Abstract

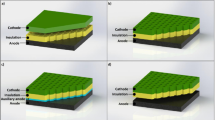

A process to fabricate large-scale three-dimensional microstructures for cylindrical objects is developed by employing the techniques of pre-treatment, coating, rolling exposure, and electrochemical micromachining (EMM). In this work, the rolling exposure technique is advanced and used to fabricate a patterned photoresist mask. Several experiments are implemented to understand the dependence of the microtexture morphology on the EMM process. The various electrochemical mechanisms involved in the EMM process are discussed in detail. Furthermore, the texture surfaces are introduced into a rotor-bearing system and demonstrated a 64 % reduction in the vibrations, improving the stability for the first time. The results of the present study demonstrate the feasibility of using through-mask EMM for producing high-precision topographies on cylindrical objects, and that the application of surface textures in the rotor-bearing system is practical. The technique developed in this study is expected to lead to enhancements in roll-based manufacturing and automotive tribology.

Similar content being viewed by others

References

Kligerman Y, Etsion I (2001) Analysis of the hydrodynamic effects in a surface textured circumferential gas seal. Tribol Trans 44(3):472–478

Vilhena LM, Sedlacek M, Podgornik B, Vizintin J, Babnik A, Mozina J (2009) Surface texturing by pulsed Nd: YAG laser. Tribol Int 42(10):1496–1504

Byun JW, Shin HS, Kwon MH, Kim BH, Chu CN (2010) Surface texturing by micro ECM for friction reduction. Int J Precis Eng Manuf 11(5):747–753

Choi JH, Kim GM (2011) Micro-patterning on non-planar surface using flexible microstencil. Int J Precis Eng Manuf 12(1):165–168

Kim JG, Takama N, Kim BJ, Fujita H (2009) Optical-soft lithographic technology for patterning on curved surfaces. J Micromech Microeng 19(5):8, 055017

Gupta MC, Li B, Gadag S, Chou KC (2010) Laser micromachining for fatigue and fracture mechanics applications. Opt Lasers Eng 48(4):441–447

Zeman R, Bleicher F, Zisser-Pfeifer R (2012) Some practical contributions of the technology of electrochemical micromachining with ultra short pulses. Galvanotechnik 103(4):722–5

Marcinkevicius A, Juodkazis S, Watanabe M, Miwa M, Matsuo S, Misawa H, Nishii J (2001) Femtosecond laser-assisted three-dimensional microfabrication in silica. Opt Lett 26(5):277–279

Gattass RR, Mazur E (2008) Femtosecond laser micromachining in transparent materials. Nat Photonics 2(4):219–225

Li X, Bohn PW (2000) Metal-assisted chemical etching in HF/H(2)O(2) produces porous silicon. Appl Phys Lett 77(16):2572–2574

Moszner N, Salz U, Zimmermann J (2005) Chemical aspects of self-etching enamel-dentin adhesives: a systematic review. Dent Mater 21(10):895–910

Qian BT, Shen ZQ (2005) Fabrication of superhydrophobic surfaces by dislocation-selective chemical etching on aluminum, copper, and zinc substrates. Langmuir 21(20):9007–9009

Bae WG, Song KY, Rahmawan Y, Chu CN, Kim D, Chung do K, Suh KY (2012) One-step process for superhydrophobic metallic surfaces by wire electrical discharge machining. ACS Appl Mater Interfaces 4(7):3685–3691

Balasubramaniam R, Krishnan J, Ramakrishnan N (2002) A study on the shape of the surface generated by abrasive jet machining. J Mater Process Technol 121(1):102–106

Ghobeity A, Getu H, Krajac T, Spelt JK, Papini M (2007) Process repeatability in abrasive jet micro-machining. J Mater Process Technol 190(1–3):51–60

Ephrath LM (1979) Selective etching of silicon dioxide using reactive ion etching with CF4-H2. J Electrochem Soc 126(8):1419–1421

Tachi S, Tsujimoto K, Okudaira S (1988) Low-temperature reactive ion etching and microwave plasma-etching of silicon. Appl Phys Lett 52(8):616–618

Shaw KA, Zhang ZL, Macdonald NC (1994) Scream i: a single mask, single-crystal silicon, reactive ion etching process for microelectromechanical structures. Sensors Actuators A-Phys 40(1):63–70

Lammertink RGH, Hempenius MA, van den Enk JE, Chan VZH, Thomas EL, Vancso GJ (2000) Nanostructured thin films of organic-organometallic block copolymers: one-step lithography with poly(ferrocenylsilanes) by reactive ion etching. Adv Mater 12(2):98–103

Mineta T (2004) Basic characteristics of an electrochemical etching of Ni-Fe containing corrosion resistant alloys. Sensors Actuators A-Phys 114(2–3):536–542

Datta M, Harris D (1997) Electrochemical micromachining: an environmentally friendly, high speed processing technology. Electrochim Acta 42(20–22):3007–3013

Bhattacharyya B, Munda J, Malapati M (2004) Advancement in electrochemical micro-machining. Int J Mach Tools Manuf 44(15):1577–1589

Lee ES, Park JW, Moon YH (2002) A study on electrochemical micromachining for fabrication of microgrooves in an air-lubricated hydrodynamic bearing. Int J Adv Manuf Technol 20(10):720–726

Munda J, Bhattacharyya B (2008) Investigation into electrochemical micromachining (EMM) through response surface methodology based approach. Int J Adv Manuf Technol 35(7–8):821–832

Spieser A, Ivanov A (2013) Recent developments and research challenges in electrochemical micromachining (A mu ECM). Int J Adv Manuf Technol 69(1–4):563–581

Jiang LM, Li W, Attia A, Cheng ZY, Tang J, Tian ZQ, Tian ZW (2008) A potential method for electrochemical micromachining of titanium alloy Ti6Al4V. J Appl Electrochem 38(6):785–791

Tang J, Zhang L, Tian X (2010) Micromachining on copper and nickel by electrochemical wet stamping. J Micromech Microeng 20(11):115030

Kern P, Veh J, Michler J (2007) New developments in through-mask electrochemical micromachining of titanium. J Micromech Microeng 17(6):1168–1177

Dar-Yuan C, Ping-Chen S, Jung-Chou H, Shuo-Jen L, Hai-Ping T (2012) Process simulation-assisted fabricating micro-herringbone grooves for a hydrodynamic bearing in electrochemical micromachining. Mater Manuf Process 26(12):1451–1458

Hong Shik S, Bo Hyun K, Chong Nam C (2008) Analysis of the side gap resulting from micro electrochemical machining with a tungsten wire and ultrashort voltage pulses. J Micromech Microeng 18(7):6, 075009

Lee ES, Baek SY, Cho CR (2007) A study of the characteristics for electrochemical micromachining with ultrashort voltage pulses. Int J Adv Manuf Technol 31(7–8):762–769

Lee ES, Baek SY, Lee JT (2009) Characteristics for electrochemical machining with nanoscale voltage pulses. J Nanosci Nanotechnol 9(6):3424–3432

Maurer JJ, Hudson JL, Fick SE, Moffat TP, Shaw GA (2012) Electrochemical micromachining of NiTi shape memory alloys with ultrashort voltage pulses. Electrochem Solid State Lett 15(2):D8–D10

Gherca A, Fatu A, Hajjam M, Maspeyrot P (2013) Influence of surface geometry on the hydrodynamic performances of parallel bearings in transient flow conditions. Tribol Trans 56(6):953–967

Gherca AR, Gherca AR, Maspeyrot P, Hajjam M, Fatu A (2013) Influence of texture geometry on the hydrodynamic performances of parallel bearings. Tribol Trans 56(3):321–332

Rahmani R, Rahmani R, Mirzaee I, Shirvani A, Shirvani H (2010) An analytical approach for analysis and optimisation of slider bearings with infinite width parallel textures. Tribol Int 43(8):1551–1565

Scaraggi M (2012) Textured surface hydrodynamic lubrication: discussion. Tribol Lett 48(3):375–391

Tauviqirrahman M, Ismail R, Jamari J, Schipper DJ (2013) A study of surface texturing and boundary slip on improving the load support of lubricated parallel sliding contacts. Acta Mech 224(2):365–381

Traore MM, Wang L (2013) Influences of the flow speed and the micro-texture deepness on the hydrodynamic lubrication characteristics. J Comput Theor Nanosci 10(2):419–422

Wahl R, Schneider J, Gumbsch P (2012) Influence of the real geometry of the protrusions in micro textured surfaces on frictional behaviour. Tribol Lett 47(3):447–453

Tang W, Zhou YK, Zhu H, Yang HF (2013) The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl Surf Sci 273:199–204

Rao TVVLN, Rani AMA, Nagarajan T, Hashim FM (2012) Analysis of slider and journal bearing using partially textured slip surface. Tribol Int 56:121–128

Rao TVVLN, Rani AMA, Nagarajan T, Hashim FM (2014) Analysis of couple stress fluid lubricated partially textured slip slider and journal bearing using narrow groove theory. Tribol Int 69:1–9

Sinanoglu C (2009) Investigation of load carriage capacity of journal bearings by surface texturing. Ind Lubr Tribol 61(5):261–270

Sinanoglu C, Nair F, Goeksen E (2008) Effect of micro and macro pits of journal surface on radial pressure distribution of journal bearing. Ind J Eng Mater Sci 15(4):300–310

Hao XQ, Wang L, Wang QD, Guo FL, Tang YP, DingmYC LBH (2011) Surface micro-texturing of metallic cylindrical surface with proximity rolling-exposure lithography and electrochemical micromachining. Appl Surf Sci 257(21):8906–8911

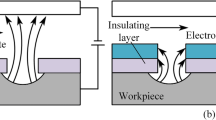

Wang L, Wang QD, Hao XQ, Ding YC, Lu BH (2010) Finite element simulation and experimental study on the through-mask electrochemical micromachining (EMM) process. Int J Adv Manuf Technol 51(1–4):155–162

de Silva AKM, McGeough JA (1998) Process monitoring of electrochemical micromachining. J Mater Process Technol 76(1–3):165–169

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 222 kb)

Rights and permissions

About this article

Cite this article

Hao, X., Pei, S., Wang, L. et al. Microtexture fabrication on cylindrical metallic surfaces and its application to a rotor-bearing system. Int J Adv Manuf Technol 78, 1021–1029 (2015). https://doi.org/10.1007/s00170-014-6648-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6648-z