Abstract

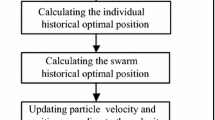

A variety of manufacturing operations together with a variety of alternative manufacturing resources provide that most jobs in the modern manufacturing systems may have a large number of alternative process plans. For that reason, obtaining an optimal process plan according to all alternative manufacturing resources (machine tools, cutting tools, tool access directions, etc.) as well as alternative operations has become a very important task in flexible process planning problem research. In this paper, we present and evaluate a new algorithm for optimization of flexible process plans based on utilization of particle swarm optimization (PSO) algorithm and chaos theory. The main idea is to prevent the convergence of PSO in early stages of optimization process by implementing ten different chaotic maps which enlarge search space and provide its diversity. The flexible process plans are represented by using AND/OR network, and machine flexibility, tool flexibility, tool access direction (TAD) flexibility, process flexibility and sequence flexibility are considered. Further, mathematical models for minimization of production time and total production cost are derived. The newly developed algorithm is extensively experimentally verified by using four experimental studies, which show that the developed method outperforms genetic algorithm (GA), simulated annealing (SA), hybrid GA-SA and generic PSO based approach.

Similar content being viewed by others

References

Yusof Y, Latif K (2014) Survey on computer-aided process planning. Int J Adv Manuf Technol 75(1–4):77–89

Zhang F, Zhang YF, Nee AYC (1997) Using genetic algorithms in process planning for job shop machining. Evol Comput IEEE Trans 1(4):278–289

Reddy SVB, Shunmugam MS, Narendran TT (1999) Operation sequencing in CAPP using genetic algorithms. Int J Prod Res 37(5):1063–1074

Salehi M, Tavakkoli-Moghaddam R (2009) Application of genetic algorithm to computer-aided process planning in preliminary and detailed planning. Eng Appl Artif Intell 22(8):1179–1187

Su Y, Chu X, Chen D, Sun X (2015) A genetic algorithm for operation sequencing in CAPP using edge selection based encoding strategy. Journal of Intelligent Manufacturing, 1–20. DOI 10.1007/s10845-015-1109-6

Ma GH, Zhang YF, Nee A (2000) A simulated annealing based optimization algorithm for process planning. Int J Prod Res 38(12):2671–2687

Nallakumarasamy G, Srinivasan PSS, Raja KV, Malayalamurthi R (2011) Optimization of operation sequencing in CAPP using simulated annealing technique (SAT). Int J Adv Manuf Technol 54(5–8):721–728

Li WD, Ong SK, Nee AYC (2004) Optimization of process plans using a constraint-based tabu search approach. Int J Prod Res 42(10):1955–1985

Krishna AG, Rao KM (2006) Optimisation of operations sequence in CAPP using an ant colony algorithm. Int J Adv Manuf Technol 29(1–2):159–164

Liu XJ, Yi H, Ni ZH (2013) Application of ant colony optimization algorithm in process planning optimization. J Intell Manuf 24(1):1–13

Wang J, Wu X, Fan X (2015) A two-stage ant colony optimization approach based on a directed graph for process planning. The International Journal of Advanced Manufacturing Technology, 1–12

Guo YW, Mileham AR, Owen GW, Li WD (2006) Operation sequencing optimization using a particle swarm optimization approach. Proc Inst Mech Eng B J Eng Manuf 220(12):1945–1958

Wen XY, Li XY, Gao L, Sang HY (2014) Honey bees mating optimization algorithm for process planning problem. J Intell Manuf 25(3):459–472

Lian K, Zhang C, Shao X, Gao L (2012) Optimization of process planning with various flexibilities using an imperialist competitive algorithm. Int J Adv Manuf Technol 59(5–8):815–828

Li WD, Ong SK, Nee A (2002) Hybrid genetic algorithm and simulated annealing approach for the optimization of process plans for prismatic parts. Int J Prod Res 40(8):1899–1922

Xu L, Deng W, Liu W, Ma S, Li A, Matta A (2014) Optimization of process planning for cylinder block based on feature machining elements. In: Proceedings of the IEEE International Conference on Systems, Man and Cybernetics (SMC), San Diego, USA, pp. 2575–2580

Salehi M, Bahreininejad A (2011) Optimization process planning using hybrid genetic algorithm and intelligent search for job shop machining. J Intell Manuf 22(4):643–652

Su Y, Chu X, Zhang Z, Chen D (2015) Process planning optimization on turning machine tool using a hybrid genetic algorithm with local search approach. Advances in Mechanical Engineering, 7(4), DOI: 10.1177/1687814015581241

Wang YF, Zhang YF, Fuh JYH (2012) A hybrid particle swarm based method for process planning optimisation. Int J Prod Res 50(1):277–292

Zhang HC, Huang SH (1994) A fuzzy approach to process plan selection. Int J Prod Res 32(6):1265–1279

Li XY, Shao XY, Gao L (2008) Optimization of flexible process planning by genetic programming. Int J Adv Manuf Technol 38(1–2):143–153

Shao X, Li X, Gao L, Zhang C (2009) Integration of process planning and scheduling—a modified genetic algorithm-based approach. Comput Oper Res 36(6):2082–2096

Lv S, Qiao L (2013) A cross-entropy-based approach for the optimization of flexible process planning. Int J Adv Manuf Technol 68(9–12):2099–2110

Petrović M, Miljković Z, Babić B (2012) Optimization of operation sequencing in CAPP using hybrid genetic algorithm and simulated annealing approach, In: Proceedings of the 11th International Scientific Conference MMA 2012—Advanced Production Technologies, Novi Sad, Serbia, pp. 285–288

Wang Y, Liu JH (2010) Chaotic particle swarm optimization for assembly sequence planning. Robot Comput Integr Manuf 26(2):212–222

Liu B, Wang L, Jin YH, Tang F, Huang DX (2005) Improved particle swarm optimization combined with chaos. Chaos, Solitons Fractals 25(5):1261–1271

Xiang T, Liao X, Wong KW (2007) An improved particle swarm optimization algorithm combined with piecewise linear chaotic map. Appl Math Comput 190(2):1637–1645

Alatas B, Akin E (2009) Chaotically encoded particle swarm optimization algorithm and its applications. Chaos, Solitons Fractals 41(2):939–950

Gandomi AH, Yun GJ, Yang XS, Talatahari S (2013) Chaos-enhanced accelerated particle swarm optimization. Commun Nonlinear Sci Numer Simul 18(2):327–340

Lin GYJ, Solberg JJ (1991) Effectiveness of flexible routing control. Int J Flex Manuf Syst 3(3–4):189–211

Browne J, Dubois D, Rathmill K, Sethi SP, Stecke KE (1984) Classification of flexible manufacturing systems. FMS Mag 2(2):114–117

Chryssolouris G (2005) Manufacturing systems: theory and practice. Springer

Li X, Gao L, Wen X (2013) Application of an efficient modified particle swarm optimization algorithm for process planning. Int J Adv Manuf Technol 67(5–8):1355–1369

Kalajdžić M (2006) Manufacturing technology, Faculty of Mechanical Engineering, Belgrade

Huang W, Hu Y, Cai L (2012) An effective hybrid graph and genetic algorithm approach to process planning optimization for prismatic parts. Int J Adv Manuf Technol 62(9–12):1219–1232

Kennedy J, Eberhart RC (1995) Particle swarm optimization. In: Proceedings of the IEEE International Conference on Neural Network, Perth, Australia, pp. 1942–1948

Kennedy J (1997) The particle swarm: social adaptation of knowledge. In: Proceedings of the IEEE International Conference on Evolutionary Computation, Indianapolis, USA, pp. 303–308

Shin KS, Park JO, Kim YK (2010) Test-bed problems for multi-objective FMS process planning using multi-objective symbiotic evolutionary algorithm. http://syslab.chonnam.ac.kr/links/MO_FMS_PP_MOSEA.doc

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Petrović, M., Mitić, M., Vuković, N. et al. Chaotic particle swarm optimization algorithm for flexible process planning. Int J Adv Manuf Technol 85, 2535–2555 (2016). https://doi.org/10.1007/s00170-015-7991-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7991-4