Abstract

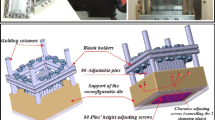

As a flexible forming method for sheet metal part, multi-point forming (MPF) technology is discussed in the paper. It employs two reconfigurable element groups to approximate the continuous upper and lower solid dies. With the technique, rapid fabrication of 3D sheet metal part is realized. The principles of multi-point die forming (MPDF) and multi-point press forming (MPPF) are described and then the rules to determine the size of the element are given. For any spatial shape surface to be formed, all elements’ height can be calculated through the contacting point calculation equation. On the computer control, the shape of the two element groups can be adjusted by serial adjusting mode or parallel adjusting mode. MPDF apparatus that includes CAD software, computer control system, two element groups, hydraulic press and laser CMM is developed. Following the given MPF procedure, 3D sheet metal part was formed without failure. Due to the rapid change characteristics of the two element groups, several special MPF forming techniques that are impossible in conventional sheet forming have been investigated in detail. By flexible blank holder technique, thin sheet MPDF is realized. With sectional MPF, large size sheet would be formed on small scale MPF apparatus. Through closed loop MPF, spring-back would be compensated cycle by cycle, and large deformation part is obtained with incremental MPDF successfully.

Similar content being viewed by others

References

Nakajima N (1969) A newly developed technique to fabricate complicated dies and electrodes with wires. J Japan Soc Mech Eng 72(603):498–506

Hardt DE, Gossard DC (1980) A variable geometry die for sheet metal forming: machine design and control. Proc Jt Autom Control Conf., USA No.2, FP7–C:1–5

Webb RD, Hardt DE (1991) A Transfer Function Description of Sheet Metal Forming for Process Control. Trans ASME, J Eng Ind 113:44–52

Valjavec M, Hardt DE (1999) Closed-loop shape control of the stretch forming process over a reconfigurable tool: precision airframe skin fabrication. Proc ASME, Manuf Eng Division 10:909–919

Finckenstein EV, Kleiner M (1991) Flexible numerically controlled tool system for hydro-mechanical deep drawing. Ann CIRP 40:311–314

Li M, Nakamura H, Watanabe S (1992) Study of the basic forming principles (1st Report: Research on multi-point forming for sheet metal). Proc Japanese Spring Conference for Technology of Plasticity, pp 519–522

Li M, Nakamura H, Shima A (1992) Occurring and controlling of defects in multi-point forming (3rd Report: Research on multi-point forming for sheet metal). Proc Japanese No.43 Conference for Technology of Plasticity, pp 425–428

Li M, Liu Y (1999) Multi-point forming: a flexible manufacturing method for a 3-d surface sheet. J Mater Process Technol 87:277–280

Cai Z, Li M (2001) Optimum path forming technique for sheet metal and its realization in Multi-point forming. J Mater Process Technol 110(2):136–141

Li MZ, Cai ZY, Sui Z, Yan QG (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129(1–3):333–338

Cai ZY, Li MZ (2005) Finite element simulation of multi-point sheet forming process based on implicit scheme. J Mater Process Technol 161(3):449–455

Sui Z, Liu C, Li M, Cui X (2005) Working surface design and control in multi-point forming of sheet metal. Proc 8th International Conference on Technology of Plasticity, Verona, Italy, October 2005, pp 581–582

Liu C, Li M, Cai Z (2004) Rapid manufacturing system for sheet metal parts and its application. Proc 6th International Conference on Frontiers of Design and Manufacturing, Science Press & Science Press USA, June 2004, pp 708–709

Liu CG, Li MZ, Cui XJ (2004) Spring-back self adaptive control in multi-point forming of sheet metal. Proc 1st International Conference on New Forming Technology, Sept 2004, Harbin, pp 303–308

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., Li, M. & Fu, W. Principles and apparatus of multi-point forming for sheet metal. Int J Adv Manuf Technol 35, 1227–1233 (2008). https://doi.org/10.1007/s00170-006-0802-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0802-1