Abstract

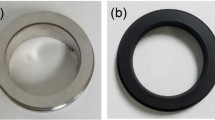

Surface texturing as a means for enhancing tribological properties of mechanical components has been under intensive investigation over the last two decades. Many methods have been proposed to create surface texture of various patterns and geometries. However, among all these methods, deformation-based micro-surface texturing is least studied. It has many advantages over other methods that could lead to immediate industry application, including high productivity, high geometry fidelity and low cost. In the current work, a simple but effective incremental micro embossing system based on a commercially available press has been developed to create micro surface textures of various shapes and depths with accuracy up to 5 μm. The friction coefficients of the textured surfaces have been tested at different loadings and speeds with various lubricants to demonstrate their friction reduction capability. It has been observed that at high speed conditions, the friction reduction is achieved by the hydrodynamic lift. Interestingly, at the low speed conditions, the micro-surface texture is still capable of reducing the friction, thanks to its lubricant retention and debris entrapment capability. A micro surface textured mechanical face seal demonstrator has been built to further evaluate the micro surface texture created by incremental embossing method. A reduction of 20% in torque friction has been consistently achieved, which is on a par with that of the laser surface texturing method.

Similar content being viewed by others

References

Bruzzone, A. A. G., Costa, H. L., Lonardo, P. M., and Lucca, D. A., “Advances in Engineered Surfaces for Functional Performance,” CIRP Annals-Manufacturing Technology, Vol. 57, No. 2, pp. 750–769, 2008.

Hamilton, D. B., Walowit, J. A., and Allen, C. M., “A Theory of Lubrication by Microirregularities,” Journal of Basic Engineering, Vol. 88, No. 1, pp. 177–185, 1966.

Anno, J. N., Walowit, J. A., and Allen, C. M., “Microasperity Lubrication,” Journal of Lubrication Technology, Vol. 90, No. 2, pp. 351–355, 1968.

Anno, J. N., Walowit, J. A., and Allen, C. M., “Load Support and Leakage from Microasperity-Lubricated Face Seals,” Journal of Lubrication Technology, Vol. 91, No. 4, pp. 726–731, 1969.

Tian, H., Saka, N., and Suh, N. P., “Boundary Lubrication Studies on Undulated Titanium Surfaces,” Tribology Transactions, Vol. 32, No. 3, pp. 289–296, 1989.

Tønder, K., “Inlet Roughness Tribodevices: Dynamic Coefficients and Leakage,” Tribology International, Vol. 34, No. 12, pp. 847–852, 2001.

Han, J., Fang, L., Sun, J., and Ge, S., “Hydrodynamic Lubrication of Microdimple Textured Surface using Three-Dimensional CFD,” Tribology Transactions, Vol. 53, No. 6, pp. 860–870, 2010.

Greco, A., Raphaelson, S., Ehmann, K., Wang, Q. J., and Lin, C., “Surface Texturing of Tribological Interfaces using the Vibromechanical Texturing Method,” Journal of Manufacturing Science and Engineering, Vol. 131, No. 6, Paper No. 061005, 2009.

Brinksmeier, E., Riemer, O., and Twardy, S., “Tribological Behavior of Micro Structured Surfaces for Micro Forming Tools,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 4, pp. 425–430, 2010.

Graham, E., Park, C. I., and Park, S. S., “Fabrication of Micro-Dimpled Surfaces through Micro Ball End Milling,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 9, pp. 1637–1646, 2013.

Byun, J. W., Shin, H. S., Kwon, M. H., Kim, B. H., and Chu, C. N., “Surface Texturing by Micro ECM for Friction Reduction,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 5, pp. 747–753, 2010.

Etsion, I., “State of the Art in Laser Surface Texturing,” Journal of Tribology, Vol. 127, No. 1, pp. 248–253, 2005.

Etsion, I. and Burstein, L., “A Model for Mechanical Seals with Regular Microsurface Structure,” Tribology Transactions, Vol. 39, No. 3, pp. 677–683, 1996.

Etsion, I. and Halperin, G., “A Laser Surface Textured Hydrostatic Mechanical Seal,” Tribology Transactions, Vol. 45, No. 3, pp. 430–434, 2002.

Etsion, I., Kligerman, Y., and Halperin, G., “Analytical and Experimental Investigation of Laser-Textured Mechanical Seal Faces,” Tribology Transactions, Vol. 42, No. 3, pp. 511–516, 1999.

Ronen, A., Etsion, I., and Kligerman, Y., “Friction-Reducing Surface-Texturing in Reciprocating Automotive Components,” Tribology Transactions, Vol. 44, No. 3, pp. 359–366, 2001.

Ryk, G., Kligerman, Y., and Etsion, I., “Experimental Investigation of Laser Surface Texturing for Reciprocating Automotive Components,” Tribology Transactions, Vol. 45, No. 4, pp. 444–449, 2002.

Brizmer, V., Kligerman, Y., and Etsion, I., “A Laser Surface Textured Parallel Thrust Bearing,” Tribology Transactions, Vol. 46, No. 3, pp. 397–403, 2003.

Dekkers, H. F. W., Duerinckx, F., Szlufcik, J., and Nijs, J., “Silicon Surface Texturing by Reactive Ion Etching,” Opto-Electronics Review, Vol. 8, No. 4, pp. 311–316, 2000.

Zhou, R., Cao, J., Ehmann, K., and Xu, C., “An Investigation on Deformation-based Surface Texturing,” Journal of Manufacturing Science and Engineering, Vol. 133, No. 6, Paper No. 061017, 2011.

Pettersson, U. and Jacobson, S., “Tribological Texturing of Steel Surfaces with a Novel Diamond Embossing Tool Technique,” Tribology International, Vol. 39, No. 7, pp. 695–700, 2006.

Pettersson, U. and Jacobson, S., “Textured Surfaces for Improved Lubrication at High Pressure and Low Sliding Speed of Roller/ Piston in Hydraulic Motors,” Tribology International, Vol. 40, No. 2, pp. 355–359, 2007.

Ma, C. and Zhu, H., “An Optimum Design Model for Textured Surface with Elliptical-Shape Dimples under Hydrodynamic Lubrication,” Tribology International, Vol. 44, No. 9, pp. 987–995, 2011.

Qiu, M., Minson, B. R., and Raeymaekers, B., “The Effect of Texture Shape on the Friction Coefficient and Stiffness of Gas-Lubricated Parallel Slider Bearings,” Tribology International, Vol. 67, pp. 278–288, 2013.

Etsion, I., “Improving Tribological Performance of Mechanical Components by Laser Surface Texturing,” Tribology Letters, Vol. 17, No. 4, pp. 733–737, 2004.

Yu, X., He, S., and Cai, R., “Frictional Characteristics of Mechanical Seals with a Laser-Textured Seal Face,” Journal of Materials Processing Technology, Vol. 129, No. 1, pp. 463–466, 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, S., An, S.O.J., Atsushi, D. et al. Development of low-cost deformation-based micro surface texturing system for friction reduction. Int. J. Precis. Eng. Manuf. 17, 1059–1065 (2016). https://doi.org/10.1007/s12541-016-0128-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0128-3