Abstract

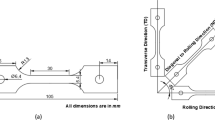

The plastic anisotropy of a ZK60 magnesium alloy sheet was investigated using uniaxial tensile tests and deep drawing tests. The earing behavior of the sheet during deep drawing was studied by both experimental and finite element analyses. The ZK60 alloy sheet exhibits higher plastic strain ratio (r) value in 45° than those in 0° and 90° to rolling direction, and the r value decreases with temperature increasing in various loading directions. A negative planar anisotropy (△r) value results in earing in 45° to rolling direction. Higher absolute value of △r leads to larger average earing ratios. With drawing ratio (DR) increasing, the average earing ratio first increases to a peak and then drops, showing a bell-shape curve. The average earing ratio of cylindrical drawn cup increases as the deep drawing proceeds. At the shoulder region of drawn cups, the most reduction in thickness strain occurs in 45° to rolling direction of the sheet. At the necking region, the minimum thickness strain in 0° is lower than those in 45° and 90° directions. At the thickening region, the minimum thickness strain in 45° is lower than those in 0° and 90° directions due to the large circumferential compression stress and the large negative value of planar anisotropy △r value.

Similar content being viewed by others

References

Li QZ, Tian B (2012) Mechanical properties and microstructure of pure polycrystalline magnesium rolled by different routes. Mater Lett 67:81–83

Kulekci MK (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39:851–865

Agnew SR, Duygulu Ö (2005) Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int J Plast 21:1161–1193

Kleiner S, Uggowitzer PJ (2004) Mechanical anisotropy of extruded Mg-6% Al-1% Zn alloy. Mater Sci Eng A 379:258–263

Song B, Xin RL, Guo N, Xu JB, Sun LY, Liu Q (2015) Dependence of tensile and compressive deformation behavior on aging precipitation in rolled ZK60 alloys. Mater Sci Eng A 639:724–731

Chan LC, Lu XZ (2014) Material sensitivity and formability prediction of warm-forming magnesium alloy sheets with experimental verification. Int J Adv Manuf Technol 71:253–262

Yan H, Chen RS, Han EH (2010) Room-temperature ductility and anisotropy of two rolled Mg-Zn-Gd alloys. Mater Sci Eng A 527:3317–3322

Saxena RK, Dixit PM (2009) Finite element simulation of earing defect in deep drawing. Int J Adv Manuf Technol 45:219–233

Kishor N, Ravi Kumar D (2002) Optimization of initial blank shape to minimize earing in deep drawing using finite element method. J Mater Process Technol 130–131:20–30

Doege E, Seidel M (1988) Influence of anisotropy in sheet metal forming. Model Metal Form Process 123–130

Jung DW, Song IS, Yang DY (1995) An improved method for the application of blank-holding force considering the sheet thickness in the deep-drawing simulation of planar anisotropic sheet. J Mater Process Technol 52:472–488

Ohwue T, Kobayashi Y (2014) Analysis of earing in circular-shell deep-drawing of bcc and hcp sheet metals. Procedia Eng 81:887–892

Yi S, Bohelen J, Heinemann F, Letzig D (2010) Mechanical anisotropy and deep drawing behavior of AZ31 and ZE10 magnesium alloy sheets. Acta Mater 58:592–605

Keeler SP (1968) Understanding sheet metal formability. National Steel Corporation, USA

Leu D-K (1997) Prediction of the limiting drawing ratio and the maximum drawing load in the cup drawing. Int J Mach Tools Manuf 37(2):201–213

Zhang SH, Zhang K, Xu YC, Wang ZT, Xu Y, Wang ZG (2007) Deep-drawing of magnesium alloy sheets at warm temperatures. J Mater Process Technol 185:147–151

Barlat F, Lian J (1989) Plastic behavior and stretch ability of sheet metals. Part I. A yield function for orthotropic sheets under plane stress conditions. Int J Plast 5:51–66

Liu HW, Yao SJ, Liu WL (2007) Forming limit diagram of magnesium alloy ZK60 at elevated temperature. Adv Mater Res 308–310:2442–2445

Lin P, He ZB, Yuan SJ, Shen J (2012) Tensile deformation behavior of Ti-22Al-25Nb alloy at elevated temperatures. Mater Sci Eng A 556(11):617–624

Chino Y, Kimura K, Hakamada M, Mabuchi M (2008) Mechanical anisotropy due to twinning in an extruded AZ31 Mg alloy. Mater Sci Eng A 485:311–317

Gall S, Coelho RS, Müller S, Reimers W (2013) Mechanical properties and forming behavior of extruded AZ31 and ME21 magnesium alloy sheets. Mater Sci Eng A 579:180–187

Hosford WF, Caddell RM (2007) Metal forming: metallurgy and mechanics. Cambridge University Press, Cambridge

Shimizu T, Ogawa M, Yang M, Manabe K (2014) Plastic anisotropy of ultra-thin rolled phosphor bronze foils and its thickness strain evolution in micro-deep drawing. Mater Des 56:604–612

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, P., Sun, Y., Chi, C. et al. Effect of plastic anisotropy of ZK60 magnesium alloy sheet on its forming characteristics during deep drawing process. Int J Adv Manuf Technol 88, 1629–1637 (2017). https://doi.org/10.1007/s00170-016-8816-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8816-9