Abstract

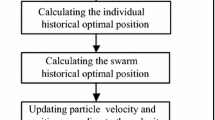

In the modern manufacturing system, many flexible manufacturing system and NC machines are introduced to improve the production efficiency. Therefore, most parts have a large number of flexible process plans. However, a part can use only one process plan in the manufacturing process. So, the process planning problem has become a crucial problem in the manufacturing environment. It is a combinatorial optimization problem to conduct operations selection and operations sequencing simultaneously with various constraints deriving from the practical workshop environment as well as the parts to be processed. It is a NP-hard problem. In order to solve this problem effectively, this paper proposes a novel modified particle swarm optimization (PSO) algorithm to optimize the process planning problem. To improve the performance of the approach, efficient encoding, updating, and random search methods have been developed. To verify the feasibility and effectiveness of the proposed approach, seven cases have been conducted. The proposed algorithm has also been compared with the genetic algorithm and simulated annealing algorithm. The results show that the proposed modified PSO algorithm can generate satisfactory solutions and outperform other algorithms.

Similar content being viewed by others

References

Han JH, Han I, Lee E, Yi J (2001) Manufacturing feature recognition toward integration with process planning. IEEE Trans Syst Man Cybern B Cybern 31:373–380

Xu X, Wang LH, Newman ST (2011) Computer-aided process planning—a critical review of recent developments and future trends. Int J Comput Integr Manuf 24(1):1–31

Liu XJ, Yi H, Ni ZH (2010) Application of ant colony optimization algorithm in process planning optimization. J Intell Manuf, doi: 10.1007/s10845-010-0407-2

Kusiak A (1985) Integer programming approach to process planning. Int J Adv Manuf Technol 1:73–83

Gan PY, Lee KS, Zhang YF (2001) A branch and bound algorithm based process-planning system for plastic injection mould bases. Int J Adv Manuf Technol 18:624–632

Xu HM, Li DB (2008) A clustering based modeling schema of the manufacturing resources for process planning. Int J Adv Manuf Technol 38:154–162

Xu HM, Yuan MH, Li DB (2009) A novel process planning schema based on process knowledge customization. Int J Adv Manuf Technol 44:161–172

Zhang J, Gao L, Chan FTS, Li PG (2003) A holonic architecture of the concurrent integrated process planning system. J Mater Process Technol 139:267–272

Nejad HTN, Sugimura N, Iwamura K, Tanimizu Y (2010) Multi-agent architecture for dynamic incremental process planning in the flexible manufacturing system. J Intell Manuf 21:487–499

Dashora Y, Tiwari MK, Karunakaran KP (2008) A psycho-clonal-algorithm-based approach to the solve operation sequencing problem in a CAPP environment. Int J Comput Integr Manuf 21:510–525

Chan FTS, Swarnkar R, Tiwari MK (2005) Fuzzy goal-programming model with an artificial immune system (AIS) approach for a machine tool selection and operation allocation problem in a flexible manufacturing system. Int J Prod Res 43:4147–4163

Houshmand M, Imani DM, Niaki STA (2009) Using flower pollinating with artificial bees (FPAB) technique to determine machinable volumes in process planning for prismatic parts. Int J Adv Manuf Technol 45:944–957

Shin KS, Park JO, Kim YK (2011) Multi-objective FMS process planning with various flexibilities using a symbiotic evolutionary algorithm. Comput Oper Res 38:702–712

Li XY, Shao XY, Gao L (2008) Optimization of flexible process planning by genetic programming. Int J Adv Manuf Technol 38:143–153

Li WD, Ong SK, Nee AYC (2004) Optimization of process plans using a constraint-based tabu search approach. Int J Prod Res 42:1955–1985

Lian KL, Zhang CY, Shao XY, Zeng YH (2011) A multi-dimensional tabu search for the optimization of process planning. Sci China Ser E Technol Sci 54:3211–3219

Lian KL, Zhang CY, Shao XY, Gao L (2012) Optimization of process planning with various flexibilities using an imperialist competitive algorithm. Int J Adv Manuf Technol 59:815–828

Zhang F, Zhang YF, Nee AYC (1997) Using genetic algorithms in process planning for job shop machining. IEEE Trans Evol Comput 1:278–289

Li L, Fuh JYH, Zhang YF, Nee AYC (2005) Application of genetic algorithm to computer-aided process planning in distributed manufacturing environments. Robot Comput Integr Manuf 21:568–578

Hua GR, Zhou XH, Ruan XY (2007) GA-based synthesis approach for machining scheme selection and operation sequencing optimization for prismatic parts. Int J Adv Manuf Technol 33:594–603

Salehi M, Tavakkoli Moghaddam R (2009) Application of genetic algorithm to computer-aided process planning in preliminary and detailed planning. Eng Appl Artif Intell 22:1179–1187

Musharavati F, Hamouda ASM (2011) Modified genetic algorithms for manufacturing process planning in multiple parts manufacturing lines. Expert Syst Appl 38:10770–10779

Salehi M, Bahreininejad A (2011) Optimization process planning using hybrid genetic algorithm and intelligent search for job shop machining. J Intell Manuf 22:643–652

Krishna AG, Mallikarjuna Rao K (2006) Optimisation of operations sequence in CAPP using an ant colony algorithm. Int J Adv Manuf Technol 29:159–164

Tiwari MK, Dashora Y, Kumar S, Shankar R (2006) Ant colony optimization to select the best process plan in an automated manufacturing environment. Proc IMechE B J Eng Manuf 220:1457–1472

Ma GH, Zhang YF, Nee AYC (2000) A simulated annealing-based optimization algorithm for process planning. Int J Prod Res 38:2671–2687

Mishra S, Prakash Tiwari MK, Lashkari RS (2006) A fuzzy goal-programming model of machine-tool selection and operation allocation problem in FMS: a quick converging simulated annealing-based approach. Int J Prod Res 44:43–76

Musharavati F, Hamouda ASM (2012) Enhanced simulated annealing based algorithms and their applications to process planning in reconfigurable manufacturing systems. Adv Eng Softw 45:80–90

Musharavati F, Hamouda AMS (2012) Simulated annealing with auxiliary knowledge for process planning optimization in reconfigurable manufacturing. Robot Comput Integr Manuf 28:113–131

Li WD, Ong SK, Nee AYC (2005) A Web-based process planning optimization system for distributed design. Comput Aided Des 37:921–930

Li WD (2005) A Web-based service for distributed process planning optimization. Comput Ind 56:272–288

Ming XG, Mak KL (2000) A hybrid Hopfield network-genetic algorithm approach to optimal process plan selection. Int J Prod Res 38:1823–1839

Zhang F, Nee AYC (2001) Applications of genetic algorithms and simulated annealing in process planning optimization. In: Wang J, Kusiak A (eds) Computational intelligence in manufacturing handbook. CRC, Boca Raton, pp 9.1–9.26

Li WD, Ong SK, Nee AYC (2002) Hybrid genetic algorithm and simulated annealing approach for the optimization of process plans for prismatic parts. Int J Prod Res 40:1899–1922

Huang WJ, Hu YJ, Cai LG (2012) An effective hybrid graph and genetic algorithm approach to process planning optimization for prismatic parts. Int J Adv Manuf Technol 62:1219–1232

Ali MM, Kaelo P (2008) Improved particle swarm algorithms for global optimization. Appl Math Comput 196:578–593

Goh CK, Tan KC, Liu DS, Chiam SC (2010) A competitive and cooperative co-evolutionary approach to multi-objective particle swarm optimization algorithm design. Eur J Oper Res 202:42–54

Shi Y, Liu H, Gao L, Zhang G (2011) Cellular particle swarm optimization. Inf Sci 181:4460–4493

Wang TI, Tsai KH (2009) Interactive and dynamic review course composition system utilizing contextual semantic expansion and discrete particle swarm optimization. Expert Syst Appl 36:9663–9673

Wang Y, Liu JH (2010) Chaotic particle swarm optimization for assembly sequence planning. Robot Comput Integr Manuf 26:212–222

Moslehi G, Mahnam M (2011) A Pareto approach to multi-objective flexible job-shop scheduling problem using particle swarm optimization and local search. Int J Prod Econ 129:14–22

Zhang WB, Zhu GY (2011) Comparison and application of four versions of particle swarm optimization algorithms in the sequence optimization. Expert Syst Appl 38:8858–8864

Chen SM, Chien CY (2011) Solving the traveling salesman problem based on the genetic simulated annealing ant colony system with particle swarm optimization techniques. Expert Syst Appl 38:14439–14450

Guo YW, Mileham AR, Owen GW, Li WD (2006) Operation sequencing optimization using a particle swarm optimization approach. Proc IMechE B J Eng Manuf 220:1945–1958

Wang YF, Zhang YF, Fuh JYH (2009) Using hybrid particle swarm optimization for process planning problem. In: 2009 International Joint Conference on Computational Sciences and Optimization, 304–308

Eberhart RC, Shi Y (2004) Guest editorial: special issue on particle swarm optimization. IEEE Trans Evol Comput 8(3):201–203

Gao L, Peng CY, Zhou C, Li PG (2006) Solving flexible job shop scheduling problem using general particle swarm optimization. In: Proceeding of the 36th International Conference on Computers & Industrial Engineering, 3018–3027

Li WD, McMahon CA (2007) A simulated annealing based optimization approach for integrated process planning and scheduling. Int J Comput Integr Manuf 20(1):80–95

Kim YK, Park K, Ko J (2003) A symbiotic evolutionary algorithm for the integration of process planning and job shop scheduling. Comput Oper Res 30:1151–1171

Kim YK (2003) A set of data for the integration of process planning and job shop scheduling. Available at http://syslab.chonnam.ac.kr/links/data-pp&s.doc. April 2011

Shin KS, Park JO, Kim YK (2010) Test-bed problems for multi-objective FMS process planning using multi-objective symbiotic evolutionary algorithm. Available at http://syslab.chonnam.ac.kr/links/MO_FMS_PP_MOSEA.doc. March 2011

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Gao, L. & Wen, X. Application of an efficient modified particle swarm optimization algorithm for process planning. Int J Adv Manuf Technol 67, 1355–1369 (2013). https://doi.org/10.1007/s00170-012-4572-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4572-7