Abstract

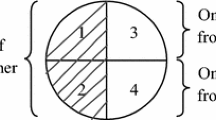

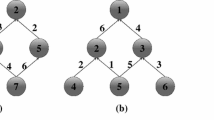

Process planning and scheduling are two of the most important functions of a manufacturing system. Traditionally, these two functions are executed separately. Since they are interrelated, conducting process planning and scheduling simultaneously will provide more advantages. In this paper, according to the characteristics of the integrated process planning and scheduling (IPPS) problem, a hybrid honey bee mating optimization (HBMO) algorithm, which combines the HBMO algorithm and variable neighborhood search (VNS), is proposed to settle the problem with makespan criterion. Different with conventional HBMO, we utilize VNS with two effective and efficient neighborhood structures in the algorithm to simulate the workers’ brood caring action to avoid premature convergence and to find more excellent broods. In addition, a novel individual initialization method is developed in the algorithm. The proposed algorithm is tested on typical benchmark instances taken from related literature, and the computational results are compared with those of other algorithms. Experimental results show the effectiveness and efficiency of the hybrid HBMO algorithm. New upper bounds have been captured for 16 instances, and most instances have been improved within reasonable CPU times.

Similar content being viewed by others

References

Lian KL, Zhang CY, Shao XY, Gao L (2012) Optimization of process planning with various flexibilities using an imperialist competitive algorithm. Int J Adv Manuf Technol 59(5–8):815–828. doi:10.1007/s00170-011-3527-8

Li X, Gao L, Wen X (2013) Application of an efficient modified particle swarm optimization algorithm for process planning. Int J Adv Manuf Technol 67(5–8):1355–1369. doi:10.1007/s00170-012-4572-7

Lv S, Qiao L (2013) A cross-entropy-based approach for the optimization of flexible process planning. Int J Adv Manuf Technol 68(9–12):2099–2110. doi:10.1007/s00170-013-4815-2

Lian KL, Zhang CY, Gao L, Li XY (2012) Integrated process planning and scheduling using an imperialist competitive algorithm. Int J Prod Res 50(15):4326–4343. doi:10.1080/00207543.2011.622310

Li XY, Shao XY, Gao L, Qian WR (2010) An effective hybrid algorithm for integrated process planning and scheduling. Int J Prod Econ 126(2):289–298. doi:10.1016/j.ijpe.2010.04.001

Kim YK, Park K, Ko J (2003) A symbiotic evolutionary algorithm for the integration of process planning and job shop scheduling. Comput Oper Res 30(8):1151–1171. doi:10.1016/s0305-0548(02)00063-1

Kumar M, Rajotia S (2006) Integration of process planning and scheduling in a job shop environment. Int J Adv Manuf Technol 28(1–2):109–116. doi:10.1007/s00170-004-2317-y

Saygin C, Kilic SE (1999) Integrating flexible process plans with scheduling in flexible manufacturing systems. Int J Adv Manuf Technol 15(4):268–280. doi:10.1007/s001700050066

Lee H, Kim SS (2001) Integration of process planning and scheduling using simulation based genetic algorithms. Int J Adv Manuf Technol 18(8):586–590. doi:10.1007/s001700170035

Tan W, Khoshnevis B (2004) A linearized polynomial mixed integer programming model for the integration of process planning and scheduling. J Intell Manuf 15(5):593–605. doi:10.1023/B:JIMS.0000037710.80847.b6

Shukla SK, Tiwari MK, Son YJ (2008) Bidding-based multi-agent system for integrated process planning and scheduling: a data-mining and hybrid tabu-SA algorithm-oriented approach. Int J Adv Manuf Technol 38(1–2):163–175. doi:10.1007/s00170-007-1087-8

Fathian M, Amiri B, Maroosi A (2007) Application of honey-bee mating optimization algorithm on clustering. Appl Math Comput 190(2):1502–1513. doi:10.1016/j.amc.2007.02.029

Özgüven C, Özbakır L, Yavuz Y (2010) Mathematical models for job-shop scheduling problems with routing and process plan flexibility. Appl Math Model 34(6):1539–1548. doi:10.1016/j.apm.2009.09.002

Doh H-H, Yu J-M, Kim J-S, Lee D-H, Nam S-H (2013) A priority scheduling approach for flexible job shops with multiple process plans. Int J Prod Res 51(12):3748–3764. doi:10.1080/00207543.2013.765074

Wang YF, Zhang Y, Fuh JYH (2011) Job rescheduling by exploring the solution space of process planning for machine breakdown/arrival problems. Proc Inst Mech Eng B J Eng 225(2):282–296. doi:10.1243/09544054jem1951

Li XY, Gao L, Shao XY (2012) An active learning genetic algorithm for integrated process planning and scheduling. Expert Syst Appl 39(8):6683–6691. doi:10.1016/j.eswa.2011.11.074

Guo YW, Li WD, Mileham AR, Owen GW (2009) Optimisation of integrated process planning and scheduling using a particle swarm optimisation approach. Int J Prod Res 47(14):3775–3796. doi:10.1080/00207540701827905

Haddadzade M, Razfar MR, Zarandi MHF (2014) Integration of process planning and job shop scheduling with stochastic processing time. Int J Adv Manuf Technol 71(1–4):241–252. doi:10.1007/s00170-013-5469-9

Marinaki M, Marinakis Y, Zopounidis C (2010) Honey bees mating optimization algorithm for financial classification problems. Appl Soft Comput 10(3):806–812. doi:10.1016/j.asoc.2009.09.010

Kang Q-M, He H, Song H-M, Deng R (2010) Task allocation for maximizing reliability of distributed computing systems using honeybee mating optimization. J Syst Softw 83(11):2165–2174. doi:10.1016/j.jss.2010.06.024

Niknam T (2011) An efficient multi-objective HBMO algorithm for distribution feeder reconfiguration. Expert Syst Appl 38(3):2878–2887. doi:10.1016/j.eswa.2010.08.081

Guo YW, Li WD, Mileham AR, Owen GW (2009) Applications of particle swarm optimisation in integrated process planning and scheduling. Robot Comput Integr Manuf 25(2):280–288. doi:10.1016/j.rcim.2007.12.002

Li XY, Shao XY, Gao L (2008) Optimization of flexible process planning by genetic programming. Int J Adv Manuf Technol 38(1–2):143–153. doi:10.1007/s00170-007-1069-x

Afshar A, Bozorg Haddad O, Mariño MA, Adams BJ (2007) Honey-bee mating optimization (HBMO) algorithm for optimal reservoir operation. J Franklin Inst 344(5):452–462. doi:10.1016/j.jfranklin.2006.06.001

Bierwirth C (1995) A generalized permutation approach to job shop scheduling with genetic algorithms. OR Spectrum 17(2–3):87–92

Tseng HE (2006) Guided genetic algorithms for solving a larger constraint assembly problem. Int J Prod Res 44(3):601–625. doi:10.1080/00207540500270513

Bierwirth C, Mattfeld DC (1999) Production scheduling and rescheduling with genetic algorithms. Evol Comput 7(1):1–17. doi:10.1162/evco.1999.7.1.1

Nowicki E, Smutnicki C (1996) A fast taboo search algorithm for the job shop problem. Manag Sci 42(6):797–813. doi:10.1287/mnsc.42.6.797

Gao J, Sun L, Gen M (2008) A hybrid genetic and variable neighborhood descent algorithm for flexible job shop scheduling problems. Comput Oper Res 35(9):2892–2907. doi:10.1016/j.cor.2007.01.001

Meenakshi Sundaram R, S-s F (1988) Process planning and scheduling—a method of integration for productivity improvement. Comput Ind Eng 15(1–4):296–301. doi:10.1016/0360-8352(88)90102-7

Morad N, Zalzala A (1999) Genetic algorithms in integrated process planning and scheduling. J Intell Manuf 10(2):169–179. doi:10.1023/a:1008976720878

Li XY, Gao L, Shao XY, Zhang CY, Wang CY (2010) Mathematical modeling and evolutionary algorithm-based approach for integrated process planning and scheduling. Comput Oper Res 37(4):656–667. doi:10.1016/j.cor.2009.06.008

Jain A, Jain PK, Singh IP (2006) An integrated scheme for process planning and scheduling in FMS. Int J Adv Manuf Technol 30(11–12):1111–1118. doi:10.1007/s00170-005-0142-6

Lihong Q, Shengping L (2012) An improved genetic algorithm for integrated process planning and scheduling. Int J Adv Manuf Technol 58(5–8):727–740. doi:10.1007/s00170-011-3409-0

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, L., Zhang, C. & Shao, X. An effective hybrid honey bee mating optimization algorithm for integrated process planning and scheduling problems. Int J Adv Manuf Technol 80, 1253–1264 (2015). https://doi.org/10.1007/s00170-015-7069-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7069-3