower density. Increasing the density of alloy steel is found to enhance the tensile strength of parent metal and welded joint of alloy steels—partly due to absence of weld metal porosity. Formation of lamellar acicular ferrite at the fusion zone makes the welded joint stronger than the parent metal. The SEM image of fractured surface reveals brittle mode of fracture of the welded joint during tensile testing.

Similar content being viewed by others

References

Hamill J (2007) Powder metallurgy welding and joining processes. PM Asia International Conference, Shanghai

Selcuk C, Bond S, Woollin P (2010) Joining processes for powder metallurgy parts: a review. Powder Metall 53(1):7–11

Correa EO, Costa SC, Santos JN (2008) Weldability of iron-based powder metal materials using pulsed plasma arc welding process. J Mater Process Technol 198:323–329

Correa EO, Costa SC, Santos JN (2009) Studies on weldability of iron-based powder metal alloys using pulsed gas tungsten arc welding process. J Mater Process Technol 209:3937–3942

Mural Y, Isako H (1995) Joint properties of sintered steel parts by laser welding. Kobe Res Dev 45(1):49–52

Arivazhagan N, Singh S, Prakash S, Reddy GM (2011) Investigation on AISI 304 austenitic stainless steel to AISI 4140 low alloy steel dissimilar joints by gas tungsten arc, electron beam and friction welding. Mater Des 32:3036–3050

Cao X, Wanjara P, Huang J, Munro C, Nolting A (2011) Hybrid fibre laser-arc welding of thick section high strength low alloy steel. Mater Des 32:3399–3413

Mehta Y, Trivedi S, Chandra K, Mishra PS (2010) Studies on weldability of powder processed Fe-0.35P-0.15C alloy using gas tungsten arc welding process. J Miner Mater Charact Eng 9(3):211–229

Mathusudhan Redddy G, Mohandas T, Tagore GRN (1995) Weldability studies of high- strength low alloy steel using austenitic fillers. J Mater Process Technol 49:213–228

Lakshiminarayanan AK, Shanmugam K, Balasubramanian V (2009) Effect of autogenous arc welding process on tensile and impact properties of ferritic stainless steel joints. J Iron Steel Res Int 16(1):62–68

Tseng K-H, Chuang K-J (2012) Application of iron-based powders in tungsten inert gas welding for 17Cr-10Ni- 2Mo alloys. Powder Technol 228:36–46

Wang J, Lu M-x, Zhang L, Chang W, Xu L-n, Hu L-h (2012) Effect of welding process on the microstructure and properties of dissimilar weld joints between low alloy steel and duplex stainless steel. 19(6):518–524

Suresh Kumar L, Verma SM, Radhakrishna Prasad P, Kiran Kumar P, Siva Shanker T (2011) Experimental investigation for welding aspects of AISI 304 & 316 by Taguchi technique for the process of TIG & MIG welding. Int J Eng Trends Technol 2(2):27–33

Zhu Q, Yu-Cheng L, Xi-Zang C, Wen-Jie R, Ju-Xin YY-M (2011) Microstructure and mechanical properties in TIG welding of CLAM steel. Fusion Eng Des 861:401–411

Lakshminarayanan AK, Balasubramanian V, Elangavan K (2009) Effect of welding processes on tensile properties of AA6061 aluminum alloy joints. Int J Adv Manuf Technol 40:286–296

Kumar A, Sundarrajan S (2009) Effect of welding parameters on mechanical properties and optimization of pulsed TIG welding of Al-Mg-Si alloy. Int J Adv Manuf Technol 42:118–125

Manti R, Dwivedi DK, Agarwal A (2008) Microstructure and hardness of Al-Mg- Si weldments produced by pulse GTA welding. Int J Manuf Technol 36:263–269

Chandramouli R, Kandavel TK, Karthikeyan P (2014) Experimental investigations on welding behaviour sintered and forged Fe-0.3%C-3%Mo low alloy steel. Mater Des 53:645–650

Kandavel TK, Chandramouli R (2010) Experimental investigations on the microstructure and mechanical properties of sinter-forged Cu and Mo-alloyed low alloy steels. Int J Adv Manuf Technol 50:53–59

Taban E, Kaluc E, Tooge A (2009) Hybrid (plasma + gas tungsten arc) weldability of modified 12% Cr ferritic stainless steel. Mater Des 30:4236–4242

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chandramouli, R., Kandavel, T.K. & Karthikeyan, P. Experimental investigations on welding characteristics of sinter-forged pre-alloy Atomet 4601 steel. Int J Adv Manuf Technol 88, 1065–1074 (2017). https://doi.org/10.1007/s00170-016-8825-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8825-8