Abstract

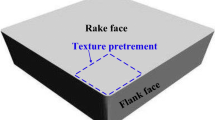

Friction at the tool-chip interface may be reduced by introducing a lubricant into the tool-chip interface; the effectiveness of which can be enhanced by surface texturing the tool. Micro-grooves, micro-pits, and hybrid texture combining micro-pits and micro-grooves were fabricated employing laser on the rake face of carbide tools, with a view to facilitating lubricant penetrate and retention; then, solid lubricant (molybdenum disulfide) was applied to fill micro-textures to form micro-pools. In the present study, the effect of hybrid texture on the cutting performance was experimentally investigated using the hybrid-textured tools, single-textured tools, and conventional tools in dry turning pure iron tests on the numerical control lathe. The behavior of these tools was quantified in terms of the cutting forces, cutting temperature, friction coefficient at the tool-chip interface, shear angle, surface roughness of machined workpiece, chip morphology, and tool wear on the rake face. Results confirm enhanced cutting performance of hybrid-textured tools by collaborative complementation as micro-reservoir for constant lubricant replenishment of micro-grooves and micro-pits. It is suggested that the hybrid-textured self-lubricating tool is applicable to a stable dry cutting of pure iron.

Similar content being viewed by others

References

Shaw MC (2005) Metal cutting principles. New York, USA

Xu DM, Huang M, Xia ZH (2011) Study on the cutting performance of ceramic cutting tool in turning pure iron. Mod Manuf Eng 05:85–88

Xu DM, Chen H, Kong JX (2014) Study on application of lubrication technology in turning pure iron. Mater Sci Forum 770:116–119

Etsion I, Burstein L (1996) A model for mechanical seals with regular micro-surface structure. Tribol Trans 39(3):677–683

Etsion I (2004) Improving tribological performance of mechanical components by laser surface texturing. Tribol Lett 17(4):733–737

Obikawa T, Kamio A, Takaoka H, Osada A (2011) Micro-texture at the coated tool face for high performance cutting. Int J Mach Tools Manuf 51(12):966–972

Sugihara T, Enomoto T (2009) Development of a cutting tool with nano/micro-textured surface: improvement of anti-adhesive effect by considering the texture patterns. Precis Eng 33(4):425–429

Qian S, Zhu D, Qu N, Li H, Yan DS (2010) Generating micro-dimples array on the hard chrome-coated surface by modified through mask electrochemical micromachining. Int J Adv Manuf Technol 47(9–12):1121–1127

Shen XH, Tao GC (2015) Tribological behaviors of two micro textured surfaces generated by vibrating milling under boundary lubricated sliding. Int J Adv Manuf Technol: 1–8

Sugihara T, Enomoto T (2012) Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis Eng 36(2):229–237

Evans CJ, Bryan JB (1999) “Structured” “textured” or “engineered” surfaces. CIRP Ann Manuf Technol 48(2):541–556

Machado AR, Wallbank J (1994) The effects of a high-pressure coolant jet on machining. Proc Inst Mech Eng B J Eng Manuf 208(1):29–38

Hong SY, Ding Y, Jeong J (2002) Experimental evaluation of friction coefficient and liquid nitrogen lubrication effect in cryogenic machining. Mach Sci Technol 6(2):235–250

Dumitru G, Romano V, Gerbig Y, Weber HP, Haefke H (2005) Femtosecond laser processing of nitride-based thin films to improve their tribological performance. Appl Phys A 80(2):283–287

Wei W, Lankford J, Kossowsky R (1987) Friction and wear of ion-beam-modified ceramics for use in high temperature adiabatic engines. Mater Sci Eng 90:307–315

Julthongpiput D, Ahn HS, Sidorenko A, Kim DI, Tsukruk VV (2002) Towards self-lubricated nanocoatings. Tribol Int 35(12):829–836

Deng JX, Ding ZL, Zhao J, Wang JH, Ai X (2003) Development of the high-temperature self-lubricating ceramic tool materials and its cutting performance. Chin J Mech Eng 39(8):106–109

Deng JX, Ge PQ, Ai X (2003) Development and perspective of lubricating techniques in metal cutting. Tribology 23:546–550

Segu DZ, Choi SG, Hyouk Choi J, Kim SS (2013) The effect of multi-scale laser textured surface on lubrication regime. Appl Surf Sci 270:58–63

Ruan HY, Lu JJ (2010) Hydrodynamic lubrication performance on multi-textured surface structured by multi-arcs and triangle textures. J Jiangsu Univ (Nat Sci Edn) 3, 003

Yin BF, Qian AQ, Lu ZT, Wang BW, Sun A (2014) Theoretical and experimental study on lubrication performance of composite textures on cylinder liners. J Xian Jiaotong Univ 48(9):74–80

Chen RY (2000) Metal cutting principles. Beijing, China

Tian WS, Le DQ (1990) The study of cutting performance of pure iron. J Taiyuan Heavy Mach Inst 2:002

Kong JX, Li L, Xu DM, He N (2014) Study on tool life and tool wear mechanisms in dry cutting pure iron. Mater Sci Forum 770:74–77

Lei ST, Devarajan S, Chang ZH (2009) A comparative study on the machining performance of textured cutting tools with lubrication. Int J Mech Manuf Syst 2(4):401–413

Marinov VR (2001) Hybrid analytical–numerical solution for the shear angle in orthogonal metal cutting—part I: theoretical foundation. Int J Mech Sci 43(2):399–414

Recht RF (1985) A dynamic analysis of high-speed machining. J Manuf Sci Eng 107(4):309–315

Erdemir A (2005) Review of engineered tribological interfaces for improved boundary lubrication. Tribol Int 38(3):249–256

Cordier-Robert C, Crampon J, Foct J (1998) Surface alloying of iron by laser melting: microstructure and mechanical properties. Surf Eng 14(5):381–385

De Damborenea J (1998) Surface modification of metals by high power lasers. Surf Coat Technol 100:377–382

Fu H, Chen YJ (1998) Research on the principle of cutting process of cutters with friction-decreasing grooves. Tool Eng 32(2):7–10

Lei ST, Devarajan S, Chang ZH (2009) A study of micro-pool lubricated cutting tool in machining of mild steel. J Mater Process Technol 209(3):1612–1620

Kim DM, Bajpai V, Kim BH, Park HW (2015) Finite element modeling of hard turning process via a micro-textured tool. Int J Adv Manuf Technol 78(9–12):1393–1405

Wang YH (1996) Alloy cast iron cutting principles. Jiang Su, China

Sun JL, Zhou YH, Deng JX (2015) Research on textured coating tool. Tool Eng 7:002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, J., Zhou, Y., Deng, J. et al. Effect of hybrid texture combining micro-pits and micro-grooves on cutting performance of WC/Co-based tools. Int J Adv Manuf Technol 86, 3383–3394 (2016). https://doi.org/10.1007/s00170-016-8452-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8452-4