Abstract

Industry 4.0 (i4.0) is central to advanced manufacturing. Building on novel digital technologies, it enables smart and flexible manufacturing with systems connected across company boundaries and product lifecycle phases. Despite its benefits, the adoption of i4.0 has been limited, especially in small and medium-sized enterprises. A key challenge is the technological complexity of i4.0. While advanced functionality requires technological complexity, it complicates an understanding of which enabling technologies are particularly useful and required. This article presents a framework to support successful i4.0 adoption across the entire product generation process through a systematic matrix-based dependency analysis of i4.0 solutions and underlying i4.0 technologies. Through increasing transparency around technological complexity of i4.0 solutions, this research contributes to a better understanding of which technologies are required for specific i4.0 solutions and which technologies could be strategic enablers for a broad variety of i4.0 applications. Knowing these technological dependencies supports both, the systematic adoption of existing i4.0 solutions and the development of new i4.0 solutions. This also sets the basis for a future socio-technical investigation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

This article develops a framework to structure the complex dependencies between Industry 4.0 (i4.0) applications, so-called technology solutions (tech-solution), and enabling technologies. This framework supports technology and production mangers to better understand what technologies they need for a successful i4.0 adoption across the product generation process as well as to design future i4.0 solutions.

Industry 4.0 (i4.0) has become a central concept for contemporary and advanced manufacturing (Frank et al. 2019). i4.0 represents a collection of technologies rather than a single technology (Xu et al. 2018). A key feature is the integration and networking of manufacturing processes within organizations as well as along supply chains, enabled through advancements in information and communication technologies (ICT) and competences. It allows a holistic collaboration between machines, resources and humans, along with a paradigm shift from a centralised to a more decentralised way of control (Kagermann 2015). This supports companies in shortening product development times, providing increasingly customised products, realizing higher flexibility in product development and manufacturing, as well as increasing resource efficiency and sustainability (Lasi et al. 2014). While the adoption of i4.0 is based on the implementation of i4.0 technologies, these are normally not acquired individually but as part of a purpose-oriented tech-solution: for instance, an additive manufacturing machine alone does not provide much value in isolation but requires enabling technologies like CAD software and computers, and post-processing along with a use or business case to form an additive manufacturing solution. This also highlights that i4.0 can create the highest value if adopted along the entire product generation process from product planning to manufacturing.

Despite these benefits, the adoption of i4.0 in companies is challenging (Pedota et al. 2023) and adoption rates lower than expected (Bajic et al. 2021). Initial studies indicate that central adoption challenges range from a limited understanding of i4.0, via gaps in capabilities and system integration, to high investment costs. They cause a high risk of adopting i4.0 technologies that cannot be used to their full extent or that do not add value to the company (Bag and Pretorius 2022; Orzes et al. 2020; Wichmann et al. 2019; Yu and Schweisfurth 2020; Zhou and Le Cardinal 2019). Especially small and medium-sized enterprises (SMEs) tend to be generally cautious or even reluctant to invest in new technologies as their economic benefit and risk are not sufficiently assessable (Bajic et al. 2021; Erol et al. 2016; Orzes et al. 2020; Raj et al. 2020). Along with often limited resources that hinder from closely following the latest evolutions of i4.0 technologies and i4.0 applications, competence and cultural challenges contribute to i4.0 adoption reluctance (Bajic et al. 2021; Cotrino et al. 2020; Faller and Feldmüller 2015; Orzes et al. 2020). This is further complicated by a lack of a methodological approach and support around the adoption of i4.0 (Orzes et al. 2020; Raj et al. 2020; Yu and Schweisfurth 2020). In addition, technical issues such as lacking compatibility (Ghobakhloo et al. 2022) can cause various technical implementation challenges (Bajic et al. 2021; Khaitan and McCalley 2015; Raj et al. 2020; Zhou and Le Cardinal 2019).

The majority of these adoption challenges is directly or indirectly linked to complex technological interdependencies of i4.0. Pedota et al. (2023) stress that technologies form complex systems comprising complementary and interdependent single technologies (Ghobakhloo et al. 2022; Pedota et al. 2023). While the adoption of i4.0 requires the implementation of digital technologies (Frank et al. 2019), the underlying technological change in itself is neither simple nor self-sufficient, and especially the mere adoption of technologies is not sufficient for a company to create competitive advantages (Pedota et al. 2023). Often, the limited focus on specific technologies leaves the full potential of i4.0 benefits underutilised (Bittighofer et al. 2018; Schneider et al. 2021). However, the resulting technological complexity is a double-sided sword.

On one hand, advanced i4.0 functionality and performance require technological complexity. Only the purposeful and consistent combination of complementary technologies as part of an overarching architecture enables novel system properties and applications or tech-solutions (Pedota et al. 2023). This aligns with the wish of companies to only invest into socio-technical capabilities they need. This means they want technologies to achieve a specific purpose. They are not so much interested in single i4.0 technologies but rather consistent combination of technologies, i.e. i4.0 tech-solutions for specific use cases (Pedota et al. 2023). For instance, while additive manufacturing would be a technology, its combination with artificial intelligence and cloud computing could allow for an i4.0 tech-solution around rapid product development including optimised material selection (Pedota et al. 2023). The example also highlights the wish of SMEs as well as the general relevance of considering not only the manufacturing phase but the entire product generation process to utilise the full potential of i4.0 and underlying investments.

On the other hand, the high i4.0 technological complexity is a major challenge (Frank et al. 2019; Ghobakhloo et al. 2022; Kumar et al. 2020; Schott et al. 2020; Volkwein et al. 2022). Along with the variety and novelty of i4.0 technologies (Müller et al. 2018), it complicates an understanding of what technologies are required for a specific i4.0 tech-solution, and whether or how new technologies are compatible with other new or existing technologies (Ghobakhloo et al. 2022) as well as staff competences, processes, organizational change, and even the overarching company strategy (Agostini and Nosella 2020; Calabrese et al. 2020). This aligns with other studies that link complexity to an uncertainty and limited common understanding of which and how to use new technologies and their combinations (Marri et al. 1998; Morales et al. 2023). Compared to Industry 3.0 with elements such as Computer Integrated Manufacturing (CIM), i4.0 integrates the physical and virtual domain and connects vast networks of artificial intelligence-enabled decentralised systems (Ahuett-Garza and Kurfess 2018; Xu et al. 2018), which drastically increases the resulting complexity. Especially for SMEs, i4.0 is an “intimidating concept” (Ramírez-Durán et al. 2021). Their resource constraints (Ghobakhloo et al. 2022; Yu and Schweisfurth 2020) can limit their ability to follow the latest technological trends as well as increase the risk when buying unsuitable or incompatible technologies. In addition, there is an economic incentive to select technologies that can be used not only for a single tech-solution but for several different i4.0 tech-solutions. This spans across the product generation process, such as using virtual reality to visualise a new product prototype as well as how specific manufacturing tasks could be conducted. Most of these challenges had already been reported for i3.0 and CIM with their internal focus and rigid system architecture tailored towards process efficiency (Marri et al. 1998) and still caused issues when i4.0 started to rise (İç, 2012). However, the open, externally oriented system architecture of i4.0 including artificial intelligence, increased amounts and importance of data, and integrated cyber-physical domains allow not only for process efficiency but also situational flexibility (Marri et al. 1998; Yu et al. 2015), which amplifies these challenges and requires new methodical support.

This means understanding and managing complex interdependencies between i4.0 technologies and i4.0 tech-solutions is critical for the successful adoption of i4.0, but has only received limited attention to date. Representing a first step on a longer research journey towards the successful adoption of i4.0 including socio-technical and economic considerations, this leads to the following research question: How can dependencies between i4.0 tech-solutions in the product generation process and underlying enabling technologies be analysed and mapped? This includes the question: How can i4.0 technologies and solutions be systematically structured?

To answer these questions, we take a holistic focus on the product generation process: ranging from product planning, via product development and production planning, to production (Naefe and Luderich 2016; Schneider et al. 2021). First, we analyse literature on i4.0 technologies and tech-solutions to develop a consistent taxonomy of i4.0 technologies and a structured overview of i4.0 tech-solutions. This is critical to address the varying levels of abstraction and resulting understanding of i4.0 technologies, for instance, ranging from abstract additive manufacturing down to specific wire arc additive manufacturing. These structures serve as basis for a systematic analysis of solution-technology dependencies, leading to an i4.0 solution-technology framework to support successful i4.0 adoption. Applying the framework to an existing cyber-physical brewery evaluates and showcases the framework applicability.

Thus, this research contributes to i4.0 adoption through a more systemic perspective, broadening the scope from single technologies (Bajic et al. 2021) to purposeful technology combinations, so-called tech-solutions, for specific applications. Our research helps to increase transparency around technological complexity of these i4.0 tech-solutions. It adds to an improved understanding of requirements and prerequisites for implementing specific i4.0 tech-solutions and will help academics and practitioners investigating occurring adoption issues from a technological dependency perspective. While this contributes to adopting i4.0 tech-solutions that support product development and manufacturing, it helps practitioners like manufacturing managers or integrators via guiding the design and development of new i4.0 tech-solutions in the medium-term future. This also sets a basis for future research also considering non-technical adoption aspects as part of a socio-technical research perspective (Polojärvi et al. 2023), which can form the basis to develop methodical support for the planning and management of i4.0 adoption (Orzes et al. 2020; Yu and Schweisfurth 2020).

The remainder of this paper is structured as follows: Sect. 2 provides an overview of the key concepts of i4.0, the difference between technologies and tech-solutions. Section 3 describes the process of our literature analysis, technology and tech-solution mapping and resulting framework development. The outcomes are presented in Sect. 4. Section 5 discusses the implications on i4.0 adoption, including a pre-evaluation of the framework with a cyber-physical brewery. Section 6 concludes the paper and details the respective contributions and limitations.

2 Conceptualising Industry 4.0 technologies and tech-solutions

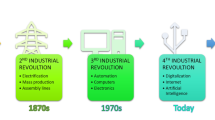

The term Industry 4.0 (i4.0) or 4th Industrial Revolution was introduced at the Hannover Fair 2011 to describe a radical shift in manufacturing: while Industry 1.0 was characterised by steam-powered machines in the eighteenth century, Industry 2.0 by conveyer belts, electrical energy, and mass production in the nineteenth and twentieth century, Industry 3.0 by automated manufacturing using programmable logic controllers, Industry 4.0 is characterised by smart autonomous decentralised but highly interconnected cyber-physical systems that integrate virtual and physical domains (Ahuett-Garza and Kurfess 2018; Xu et al. 2018). A key element of i3.0 is Computer Integrated Manufacturing (CIM), which has been closely linked to the rise of digital manufacturing in the 1980s (Yu et al. 2015). CIM is a generic term of a group of technologies, including manufacturing machines, IT and software, to produce products more efficiently through an automated process from order reception, CAD design, production to shipping of a product (Marri et al. 1998). This automatization is achieved through the vertical integration of computers and manufacturing systems as part of localised networks of embedded systems within a single factory using a closed, hierarchical and rigid architecture (Yu et al. 2015). This limits the ability to deal with external changes (Yu et al. 2015). Thus, the key focus of CIM is on increasing process efficiency and quality, and reducing costs and production times (Marri et al. 1998). In contrast, the driving aspects of i4.0 are Cyber-Physical Systems (CPS) and Cloud Computing (CP) (Yu et al. 2015). They enable a vertical and horizontal integration and connection amongst machines, between machines and humans, and along the value-chain, which builds global networks of embedded systems and ultimately factories and companies. Along with increased process efficiency, this also fosters a high degree of flexibility and adaptability (Yu et al. 2015). Hence, following the statement of İç (2012, p. 245) that “CIM refers to any computer-oriented technologies used in design, manufacturing and logistics operations”, i4.0 including CPS and CS undeniably build upon CIM but enhance it by new technologies and features. Especially the use of cloud services, internet of things, and artificial intelligence along with a shift from mass manufacturing to flexible customised manufacturing differentiate i4.0 from i3.0 (Jiang et al. 2022; Yin et al. 2018).

The term i4.0 has been used extensively since its introduction, leading to slightly varying definitions and understandings of i4.0 (Klingenberg et al. 2021). Analysing different i4.0 definitions reveals variations that are rooted in different overarching perspectives onto i4.0. These can be grouped into three main views: (1) Technology-centric view, focussing on underlying technologies, i.e. i4.0 as a collective term of using different i4.0 technologies (e.g. Hermann et al. 2016; Lopez-Gomez et al. 2017); (2) Concept-centric view, focussing on organisational and manufacturing philosophical aspects, i.e. organizational and technological change following an automation philosophy (Nosalska et al. 2020; Oztemel and Gursev 2020); and (3) Networking-centric view, focussing on system interconnections, i.e. networking of machines, humans and organizations in real time (Bauer et al. 2014; Bauernhansl et al. 2014).

Nevertheless, all views share common characteristics, such as an overarching connectivity between suppliers and customers, digitalization and smart manufacturing, based on the extensive use of cyber-physical systems (Müller et al. 2018). Hermann et al. (2016) state interconnection, information transparency, decentralised decision and technical assistance as key characteristics of i4.0. This means, i4.0 is characterised by the use of novel technologies, which allow for high-level of connectedness of socio-technical systems, but also require substantial changes of machines, humans, organizations and industries. These aspects are summarised in the i4.0 definition of Nosalska et al. (2020): “Industry 4.0 is a concept of organizational and technological changes along with value chains integration and new business models development that are driven by customer needs and mass customization requirements and enabled by innovative technologies, connectivity and IT integration.”.

2.1 A taxonomy of industry 4.0 technologies

Technologies generally represent “a system of knowledge about how to manipulate nature in a logical scheme to achieve a functional transformation” (Betz 2011). Although the term technology thus describes broadly the ability and knowledge to achieve such a transformation (Gochermann 2022), often based on scientific insights, it is usually associated with hardware and software, such as additive manufacturing and big data (Nosalska et al. 2020). Purposefully combined, compatible technologies provide new functions and enable the adoption of i4.0 in terms of i4.0 tech-solutions (Kang et al. 2016).

In addition to the continuously growing variety of technologies, a key challenge of systematically managing technologies is a varying degree of abstraction in literature, e.g. ranging from specific, such as deep learning, to abstract, such as general artificial intelligence. A clear taxonomy is key to ensure a unified understanding of what is actually described, managed or applied. To manage this complexity, such a taxonomy needs to be able to incorporate and clearly structure technologies on different levels of abstraction to differentiate between single technologies and groups of technologies. Due to the fast-paced technological development, another requirement is to allow for future updates, i.e. adding, deleting, and modifying technologies and groups. This includes a robust mapping with i4.0 solutions to allow for adding, deleting, and modifying technologies, groups, and tech-solutions without affecting the rest of the mapping framework. A range of existing studies have categorised i4.0 technologies in different ways and with different foci. This paper builds on this wealth of prior knowledge and combines these insights in a taxonomy that fulfils the requirements of allowing varying levels of abstraction, future updates, and a robust mapping of i4.0 technologies with i4.0 solutions.

Bueno et al. (2020) use a rough five-item technology categorisation of internet of things (IoT), cyber-physical systems (CPS), additive manufacturing (AM), cloud manufacturing, and big data and analytics/AI, and map these onto different capabilities and applications for production scheduling and control. This provides a systematic overview of technology potentials but lacks a detailed technology categorisation and consideration of other product generation phases. Zheng et al. (2021) provide a broader view, both in terms of considering different product lifecycle phases and presenting a more detailed analysis of 10 technology types, which adds to the five categories of Bueno et al. (2020): IoT, CPS, AM, cloud technologies, big data and analytics, AI, blockchain, simulation and modelling, visualisation technologies, and automation and industrial robots. Dalmarco et al. (2019) describe nine technology groups: simulation, big data and analytics, cloud computing, cyber-physical systems, cybersecurity, collaborative robotics, augmented reality, additive manufacturing, and systems integration. Although they explain that these technologies are linked to developing, manufacturing, operating and servicing activities, the specific links to the activities and to each other are not clear. In this respect, the framework of Lopez-Gomez et al. (2017) analyses interdependencies of technologies. It uses a data perspective to structure i4.0 technologies into four groups including subgroups: data generation and capture (incl. CPS), data transmission (incl. network infrastructure), data conditioning, storage and processing (incl. big data and cloud computing), and data application (incl. advanced manufacturing capabilities). However, the framework does only mention a limited number of technologies for each group. Lee et al. (2015) also use a data perspective to build their hierarchical 5C CPS architecture: smart connection level (e.g. sensors), data-to-information conversation level (e.g. smart machine components), cyber level (e.g. digital twins), cognition level (e.g. collaborative diagnostics and decision making), and configuration level (e.g. self-optimising systems). Although the hierarchical levels building on each other are a powerful concept, they focus on a production system as ultimate goal and put less focus on smart individual machines or product development phases. Calabrese et al. (2020) analyse the relationship between i4.0 goals, technologies, and barriers, based on a structure of nine technology classes reflecting different i4.0 use case areas: production line, smart worker, smart equipment, computing, sharing, smart product, data analytics, network, and cyber-security technologies.

The comparison of these framework shows distinctive similarities, where Bueno et al. (2020) can be seen as a subset of Zheng et al. (2021). In respect of a consolidated i4.0 technology taxonomy, a central category are manufacturing technologies, which enhance manufacturing capabilities and their level of automation and autonomy, and can be more generally addressed as production line (Calabrese et al. 2020), abstractly as data application (Lopez-Gomez et al. 2017), or more specifically as AM or robots (Dalmarco et al. 2019; Zheng et al. 2021). Computing technologies (Calabrese et al. 2020) correspond with data conditioning, storage and processing (Lopez-Gomez et al. 2017) and include cloud technologies (Dalmarco et al. 2019; Zheng et al. 2021). They enable the sharing and provision of computing power and resources across business processes. They also improve the exchange and processing of data across company boundaries. While data technologies also overlap with data conditioning, storage and processing, their focus is more on data analytics (Calabrese et al. 2020; Dalmarco et al. 2019), including big data, AI and blockchain (Zheng et al. 2021). They enable advanced analysis, management and secure storage of data that forms the heart of i4.0 (Inkermann et al. 2019). Closely linked are simulation technologies (Dalmarco et al. 2019), which also include modelling (Zheng et al. 2021) and computing, and represent a form of data application (Lopez-Gomez et al. 2017). They combine technologies for the simulation and the optimization of business activities, ranging from technologies like ERP, MES and CIM/CAx novel technologies like advanced simulation for predictive control and problem solving (Modrák and Mandul’ák 2009). While human interface technologies are not explicitly addressed, they correlate with smart worker, smart product and smart equipment (Calabrese et al. 2020) in respect to data generation and capture and data application (Lopez-Gomez et al. 2017), including visualisation (Zheng et al. 2021). They can range from partially immersive augmented, where real-world elements are combined with the virtual reality, to fully immersive ways to visualise data and images. Network technologies combine sharing and network (Calabrese et al. 2020) and IoT (Zheng et al. 2021) in the sense of data transmission (Lopez-Gomez et al. 2017) as well as integration (Dalmarco et al. 2019). They enable the i4.0-inbuilt networking of machines and humans in real time (Bauernhansl et al. 2014; Lee et al. 2015) and show strong links to cloud-based computing technologies. Sensor technologies are not explicitly mentioned but are critical is respect to data generation and capture (Lopez-Gomez et al. 2017) as they connect the physical and digital side of i4.0 through capturing real-world data (Szász et al. 2021). While this enables smart i4.0 systems, these novel sensors are smart themselves as they are autonomous interconnected systems. An increasingly crucial category but only mentioned by Calabrese et al. (2020) and Dalmarco et al. (2019) are cyber security technologies. They protect hardware and software i4.0 infrastructure from unauthorised access, tempering or attacks (Bajic et al. 2021). Despite their relevance, the analysed literature surprisingly did not state specific technologies. Figure 1 provides an overview of the consolidated i4.0 technology taxonomy (with more details in Appendices 1 and 2). Its three-level structure allows to allocate technologies on different levels of abstraction and differentiate specific technologies from technology groups. It also supports its time-robustness as new technologies can be added to existing sub-categories. As cyber-physical systems (CPS) combine several technology categories, they cannot be mapped to a single category and are, therefore, not mentioned in the taxonomy.

2.2 Industry 4.0 technology-solutions

Technology-solutions (tech-solutions) are “an implementation of people, processes, information and technologies in a distinct system to support a set of business or technical capabilities that solve one or more business problems” (Gartner 2022). I4.0 tech-solutions are the combination and realization of different technologies within a concrete i4.0 adoption scenario, i.e. a specific application and purpose, such as combining additive manufacturing with artificial intelligence to enable optimised material selection for 3D printing (Pedota et al. 2023). A set of technologies can be combined to various tech-solutions based on different adoption purposes and strategies. The use of i4.0 tech-solutions represents the adoption of i4.0.

Following the idea of i3.0/CIM from CAD design to produced product (Marri et al. 1998), this research uses a holistic lifecycle phase-spanning view on i4.0 tech-solutions across the product generation process, which can be structured into four phases (Fig. 2, and Table 2) or groups based on Naefe and Luderich (2016) and Schneider et al. (2020).

-

1.

Product planning tech-solutions This phase centres around the strategic question of which products should be developed and why. Product planning tech-solutions are at the start of the product development process and help identifying product needs and requirements—originating from both, internal and external sources (Feldman and Page 1984). With respect to i4.0, external sources like customer involvement become more relevant (Wijewardhana et al. 2021). Along with traditional passive involvement types like an analysis of e-commerce platform transaction data (Li et al. 2018), active customer involvement through social networks for open innovation are of increasing interest (Kamble et al. 2018).

-

2.

Product development tech-solutions Based on the preceding planning phase, this phase focusses on developing and designing a product (Wijewardhana et al. 2021). I4.0 tech-solutions can help reduce development times and costs, and improve quality (Wijewardhana et al. 2021). Tech-solutions range from AI-supported colour matching (Wijewardhana et al. 2021) and design support (Frank et al. 2019), via rapid prototyping (Yang et al. 2017; Zawadzki and Żywicki 2016) to virtual (Nosalska et al. 2020) and hybrid prototyping (Kamble et al. 2018).

-

3.

Production planning and control tech-solutions This phase designs the production systems and processes to manufacture a developed product (Vielhaber and Stoffels 2014). This includes factory layout aspects, such as data-driven plant design (Bueno et al. 2020) and digital twin factory floor map planning (Chen 2017), process and workflow aspects, such as AI process optimization (Ramirez-Peña et al. 2020) and e-Kanban systems (Bueno et al. 2020), and control aspects, such as distributed manufacturing control (Bueno et al. 2020) and local real-time process coordination (Fernandez-Carames and Fraga-Lamas 2019). Due to production control focusing on scheduling and monitoring production activities, it overlaps with the subsequent production process (Vielhaber and Stoffels 2014).

-

4.

Production tech-solutions Based on production planning, this phase focuses on the actual manufacturing of a product. These tech-solutions can support in increasing manufacturing capabilities and meet the need for a flexible production system and process as a basis of a “smart factory”. Tech-solutions range from locating parts (Bongomin et al. 2020; Fatorachian and Kazemi 2021; Munsamy et al. 2020; Oztemel and Gursev 2020; Pacchini et al. 2019) to smart machining implementations that allowing for the autonomous planning and execution of tasks based on design data (Xu 2017; Yang et al. 2018). Human robot-collaboration can complement unique human capabilities with machine power and accuracy in manufacturing environments (Cherubini et al. 2016; Gualtieri et al. 2021).

3 Research design and methods

This research follows the structure of the Design Research Methodology (DRM) and covers its first three phases (Blessing and Chakrabarti 2009). The Research Clarification phase, addressed in Sect. 1, clarifies the need for, motivation and background of this research. The Descriptive Study 1, addressed in Sect. 2, uses a systematic literature review to build a deeper understanding of the current situation of i4.0 technologies and tech-solutions. This builds the basis for the Prescriptive Study, addressed in Sect. 4, that develops the tech-solution-technology mapping framework. Following Blessing and Chakrabarti (2009), this also includes a first conceptual evaluation of the framework.

A key element of this research is a literature analysis based on the “Preferred Reporting Items for Systematic Reviews and Meta-Analyses” (PRISMA) (Moher et al. 2009), based on the guidelines of Levy and Ellis (2006). Academic literature is extracted from Elsevier’s Scopus, a leading database with a broad coverage of scholarly literature (Martín-Martín et al. 2018), which includes Scopus-listed databases like IEEE Explore. The search focusses on peer-reviewed journal articles to ensure research quality as well as review articles to get a consolidated overview of i4.0 tech-solutions and technologies, including technological links. This also allows for capturing existing i4.0 taxonomies. The search string in title–abstract–keywords combines “Industry 4.0” with “technology” and “solution” (see Table 1). The search is limited to papers published after 2011 (i.e. “> 2010”) as i4.0 was not officially used before the Hannover Fair 2011 (Wichmann et al. 2019). Following Wohlin (2014), a snowballing approach based on the reference lists of identified papers adds further literature using relatedness to the original search terms as inclusion criteria with a focus on review articles (Liao et al. 2017).

In a next step, the resulting 141 publications are screened based on two exclusion criteria: articles only generally mentioning i4.0, technologies and tech-solutions are excluded as they do not provide relevant descriptions on technology or tech-solution characteristics or their interdependencies, along with articles with no available full-text version.

To set the foundation for the dependency analysis of i4.0 technologies and tech-solutions, the resulting 83 publications were analysed concerning i4.0 tech-solutions and technologies. This led to 63 technologies and 62 tech-solutions. The identified 63 technologies show an irregular distribution along with a highly varying level of abstraction (see Appendix 1, Fig. 4). While the 11 most frequently mentioned technologies account for 70% of all mentions, many technologies were mentioned only once. The latter might be due to a relative novelty (e.g. biosensors and quantum computing) or a merely loose link to i4.0 (e.g. system dynamics and functional magnetic resonance imaging). For most technologies, however, it can be attributed to a strongly varying degree of abstraction, such as deep learning versus general artificial intelligence. To ensure a consistent level of abstraction, the identified technologies were categorised based on the taxonomy in Fig. 1. The identified 62 i4.0 tech-solutions were categorised in respect to the four phases of the product generation process: product planning, product development, production scheduling, and production (Naefe and Luderich 2016; Schneider et al. 2020) (Fig. 2, and Table 2). This was based on the analysis of the description of each tech-solution and its application context.

The dependency analysis and subsequent synthesis used a Domain Mapping Matrix (DMM) (Browning 2016; Danilovic and Browning 2007) to investigate the dependencies between i4.0 tech-solutions and enabling technologies. DMM is a well-established tool in systems engineering and complexity management to model and analyse complex, often socio-technical dependencies between elements of different domains (Danilovic and Sandkull 2005). Due to its matrix nature, it also allows for calculating metrics like row and column sums, or matrix calculations to identify e.g. indirect links. In this case, the DMM supports the analysis of which technologies are required for a specific tech-solution, with technologies building the columns of the DMM and tech-solutions the rows.

In a step-wise process, each DMM cell was analysed for a potential dependency between the associated technology and tech-solution, centred around the guiding question if a technology is required for a specific tech-solution. This was based on explicitly stated dependencies in literature as well as the assessment of three researchers with experience in engineering design and i4.0. Building on the identified dependencies from literature, the researcher assessment was conducted individually first. Subsequently, the individual assessments were compared: aligning links were directly accepted while differing link assessments were discussed to understand the underlying reasons and to agree on a unified assessment. For instance, this led to the deletion of the link between (S1.1) Customer demand analysis and (T6.2) Advanced sensors as re-checking the associated literature implied a more data analysis-oriented angle. Subsequently, column and row sums were calculated to derive indicators for the frequency of technology use and indicators for the complexity of tech-solutions, respectively.

4 Mapping Industry 4.0 technologies and tech-solutions

The individual analyses of i4.0 technologies and tech-solutions already indicated that some tech-solutions use similar combinations of technologies, which, however, can be implemented in different ways. To understand these tech-solution-technology relationships in detail, especially in respect to necessary technological preconditions, a systematic dependency analysis was conducted using a Domain Mapping Matrix (DMM) (Danilovic and Browning 2007).

Table 2 shows the DMM and the resulting i4.0 tech-solution-technology framework. Tech-solutions are modelled as rows and structured according to the four focal product generation process phases. Technologies are depicted as columns and clustered into the identified seven technology groups with a focus on the 26 technology clusters to ensure a homogenous level of detail. Links between tech-solutions and technologies are indicated by an “X” and can be read as “requires”. They are based on information derived from literature and were critically discussed and enhanced. For example, the implementation of hybrid prototyping (i.e. integrated virtual and physical prototyping) for product development requires AR/VR along with advanced sensors, simulations and CAD data as well as additive manufacturing (Kamble et al. 2018). The analysis focused on minimal required technologies, ignoring potential variants, such as “Social Networks for Open Innovation” potentially using special CAD toolkits as well in some cases.

The DMM analysis reveals specific patterns. In general, row sums indicate the number of required technologies for each tech-solution, while column sums indicate how frequently a technology is used across different tech-solutions. The five analysed product planning tech-solutions show a focus on Network, Data (analytics) and Computing technologies. This might align with the fuzzy front-end character of this early phase, which aims at identifying customer needs and innovation opportunities. In comparison, the more tangible character of the subsequent phase is reflected in the 12 product development tech-solutions having strong links to Simulation along with Human interface and Computing technologies. Similarly, the 21 production planning and control tech-solutions also show a focus on Simulation technologies but combined with Sensors and Data technologies. This aligns with a shift of the object of observation during the product generation process, from planning and simulating the product to its manufacturing process. The 24 production process tech-solutions have the highest density of technological links, covering almost all technology groups evenly. This high density along with the relatively high number of manufacturing-related tech-solutions reflects the origin of i4.0 as a manufacturing concept. However, the DMM also indicates an increased use of these technologies for tech-solutions in other product creation and life-cycle phases, aligning with literature (Arromba et al. 2021).

5 Discussion

The DMM analysis reveals specific patterns around general technology use and frequency of technology use as well as complexity of i4.0 tech-solutions and dependencies between technologies. In this respect, the consolidated i4.0 technology taxonomy proved to be useful as it enhanced existing two-level taxonomies and frameworks like Calabrese et al. (2020) and Lee et al. (2015) to a three-level taxonomy. While the top-level categories are usually too abstract and broad for a meaningful mapping, the single technologies at the bottom-level are too detailed for mappings and also face the issue of being outdated quickly due to the dynamic evolution of technologies. Hence, the additional middle-level allows for sufficient detail but is still generic enough to allow for incorporating new technologies in the future. In addition, it also able to deal with and systematise technology descriptions with varying levels of details, such as general additive manufacturing versus specific wire arc additive manufacturing, which would otherwise complicate an understanding of what is required for the successful adoption of an i4.0 tech-solution.

5.1 General technology use

The DMM uncovers a varying use of technologies across the product generation process. While production process tech-solutions show a broad use of technologies, production planning and product development focus on Data and Simulation. The focus of product planning lies on Data and Network technologies. This reflects the characteristics of each phase along with the level of concretisation and maturity of the associated product.

It also reflects the origin of i4.0 as a manufacturing concept and key R&D area. Although a holistic life-cycle-spanning consideration of i4.0 would be important and initial scientific signs in this direction can be observed (e.g. Arromba et al. 2021; Ramírez-Durán et al. 2021), a broad tech-solution of i4.0 beyond manufacturing has been limited to date. This is also evident in our DMM analysis although it has to be treated with care as we only analysed review articles. Due to the retrospective character of reviews, this might cause a time delay of reported i4.0 tech-solutions. Still, this does not affect the general pattern of i4.0 technologies being under-utilised in non-manufacturing related product generation process phases. This represents a major gap as opportunities and synergies to other technology-and-innovation-management approaches are not exploited. For example, i4.0 and open innovation show strong similarities in respect to underlying IT technologies, networked features and organisational openness, which would be beneficial to build integrated industry ecosystems if combined.

5.2 Most frequently used technologies

The sum of links of each DMM column indicates how frequently specific i4.0 technologies are used in i4.0 tech-solutions. Three groups—low, medium and high frequency of use—can be differentiated, using the maximum value of 39 to derive three evenly spaced groups. Knowing the groups can support companies in their investment decisions: high frequency can indicate mature technologies with limited adoption risks (cf. Núñez-Merino et al. 2020), which might also be central enabling technologies (cf. Pedota et al. 2023), i.e. representing future-proof investments that are applicable for a large variety of tech-solutions.

Low frequency of use (0–13 links) these represent technologies from current niche applications as well as low level of maturity. For example: although quantum computing is mentioned and has the potential for radical disruptions across industries, its currently low maturity hinders industrial application—similar to brain computer interfaces. Concerning investment decisions, associated i4.0 tech-solutions and technologies are likely to have niche applications and teething issues for the moment. However, in the long-run, they have the potential for disruptive innovations. Complex Systems are an exemption as they represent established technologies that are potentially included in i4.0 tech-solutions despite not being explicitly mentioned in the analysed literature.

Medium frequency of use (14–26 links) this group shows a higher level of technological maturity, which is reflected in a broader tech-solution spectrum. On the long-run, technologies with a medium frequency of use may prove to be both, niche technologies or key enabler for i4.0. Examples include semantic web, cloud manufacturing, and general cloud computing.

High frequency of use (27–39 links) these are used across a variety of i4.0 tech-solutions and have a high maturity, such as AI and CIM/CAx systems. However, these technologies are not always exclusively used for i4.0. From an investment perspective, they highlight promising established technologies with sufficient suppliers and support providers. In addition, they open up a broad application space and future-proof opportunities as they can be used in a multitude of tech-solutions.

In general, technologies with a high frequency can be an indicator of potential i4.0 “base” or “platform” technologies, i.e. technologies that are fundamental prerequisites for any i4.0 tech-solution. Besides CIM/CAX systems and AI, these might include medium frequency technologies such as big data analytics and industrial networks. However, some analysis results are counter-intuitive and need further investigation in the future: this includes the low frequency of social networks, which have great potential for customer or user engagement in the sense of open innovation in the product development phase as well as maintenance or after sales. But this might be due to the focus on manufacturing of i4.0. Another example is mobile internet, which has the potential of a broad application—especially in the context of 5G-eabled fast external and in-factory communication. This might be due to the analysis focus on links stated in literature. It is also important to point out that no specific security technologies were mentioned in the analysed literature despite their critical role for i4.0 (Fuller et al. 2020). Future research needs to explore the underlying reasons. These might include an under-reporting as cyber security technologies could be generic or not i4.0-specific. Given that effective cyber security not only requires technologies but also processes, mechanisms and trainings, a broader analysis scope could be beneficial as well.

5.3 Inherent complexity of Industry 4.0 tech-solutions

The DMM also allows insights into the relative complexity of i4.0 tech-solutions through its row sums. A higher number of required technologies per tech-solution can indicate the associated efforts, such as integrating or managing and maintaining different technology types. Aside from the absolute number of links, their distribution across different technology groups is also relevant. While technologies from one group, such as AI and big data analytics, show large similarities, using technologies from different groups can increase integration efforts and also affect individual innovation cycles, e.g. varying software vs. hardware lifecycles.

Deriving three evenly spaced and whole-numbered groups based on a maximum value of 11, the DMM shows three complexity groups. These involve technologies from at least two technology groups but with no tech-solution using technologies from all seven technology groups:

-

1.

Low complexity (1–4 technologies, usually 2–3 groups)

-

2.

Medium complexity (5–8 technologies, usually around 5 groups)

-

3.

High complexity (9–12 technologies, usually around 6 groups)

In general, the DMM row sums and relative complexities provide an indication of the resulting R&D and implementation efforts, and costs of i4.0 tech-solutions. Highlighting the required technologies for different i4.0 tech-solutions increases the transparency of required preconditions. This supports a well-informed investment decision including a detailed assessment of adoption benefits and risks of specific i4.0 tech-solutions.

5.4 Links between technologies

The i4.0 tech-solution-technology DMM also allows initial insights into dependencies between technologies themselves. Looking at DMM rows of different tech-solutions, patterns of technologies become visible which tend to occur together.

A prominent example is augmented reality, which typically occur in combination with data, (advanced) sensors and simulation. This is reasonable as augmented reality requires AI for sophisticated models and simulations that are projected onto a real-world environment using specific interface technologies like headsets (Alcácer and Cruz-Machado 2019). Similarly, additive manufacturing systems occur in combination with CIM/CAx as such digital models are a prerequisite for the actual manufacturing step (Alcácer and Cruz-Machado 2019). Another example are cobots in combination with advanced sensors to detect humans and objects, or advanced simulation based on CIM/CAx models and AI to enable autonomous and safe collaboration with humans and other machines via industrial networks (Kamble et al. 2018).

A special case are digital twins. These are essential for cyber-physical systems, which are described as a key element of i4.0. Digital twins are sometimes seen as a technology and often used in an ambiguous way as an umbrella term (Murray et al. 2019; Schleich et al. 2017) for what Fuller et al. (2020) differentiate into digital model, digital shadow and actual digital twin. Thus, we do not consider them as a single technology but rather as a group of tech-solutions, which build on use case-specific combinations of technologies, such as computing, data analytics and simulation technologies (Liu et al. 2021).

Although these links between technologies already provide valuable insights into which technologies could or should be combined, enabling and hierarchical dependencies have to be analysed in a next step. This will allow for identifying technology chains and networks and support answering questions like which technologies are required to enable a specific technology. This will enable more technological transparency and contribute to a better understanding and managing of complexity in the context of i4.0 adoption.

5.5 Example application of the i4.0 framework: a cyber-physical i4.0 nano brewery

To answer the question of how the i4.0 tech-solution-technology framework could be used, it was applied to an existing cyber-physical system (CSP), an i4.0 nano-brewery at the University of Technology Sydney in Sydney, Australia (Fig. 3) to conceptually verify it as part of the DRM’s Prescriptive Study (Blessing and Chakrabarti 2009). The brewery’s autonomous process management ensures constant output quality as well as process flexibility and parameter prediction to quickly prototype new recipes. Additional aspects include the upscaling of recipes from lab to industrial scale and the exchange of recipes across global production sites tackling concept drift etc. To address the latter, a partner research institute at the <will be added for accepted publication> possesses an identical physical twin brewery system.

Although the DMM does not specifically list cyber-physical breweries yet, the listed “smart machining” (S4.21) fits well due to its focus on manufacturing and smart processes. “Smart factories” (S4.20) are less suitable due to their focus on an entire socio-technical factory system. The DMM allows the following insights:

The sub-category of Autonomous Equipment is a key aspect for the brewery, which needs to autonomously react to changing ingredients quality like water and malt, and environmental factors such as temperature or humidity, in order to adjust process parameters and ensure a constant beer quality. Other manufacturing technologies like cobots for material handling might be added later but are not part of the core system. An important basis of the brewery is Cloud Computing, in this case, using Amazon Web Services to run RapidMiner AI Hub to analyse process data and build machine learning models to enable an autonomous brewery. Cloud Manufacturing is relevant to share beer recipes between the two global physical twin brewery systems. Although the basis for this is the analysis of big amounts of data, the brewery uses Artificial Intelligence as it does not only include descriptive and diagnostic but also predictive and prescriptive factors. Similar to cobots, advanced human interfaces could be beneficial in the future but are not core element or requirement for the current brewery tech-solution. Due to its encapsulated setup, the brewery does not interact with other manufacturing systems. Thus, Industrial Networks do not apply in this case—despite the DMM entry. Instead, IoT middleware is essential to connect the digital twin components with the underlying different hardware parts of the brewery. This includes actuators, such as valves and heating elements, and traditional sensors, such as temperature and flow sensors, as well as Advanced Sensors, such as electronic nose sensors to assess ingredients and brew quality. However, Computer Integrated Manufacturing along with Factory Management technologies play a minor role for this research brewery—despite the DMM entry—which is mainly due to it being a lab and not an industry brewery line. Nevertheless, they will become important when moving from a lab to an industrial production. This includes upscaling of production volumes and careful management of supplies and logistics to ensure a reliable and economic production.

In respect to the resulting investment decisions when planning such a system, the high column sums of both associated technology sub-categories (Table 2) indicate that this would be a beneficial and future-oriented investment if a company does not have existing CIM or ERP systems. In general, the high row sum indicates a high level of technological complexity of the CPS, which is also reflected in the large variety of required enabling technologies.

From a product development perspective, the DMM can provide guidance around what technology groups will be relevant when designing and developing a new tech-solution. Even though the listed tech-solutions might differ slightly to the one to be developed, it can highlight what might be important, allowing the R&D team to discuss if and how those technologies apply to the new tech-solution. However, the brewery example also showed that some of the listed tech-solutions are more specific than others. Therefore, future research should also investigate how a sub-structure of tech-solution clusters could find a suitable level of abstraction to balance general applicability and level of detail.

In summary, the retrospective application of the i4.0 tech-solution-technology framework to this brewery confirms its conceptual plausibility and usability. It helps validating and sense-checking specific system design decisions of the brewery. In addition, it also indicates aspects that are currently not considered and can therefore trigger a systematic reflection and discussion if and why these aspects might be relevant—right now or in the future.

6 Conclusion

The i4.0 tech-solution-technology DMM framework analyses and highlights dependencies between i4.0 tech-solutions and underlying technologies. This adds transparency to the question of which technologies are required for implementing specific i4.0 tech-solutions. Aside from the dependencies themselves, the i4.0 tech-solution-technology framework also provides initial indications of how frequently specific technologies are used and of the relative complexity of i4.0 tech-solutions. The DMM framework also reveals initial insights into connected technology chains and forms the basis for a future socio-technical analysis.

This research contributes to the field of i4.0 adoption by providing transparency around i4.0 readiness and necessary technological investments to enable specific i4.0 tech-solutions. This includes a systematic analysis and structuring of i4.0 technologies, i4.0 tech-solutions and their interdependencies resulting in an i4.0 tech-solution-technology framework. This is based on a consolidated i4.0 technology taxonomy, which addresses the current issue of varying levels of abstraction of i4.0 in literature. It provides a clear structure and categorization considering different levels of abstraction. The combined product development and manufacturing perspectives of i4.0 tech-solutions are a first step in broadening the scope from an originally manufacturing concept to a holistic lifecycle-spanning consideration and application of i4.0. This adds to developing an in-depth understanding and definition of i4.0 (Hermann et al. 2016; Klingenberg et al. 2021; Lu 2017). In addition, the DMM analysis provides the basis for future analysis of tech-solution-technology dependencies, of technology-technology interdependencies and a systems-thinking angle for analysing adoption barriers. This can serve as a basis for developing methodical i4.0 strategy and implementation guidelines for companies, as demanded by Abdirad and Krishnan (2021).

These will also be of high relevance to industry in the medium-term future. In the short-run, industry benefits through a systematic overview of which technologies are required for specific i4.0 tech-solutions and which technologies are i4.0 key enablers. This reduces the risk of missing necessary technologies and supports well-informed investment decisions. The DMM framework also provides indications on general technological maturity risks as well as which technologies allow for a large variety of tech-solutions and resulting opportunities. However, it is important to note that these frequencies of use are from an i4.0 perspective: so, for instance, Social Networks might only be a niche technology for i4.0 tech-solutions but become more relevant when broadening the scope to other perspectives, such as open innovation. Thus, for a holistic view, companies will also need to consider other technology adoption strategies beyond i4.0.

Despite these contributions, it is vital to discuss limitations and resulting potential for further research. Although the case study proves to be useful in conceptually verifying the framework as part of the DRM’s Prescriptive Study (Blessing and Chakrabarti 2009), it needs to be broadly applied and evaluated in different industry projects to prospectively plan and accompany the adoption of different i4.0 tech-solutions as part of an in-depth DRM’s Descriptive Study 2. While this provides direct support to these projects, it also allows to iteratively evaluate and empirically refine the currently conceptual framework in different industry settings. A practical evaluation of the framework could be conducted in two groups per i4.0 adoption project: one group planning the implementation of i4.0 tech-solution and required technological investments without and one group using the framework. This allows for a comparison of e.g. understanding of technological complexity, investment decisions and effort as well as quality of the decision-making process.

Another limitation that the case study showed is that framework users, such as technology and production managers, currently need to manually allocate a new tech-solution to one of the listed ones, which act as a proxy in the DMM. As tech-solutions have a similar dynamic evolution as technologies, it is necessary to explore how a suitable tech-solution taxonomy could be structured. Finding the right balance between level of details and general applicability will be key. A potential way forward could be to cluster them according to their technology links in the DMM. However, this could cause issues regarding the alignment with the product generation process. Although the rather rough clustering in four process phases (Schneider et al. 2020) worked well in this case, the phases could be detailed further to provide more orientation in different settings.

A minor limitation is the current focus on i4.0 technology review articles. For the DMM, this is sufficient as the three-level technology taxonomy uses its middle-level categories for the mapping onto tech-solutions, which allows for independence from specific single technologies. While this allows for a time-robust DMM mapping, the analysis of single technology papers could add further hitherto implicit insights. In case of new radically different technologies, an additional middle category could be added to the technology taxonomy. This will also be necessary to enhance the current top-level category of cyber-security.

Concerning a detailed future i4.0 adoption support, the current DMM framework only highlights which technologies are required for specific i4.0 tech-solutions. However, it does not indicate a suitable adoption sequence. In this respect, an additional hierarchical perspective on i4.0 technologies, such as Lee et al. (2015), could be helpful in prioritising and sequencing the adoption of different required technologies. In addition, the current DMM lacks an analysis of inter-technology dependencies. Thus, future research also needs to investigate how technologies are depending on each other, for instance, in the sense or enabling prerequisites, which would also support in prioritising the adoption of specific technologies.

However, such a technology analysis is not sufficient due to the socio-technical character of i4.0 (Pedota et al. 2023). Instead, future research needs to broaden its scope beyond technologies and also include competences, skill, organizational processes, business models, and mindsets and organisational culture. This will be crucial from an organisational change management perspective and to ensure a successful long-term use of new i4.0 socio-technical capabilities. This includes data security and privacy and its socio-technical impact as well as mitigation measures (Bajic et al. 2021; Yu and Schweisfurth 2020).

References

Abdirad M, Krishnan K (2021) Industry 4.0 in logistics and supply chain management: a systematic literature review. Eng Manag J 33(3):187–201

Agostini L, Nosella A (2020) The adoption of Industry 4.0 technologies in SMEs: results of an international study. Manag Decis 58(4):625–643

Ahuett-Garza H, Kurfess T (2018) A brief discussion on the trends of habilitating technologies for Industry 4.0 and smart manufacturing. Manuf Lett 15:60–63

Alcácer V, Cruz-Machado V (2019) Scanning the Industry 4.0: a literature review on technologies for manufacturing systems. Eng Sci Technol Int J 22(3):899–919

Alladi T, Chamola V, Parizi RM, Choo K-KR (2019) Blockchain applications for Industry 4.0 and industrial IoT: a review. IEEE Access 7:176935–176951

Arromba IF, Martin PS, Cooper Ordoñez R, Anholon R, Rampasso IS, Santa-Eulalia LA, Martins VWB, Quelhas OLG (2021) Industry 4.0 in the product development process: benefits, difficulties and its impact in marketing strategies and operations. J Bus Ind Market 36(3):522–534

Bag S, Pretorius JHC (2022) Relationships between Industry 4.0, sustainable manufacturing and circular economy: proposal of a research framework. Int J Organ Anal 30(4):864–898

Bajic B, Rikalovic A, Suzic N, Piuri V (2021) Industry 4.0 implementation challenges and opportunities: a managerial perspective. IEEE Syst J 15(1):546–559

Bauer W, Schlund S, Marrenbach DH, Ganschar O (2014) Industrie 4.0 - Volkswirtschaftliches Potenzial für Deutschland. Controlling 27:515–517

Bauernhansl T, ten Hompel M, Vogel-Heuser B (2014) Industrie 4.0 in Produktion, Automatisierung und Logistik. Springer Fachmedien Wiesbaden, Wiesbaden

Betz F (2011) Managing technological innovation: Competitive advantage from change, 3rd edn. Wiley, Hoboken

Bittencourt VL, Alves AC, Leão CP (2019) Lean thinking contributions for Industry 4.0: a systematic literature review. IFAC-PapersOnLine 52(13):904–909

Bittighofer D, Dust M, Irslinger A, Liebich M, Martin L (2018) State of Industry 4.0 across German companies. In: 2018 IEEE international conference on engineering, technology and innovation (ICE/ITMC). Stuttgart, 17/06/2018–20/06/2018, IEEE, pp 1–8

Blessing LT, Chakrabarti A (2009) DRM, a design research methodology. Springer, Heidelberg

Bodkhe U, Tanwar S, Parekh K, Khanpara P, Tyagi S, Kumar N, Alazab M (2020) Blockchain for Industry 4.0: a comprehensive review. IEEE Access 8:79764–79800

Bongomin O, Gilibrays Ocen G, Oyondi Nganyi E, Musinguzi A, Omara T (2020) Exponential disruptive technologies and the required skills of Industry 4.0. J Eng 2020:1–17

Browning TR (2016) Design structure matrix extensions and innovations: a survey and new opportunities. IEEE Trans Eng Manag 63(1):27–52

Bueno A, Godinho Filho M, Frank AG (2020) Smart production planning and control in the Industry 4.0 context: a systematic literature review. Comput Ind Eng 149:106774

Calabrese A, Dora M, Levialdi Ghiron N, Tiburzi L (2020) Industry’s 4.0 transformation process: how to start, where to aim, what to be aware of. Prod Plann Control 33(5):492–512

Calabrese A, Levialdi Ghiron N, Tiburzi L (2021) ‘Evolutions’ and ‘revolutions’ in manufacturers’ implementation of Industry 4.0: a literature review, a multiple case study, and a conceptual framework. Prod Plan Control 32(3):213–227

Chen Y (2017) Integrated and intelligent manufacturing: perspectives and enablers. Engineering 3(5):588–595

Chen Y, Yang O, Sampat C, Bhalode P, Ramachandran R, Ierapetritou M (2020) Digital twins in pharmaceutical and biopharmaceutical manufacturing: a literature review. Processes 8(9):1088

Cherubini A, Passama R, Crosnier A, Lasnier A, Fraisse P (2016) Collaborative manufacturing with physical human–robot interaction. Robot Comput Integr Manuf 40:1–13

Cotrino A, Sebastián MA, González-Gaya C (2020) Industry 4.0 roadmap: implementation for small and medium-sized enterprises. Appl Sci 10(23):8566

Dalmarco G, Ramalho FR, Barros AC, Soares AL (2019) Providing Industry 4.0 technologies: the case of a production technology cluster. J High Technol Manag Res 30(2):100355

Danilovic M, Browning TR (2007) Managing complex product development projects with design structure matrices and domain mapping matrices. Int J Project Manag 25(3):300–314

Danilovic M, Sandkull B (2005) The use of dependence structure matrix and domain mapping matrix in managing uncertainty in multiple project situations. Int J Project Manage 23(3):193–203

de Paula Ferreira W, Armellini F, de Santa-Eulalia LA (2020) Simulation in Industry 4.0: a state-of-the-art review. Comput Ind Eng 149:106868

Dombrowski U, Richter T, Krenkel P (2017) Interdependencies of Industrie 4.0 & lean production systems: a use cases analysis. Procedia Manuf 11:1061–1068

Erol S, Schumacher A, Sihn W (2016) Strategic guidance towards Industry 4.0—a three-stage process model. In: International conference on competitive manufacturing 2016 (COMA’16). Stellenbosch, South Africa

Faller C, Feldmüller D (2015) Industry 4.0 learning factory for regional SMEs. Procedia CIRP 32:88–91

Fatorachian H, Kazemi H (2021) Impact of Industry 4.0 on supply chain performance. Prod Plan Control 32(1):63–81

Feldman LP, Page AL (1984) Principles vs. practice in new product planning. J Prod Innov Manag 1(1):43–55

Fernandez-Carames TM, Fraga-Lamas P (2019) A review on the application of blockchain to the next generation of cybersecure Industry 4.0 smart factories. IEEE Access 7:45201–45218

Firmino AS, Perles GX, Mendes JV, Da Silva JEAR, Silva DAL (2020) Towards industry 40: a SWOT-based analysis for companies located in the Sorocaba Metropolitan Region (São Paulo State, Brazil). Gestão Produção. https://doi.org/10.1590/0104-530x5622-20

Fraga-Lamas P, Fernandez-Carames TM (2019) A review on blockchain technologies for an advanced and cyber-resilient automotive industry. IEEE Access 7:17578–17598

Fraga-Lamas P, Fernandez-Carames TM, Blanco-Novoa O, Vilar-Montesinos MA (2018) A review on industrial augmented reality systems for the Industry 4.0 shipyard. IEEE Access 6:13358–13375

Frank AG, Dalenogare LS, Ayala NF (2019) Industry 4.0 technologies: implementation patterns in manufacturing companies. Int J Prod Econ 210:15–26

Fuller A, Fan Z, Day C, Barlow C (2020) Digital twin: enabling technologies, challenges and open research. IEEE Access 8:108952–108971

García JI, Cano RE, Contreras JD (2020) Digital retrofit: a first step toward the adoption of Industry 4.0 to the manufacturing systems of small and medium-sized enterprises. Proc Inst Mech Eng Part B J Eng Manuf 234(8):1156–1169

Gartner (2022) Definition of solution—Gartner information technology glossary. https://www.gartner.com/en/information-technology/glossary/solution. Accessed 1 Oct 2022

Ghobakhloo M (2018) The future of manufacturing industry: a strategic roadmap toward Industry 4.0. J Manuf Technol Manag 29(6):910–936

Ghobakhloo M (2020) Industry 4.0, digitization, and opportunities for sustainability. J Clean Prod 252:119869

Ghobakhloo M, Iranmanesh M, Vilkas M, Grybauskas A, Amran A (2022) Drivers and barriers of Industry 4.0 technology adoption among manufacturing SMEs: a systematic review and transformation roadmap. J Manuf Technol Manag 33(6):1029–1058

Gochermann J (2022) Technology management: recognizing, evaluating and successfully using technologies. Springer, Wiesbaden

Govindarajan UH, Trappey AJC, Trappey CV (2018) Immersive technology for human-centric cyberphysical systems in complex manufacturing processes: a comprehensive overview of the global patent profile using collective intelligence. Complexity 2018:1–17

Gualtieri L, Rauch E, Vidoni R (2021) Emerging research fields in safety and ergonomics in industrial collaborative robotics: a systematic literature review. Robot Comput Integr Manuf 67:101998

Gupta A, Basu B (2019) Sustainable primary aluminium production: technology status and future opportunities. Trans Indian Inst Met 72(8):2135–2150

Hermann M, Pentek T, Otto B (2016) Design principles for industrie 4.0 scenarios. In: 2016 49th Hawaii international conference on system sciences (HICSS). Koloa, HI, USA, 05/01/2016–08/01/2016. IEEE, pp 3928–3937

Hoffmann Souza ML, Da Costa CA, de Oliveira Ramos G, Da Rosa Righi R (2020) A survey on decision-making based on system reliability in the context of Industry 4.0. J Manuf Syst 56:133–156

İç YT (2012) An experimental design approach using TOPSIS method for the selection of computer-integrated manufacturing technologies. Robot Comput Integr Manuf 28(2):245–256

Inkermann D, Schneider D, Martin NL, Lembeck H, Zhang J, Thiede S (2019) A framework to classify Industry 4.0 technologies across production and product development. Procedia CIRP 84:973–978

Javaid M, Haleem A, Vaishya R, Bahl S, Suman R, Vaish A (2020) Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes Metab Syndrome 14(4):419–422

Jiang Z, Yuan S, Ma J, Wang Q (2022) The evolution of production scheduling from Industry 3.0 through Industry 4.0. Int J Prod Res 60(11):3534–3554

Kagermann H (2015) Change through digitization—value creation in the age of Industry 4.0. In: Albach H, Meffert H, Pinkwart A, Reichwald R (eds) Management of permanent change. Springer Fachmedien Wiesbaden, Wiesbaden, pp 23–45

Kamble SS, Gunasekaran A, Gawankar SA (2018) sustainable Industry 4.0 framework: a systematic literature review identifying the current trends and future perspectives. Process Saf Environ Prot 117:408–425

Kang HS, Lee JY, Choi S, Kim H, Park JH, Son JY, Kim BH, Noh SD (2016) Smart manufacturing: past research, present findings, and future directions. Int J Precis Eng Manuf Green Technol 3(1):111–128

Kannan KSP, Garad A (2021) Competencies of quality professionals in the era of Industry 4.0: a case study of electronics manufacturer from Malaysia. Int J Qual Reliabil Manag 38(3):839–871

Kerin M, Pham DT (2019) A review of emerging Industry 4.0 technologies in remanufacturing. J Clean Prod 237:117805

Khaitan SK, McCalley JD (2015) Design techniques and applications of cyberphysical systems: a survey. IEEE Syst J 9(2):350–365

Klingenberg CO, Borges MAV, Antunes JAV Jr (2021) Industry 4.0 as a data-driven paradigm: a systematic literature review on technologies. J Manuf Technol Manag 32(3):570–592

Kumar A (2018) Methods and materials for smart manufacturing: additive manufacturing, internet of things, flexible sensors and soft robotics. Manuf Lett 15:122–125

Kumar S, Suhaib M, Asjad M (2020) Industry 4.0: complex, disruptive, but inevitable. Manag Prod Eng Rev 11:43–51

Lasi H, Fettke P, Kemper H-G, Feld T, Hoffmann M (2014) Industry 4.0. Bus Inf Syst Eng 6(4):239–242

Lee J, Bagheri B, Kao H-A (2015) A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manuf Lett 3:18–23

Levy Y, Ellis TJ (2006) A systems approach to conduct an effective literature review in support of information systems research. Inf Sci Int J Emerg Transdiscip 9:181–212

Li L, Chi T, Hao T, Yu T (2018) Customer demand analysis of the electronic commerce supply chain using big data. Ann Oper Res 268(1–2):113–128

Liao Y, Deschamps F, Loures EDFR, Ramos LFP (2017) Past, present and future of Industry 4.0—a systematic literature review and research agenda proposal. Int J Prod Res 55(12):3609–3629

Lim CH, Lim S, How BS, Ng WPQ, Ngan SL, Leong WD, Lam HL (2021) A review of Industry 4.0 revolution potential in a sustainable and renewable palm oil industry: HAZOP approach. Renew Sustain Energy Rev 135:110223

Liu M, Fang S, Dong H, Xu C (2021) Review of digital twin about concepts, technologies, and industrial applications. J Manuf Syst 58:346–361

Lopez-Gomez C, Leal-Ayala D, Palladino M, O'Sullivan E (2017) Emerging trends in global advanced manufacturing: challenges, opportunities and policy responses. https://www.ciip-group.org/reports-and-articles/emerging-trends-global-advanced-manufacturing-chal/.

Lu Y (2017) Industry 4.0: a survey on technologies, applications and open research issues. J Ind Inf Integr 6:1–10

Marri HB, Gunasekaran A, Grieve RJ (1998) An investigation into the implementation of computer integrated manufacturing in small and medium enterprises. Int J Adv Manuf Technol 14(12):935–942

Martín-Martín A, Orduna-Malea E, Thelwall M, Delgado López-Cózar E (2018) Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J Informetr 12(4):1160–1177

Modrák V, Mandul’ák J (2009) Mapping development of mes functionalities. In: Proceedings of the 6th international conference on informatics in control, automation and robotics. Milan, Italy, 02/07/2009–05/07/2009, SciTePress - Science and and Technology Publications, pp 244–247

Moher D, Liberati A, Tetzlaff J, Altman DG (2009) Preferred reporting items for systematic reviews and meta-analyses: the PRISMA statement. PLoS Med 6(7):e1000097

Moldabekova A, Zhidebekkyzy A, Baimukhanbetova E, Akhmetkaliyeva S (2020) Advanced technologies in improving the management of logistics services: bibliometric network analysis. Polish J Manag Stud 21(1):211–223

Morales GAG, Nizamis K, Bonnema GM (2023) Engineering complexity beyond the surface: discerning the viewpoints, the drivers, and the challenges. Res Eng Des. https://doi.org/10.1007/s00163-023-00411-9

Müller JM, Buliga O, Voigt K-I (2018) Fortune favors the prepared: how SMEs approach business model innovations in industry 4.0. Technol Forecast Soc Chang 132:2–17

Munsamy M, Telukdarie A, Dhamija P (2020) Logistics 4.0 energy modelling. Int J Bus Anal 7(1):98–121

Murray P, Wattis Z, Bain B, Golowczynski M, Sadd A (2019) Towards a digital twin supporting risk based decision making for offshore installations. In: Society of Petroleum Engineers—SPE Offshore Europe conference and exhibition 2019, OE 2019. Aberdeen, UK, 03/09/2019–06/09/2019

Naefe P, Luderich J (2016) Konstruktionsmethodik für die Praxis. Springer Fachmedien Wiesbaden, Wiesbaden

Nascimento DLM, Alencastro V, Quelhas OLG, Caiado RGG, Garza-Reyes JA, Rocha-Lona L, Tortorella G (2019) Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J Manuf Technol Manag 30(3):607–627

Nosalska K, Piątek ZM, Mazurek G, Rządca R (2020) Industry 4.0: coherent definition framework with technological and organizational interdependencies. J Manuf Technol Manag 31(5):837–862

Núñez-Merino M, Maqueira-Marín JM, Moyano-Fuentes J, Martínez-Jurado PJ (2020) Information and digital technologies of Industry 4.0 and lean supply chain management: a systematic literature review. Int J Prod Res 58(16):5034–5061

Orzes G, Poklemba R, Towner WT (2020) Implementing Industry 4.0 in SMEs: a focus group study on organizational requirements. In: Matt DT, Modrák V, Zsifkovits H (eds) Industry 4.0 for SMEs. Springer International Publishing, Cham, pp 251–277

Ottogalli R, Amundarain A, Borro (2019) Flexible framework to model Industry 4.0 processes for virtual simulators. Appl Sci 9(23):4983

Oztemel E, Gursev S (2020) Literature review of Industry 4.0 and related technologies. J Intell Manuf 31(1):127–182

Pacchini APT, Lucato WC, Facchini F, Mummolo G (2019) The degree of readiness for the implementation of Industry 4.0. Comput Ind 113:103125

Pedota M, Grilli L, Piscitello L (2023) Technology adoption and upskilling in the wake of Industry 4.0. Technol Forecast Soc Change 187:122085

Polojärvi D, Palmer E, Dunford C (2023) A systematic literature review of sociotechnical systems in systems engineering. Syst Eng 26(4):482–504

Raj A, Dwivedi G, Sharma A, de Sousa L, Jabbour AB, Rajak S (2020) Barriers to the adoption of Industry 4.0 technologies in the manufacturing sector: an inter-country comparative perspective. Int J Prod Econ 224:107546

Ramírez-Durán VJ, Berges I, Illarramendi A (2021) Towards the implementation of Industry 4.0: a methodology-based approach oriented to the customer life cycle. Comput Ind 126:103403

Ramirez-Peña M, Abad Fraga FJ, Salguero J, Batista M (2020) Assessing sustainability in the shipbuilding supply chain 4.0: a systematic review. Sustainability 12(16):6373

Santos RC, Martinho JL (2020) An Industry 4.0 maturity model proposal. J Manuf Technol Manag 31(5):1023–1043

Schleich B, Anwer N, Mathieu L, Wartzack S (2017) Shaping the digital twin for design and production engineering. CIRP Ann Manuf Technol 66(1):141–144

Schneider D, Fröhlich T, Huth T, Vietor T (2020) Design for flexibility—evaluation interactions between product properties and production processes. Procedia CIRP 91:814–818

Schneider D, Huth T, Vietor T (2021) Development of an Industry 4.0 method and knowledge platform for strategic technology implementation. Procedia CIRP 100:613–618

Schott P, Lederer M, Eigner I, Bodendorf F (2020) Case-based reasoning for complexity management in Industry 4.0. J Manuf Technol Manag 31(5):999–1021

Shahin M, Chen FF, Bouzary H, Krishnaiyer K (2020) Integration of lean practices and Industry 4.0 technologies: smart manufacturing for next-generation enterprises. Int J Adv Manuf Technol 107(5–6):2927–2936

Shi Z, Xie Y, Xue W, Chen Y, Fu L, Xu X (2020) Smart factory in Industry 4.0. Syst Res Behav Sci 37(4):607–617

Sittón-Candanedo I, Alonso RS, Corchado JM, Rodríguez-González S, Casado-Vara R (2019) A review of edge computing reference architectures and a new global edge proposal. Future Gener Comput Syst 99:278–294

Strange R, Zucchella A (2017) Industry 4.0, global value chains and international business. Multinatl Bus Rev 25(3):174–184

Szalavetz A (2017) The environmental impact of advanced manufacturing technologies: examples from Hungary. Cent Eur Bus Rev 6(2):18–29

Szász L, Demeter K, Rácz B-G, Losonci D (2021) Industry 4.0: a review and analysis of contingency and performance effects. J Manuf Technol Manag 32(3):667–694

Vielhaber M, Stoffels P (2014) Product development vs production development. Procedia CIRP 21:252–257

Volkwein M, Schmitt J, Heidelbach J, Schöllhammer O, Evcenko D, Kett H (2022) Blinde Flecken in der Umsetzung von Industrie 4.0—identifizieren und verstehen

Wagner T, Herrmann C, Thiede S (2017) Industry 4.0 impacts on lean production systems. Procedia CIRP 63:125–131

Wichmann RL, Eisenbart B, Gericke K (2019) The direction of industry: a literature review on Industry 4.0. Proc Des Soc Int Conf Eng Des 1(1):2129–2138

Wijewardhana GEH, Weerabahu SK, Nanayakkara JLD, Samaranayake P (2021) New product development process in apparel industry using Industry 4.0 technologies. Int J Product Perform Manag 70(8):2352–2373

Wohlin C (2014) Guidelines for snowballing in systematic literature studies and a replication in software engineering. In: Proceedings of the 18th international conference on evaluation and assessment in software engineering—EASE '14. London, England, United Kingdom, 13/05/2014–14/05/2014. ACM Press, New York, NY, USA, pp 1–10