Abstract

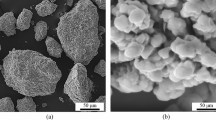

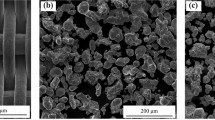

The goal of this study was to propose a new method to fabricate metal/alloy micro-composites and investigate the properties of the micro-composites. A micro-ultrasonic powder moulding method was proposed for the fabrication of copper wires/Sn–Bi eutectic alloy micro-composite (x-Cuw/Sn–Bi, where x refers to the number of copper wires). Micro-structures and tensile properties of the micro-composite were investigated by scanning electron microscopy, energy-dispersive X-ray spectroscopy, X-ray diffraction and tensile tests. Micro-structures indicated that the interface bonding of the copper wires and Sn–Bi alloy matrix was fairly good. During the tensile tests, the micro-composite’s tensile strength increased significantly with increasing the number of copper wires; however, the elongation first improved and then decreased. The reinforced copper wires failed by two mechanisms during the tensile tests. In one mechanism, the copper wire fractured in the middle position, while in the other, it pulled out from the Sn–Bi alloy matrix.

Similar content being viewed by others

References

Purohit R, Sagar R (2010) Fabricaton and testing of Al-SiCp composite poppet valve guides. Int J Adv Manuf Technol 51:685–698

Xu JC, Yu H, Xia L, Li XL, Yang H (2004) Effects of some factors on the tribological properties of the short carbon fiber-reinforced copper composite. Mater Des 25(6):489–493

Jiang L, Li ZQ, Fan GL, Gao LL, Zhang D (2012) The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 50(5):1993–1998

Mazahery A, Shanani MO (2014) The performance of pressure assisted casting process to improve the mechanical properties of Al-Si-Mg alloys matrix reinforced with coated B4C particles. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6266-9

Sample RJ, Bhagat RB, Amateau MF (1989) High pressure squeeze casting of unidirectional graphite fiber reinforced aluminum matrix composites. J Compos Mater 23(10):1021–1028

Liu ZG, Mang XB, Chai LH, Chen YY (2010) Interface study of carbon fibre reinforced Al–Cu composites. J Alloys Compd 504:S512–S514

Daoud A (2005) Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration. Mater Sci Eng A 391(1):114–120

Altunpak Y, Akbulut H (2009) Effects of aging heat treatment on machinability of alumina short fiber reinforced LM 13 aluminum alloy. Int J Adv Manuf Technol 43:449–454

Tang YP, Liu HZ, Zhao HJ, Liu L, Wu YT (2008) Friction and wear properties of copper matrix composites reinforced with short carbon fibers. Mater Des 29(1):257–261

Hajjari E, Divandari M, Mirhabibi AR (2010) The effect of applied pressure on fracture surface and tensile properties of nickel coated continuous carbon fiber reinforced aluminum composites fabricated by squeeze casting. Mater Des 31(5):2381–2386

Vijian P, Arunachalam VP (2007) Optimization of squeeze casting process parameters using Taguchi analysis. Int J Adv Manuf Technol 33:1122–1127

Hufenbach W, Ullrich H, Gude M, Czulak A, Malczyk P, Geske V (2012) Manufacture studies and impact behaviour of light metal matrix composites reinforced by steel wires. Arch Civil Mech Eng 12(3):265–272

Fei JJ, Wang WM, Ren AC, Ji Y, Zhou JH, Zhu M (2014) Mechanical properties and densification of short carbon fiber-reinforced TiB2/C composites produced by hot pressing. J Alloys Compd 584:87–92

Khoddamzadeh A, Liu R, Liang M, Yang Q (2014) Wear resistant carbon fiber reinforced Stellite alloy composites. Mater Des 56:487–494

Yang QR, Liu JX, Li SK, Wang FC, Wu TT (2014) Fabrication and mechanical properties of Cu-coatedwoven carbon fibers reinforced aluminum alloy composite. Mater Des 57:442–448

Zeng K, Wu XY, Liang X, Xu B, Wang YT, Chen XQ, Cheng R, Luo F (2014) Process and properties of micro-ultrasonic powder molding with polypropylene. Int J Adv Manuf Technol 70:515–522

Wu SY, Wu XY, Xu B, Cheng R, Luo F, Ruan SC (2014) A micro-ultrasonic powder moulding method to fabricate Sn–Bi alloy micro parts. J Mater Process Technol 214:2668–2675

Zou HF, Zhang QK, Zhang ZF (2012) Interfacial microstructure and mechanical properties of SnBi/Cu joints by alloying Cu substrate. Mater Sci Eng A 532:167–177

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, Sy., Wu, Xy., Xu, B. et al. Micro-structures and tensile properties of copper-wire-reinforced Sn–Bi alloy micro-composite fabricated by micro-ultrasonic powder moulding. Int J Adv Manuf Technol 79, 897–904 (2015). https://doi.org/10.1007/s00170-015-6859-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-6859-y