Abstract

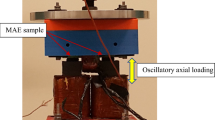

The paper presents an experimental study and numerical simulation of stress relaxation behavior of isotropic and anisotropic magnetorheological elastomers (MREs) made from silicone rubber filled with micro-sized carbonyl iron powder. Effects of applied constant strains and magnetic fields of an electromagnet on the stress relaxation of the MREs were investigated for 10 h using the single relaxation test with double-lap shear samples. The isotropic MRE showed a linearly elastic behavior, while the anisotropic MRE indicated a highly nonlinear elastic response. The shear stress and relaxation modulus of anisotropic MRE are much higher than those of isotropic MRE. The shear stress of the MREs increased with increasing the constant strain, while their relaxation modulus decreased. The shear stress and relaxation modulus of the MREs within the first 0.25 h boosted with raising the magnetic flux density to about 0.5 T. However, the shear stress and relaxation modulus of the MREs under strong magnetic fields declined considerably after 0.25 h testing. This reduction was attributed to the temperature rise in the MRE samples caused by the heating of the electromagnet. The stress relaxation behavior of the MREs was examined using a four-parameter fractional derivative model. The model parameters were obtained by fitting the relaxation modulus to the measured data of the MREs. The shear stress and relaxation modulus with long-term predictions estimated from the studied model were in good agreement with the measured data for the MREs at various applied strains and under low magnetic fields. The model-predicted values did not agree well with the experimental data of the MREs under high magnetic fields because of the sample temperature gain caused by heat generation of the electromagnet. Therefore, the investigated model can be used to predict the long-term relaxation stress of the MREs under high magnetic fields of permanent magnets.

Similar content being viewed by others

References

Rigbi, Z., Jilken, L.: The response of an elastomer filled with soft ferrite to mechanical and magnetic influences. J. Magn. Magn. Mater. 37(3), 267–276 (1983)

Ahamed, R., Choi, S.B., Ferdaus, M.M.: A state of art on magneto-rheological materials and their potential applications. J. Intell. Mater. Syst. Struct. 29(10), 2051–2095 (2018)

Bastola, A.K., Hossain, H.: A review on magneto-mechanical characterizations of magnetorheological elastomers. Compos. B. Eng. 200, 108348 (2020)

Bastola, A.K., Paudel, M., Li, L., Li, W.: Recent progress of magnetorheological elastomers: a review. Smart Mater. Struct. 29, 123002 (2020)

Díez, A.G., Tubio, C.R., Etxebarria, J.G., Lanceros-Mendez, S.: Magnetorheological elastomer-based materials and devices: state of the art and future perspectives. Adv. Eng. Mater. 23(6), 2100240 (2021)

Bastola, A.K., Hossain, M.: The shape-morphing performance of magnetoactive soft materials. Mater. Des. 211, 110172 (2021)

Lucarini, S., Hossain, M., Garcia-Gonzalez, D.: Recent advances in hard-magnetic soft composites: synthesis, characterisation, computational modelling, and applications. Compos. Struct. 279, 114800 (2022)

Deng, H.X., Gong, X.L.: Application of magnetorheological elastomer to vibration absorber. Commun. Nonlinear Sci. Numer. Simul. 13, 1938–1947 (2008)

Kumbhar, S.B., Chavan, S.P., Gawade, S.S.: Adaptive tuned vibration absorber based on magnetorheological elastomer-shape memory alloy composite. Mech. Syst. Signal Process. 100, 208–223 (2018)

Gao, P., Liu, H., Xiang, C., Yan, P., Mahmoud, T.: A new magnetorheological elastomer torsional vibration absorber: structural design and performance test. Mech. Sci. 12(1), 321–332 (2021). https://doi.org/10.5194/ms-12-321-2021

Liao, G.J., Gong, X., Xuan, S.H., Kang, C.J., Zong, L.H.: Development of a real-time tunable stiffness and damping vibration isolator based on magnetorheological elastomer. J. Intell. Mater. Syst. Struct. 23, 25–33 (2012)

Bastola, A.K., Li, L.: A new type of vibration isolator based on magnetorheological elastomer. Mater. Des. 157, 431–436 (2018)

Liu, S., Feng, L., Zhao, D., Shi, X., Zhang, Y., Jiang, J., et al.: A real-time controllable electromagnetic vibration isolator based on magnetorheological elastomer with quasi-zero stiffness characteristic. Smart Mater. Struct. 28(8), 085037 (2019)

Qi, S., Guo, H., Chen, J., Fu, J., Hu, C., Yu, M., Wang, Z.L.: Magnetorheological elastomers enabled high-sensitive self-powered tribo-sensor for magnetic field detection. Nanoscale 10(10), 4745–4752 (2018)

Hu, T., Xuan, S., Ding, L., Gong, X.: Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater. Des. 156, 528–537 (2018)

Böse, H., Gerlach, T., Ehrlich, J.: Magnetorheological elastomers: an underestimated class of soft actuator materials. J. Intell. Mater. Syst. Struct. 32(14), 1550–1564 (2021)

Wu, C., Zhang, Q., Fan, X., Song, Y., Zheng, Q.: Smart magnetorheological elastomer peristaltic pump. J. Intell. Mater. Syst. Struct. 30(7), 1084–1093 (2019)

Lapipo, I.L., Fadly, J.D., Faris, W.F.: Characterization of magnetorheological elastomer (MRE) engine mounts. Mater. Today: Proc. 3, 411–418 (2016)

Lapine, M., Shadrivov, I.V., Powell, D.A., Kivshar, Y.S.: Magnetoelastic metamaterials. Nat. Mater. 11(1), 30–33 (2012)

Harne, R.L., Deng, Z., Dapino, M.J.: Adaptive magnetoelastic metamaterials: a new class of magnetorheological elastomers. J. Intell. Mater. Syst. Struct. 29(2), 265–278 (2018)

Maraghechi, S., Hoefnagels, J.P.M., Peerlings, R.H.J., Rokoš, O., Geers, M.G.: Experimental full-field analysis of size effects in miniaturized cellular elastomeric metamaterials. Mater. Des. 193, 108684 (2020)

Li, Y., Li, J., Tian, T., Li, W.: A highly adjustable magnetorheological elastomer base isolator for applications of real-time adaptive control. Smart Mater. Struct. 22, 095020 (2013)

Testa, P., Style, R.W., Cui, J., Donnelly, C., Borisova, E., Derlet, P.M., Dufresne, E.R., Heyderman, L.J.: Magnetically addressable shape-memory and stiffening in a composite elastomer. Adv. Mater. 31(29), 1900561 (2019)

Wu, S., Hu, W., Ze, Q., Sitti, M., Zhao, R.: Multifunctional magnetic soft composites: a review. Multifunct. Mater. 3, 042003 (2020)

Bira, N., Dhagat, P., Davidson, J.R.: A review of magnetic elastomers and their role in soft robotics. Front. Robot. AI 7, 146 (2020)

Chen, L., Gong, X.L., Jiang, W.Q., Yao, J.J., Deng, H.X., Li, W.H.: Investigation on magnetorheological elastomers based on natural rubber. J. Mater. Sci. 42(14), 5483–5489 (2007)

Shit, S.C., Shah, P.: A review on silicone rubber. Natl. Acad. Sci. Lett. 36(4), 355–365 (2013)

Cvek, M., Kracalik, M., Sedlacik, M., Mrlik, M., Sedlarik, V.: Reprocessing of injection molded magnetorheological elastomers based on TPE matrix. Compos. B. Eng. 172, 253–261 (2019)

Li, Y., Li, J., Li, W., Du, H.: A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 23(12), 123001 (2014)

Sutrisno, J., Purwanto, A., Mazlan, S.A.: Recent progress on magnetorheological solids: materials, fabrication, testing, and applications. Adv. Eng. Mater. 17(5), 563–597 (2015)

Nam, T.H., Petríková, I., Marvalová, B.: Experimental characterization and viscoelastic modeling of isotropic and anisotropic magnetorheological elastomers. Polym. Test. 81, 106272 (2020)

Nam, T.H., Petríková, I., Marvalová, B.: Experimental and numerical research of stress relaxation behavior of magnetorheological elastomer. Polym. Test. 93, 106886 (2021)

Nam, T.H., Petríková, I., Marvalová, B.: Effects of loading rate, applied shear strain, and magnetic field on stress relaxation behavior of anisotropic magnetorheological elastomer. Mech. Adv. Mater. Struct. (2021). https://doi.org/10.1080/15376494.2021.1883162

Amin, A.F.M.S., Lion, A., Sekita, S., Okui, Y.: Nonlinear dependence of viscosity in modeling the rate-dependent response of natural and high damping rubbers in compression and shear: Experimental identification and numerical verification. Int. J. Plast. 22, 1610–1657 (2006)

Wang, L., Han, Y.: Compressive relaxation of the stress and resistance for carbon nanotube filled silicone rubber composite. Compos. Part A Appl. Sci. Manuf. 47, 63–71 (2013)

Sahu, R., Patra, K., Szpunar, J.: Experimental study and numerical modelling of creep and stress relaxation of dielectric elastomers. Strain 51, 43–54 (2015)

Yamaguchi, K., Thomas, A.G., Busfield, J.J.: Stress relaxation, creep and set recovery of elastomers. Int. J. Non-Linear Mech. 68, 66–70 (2015)

Qi, S., Yu, M., Fu, J., Zhu, M.: Stress relaxation behavior of magnetorheological elastomer: experimental and modeling study. J. Intell. Mater. Syst. Struct. 29, 205–213 (2018)

Fan, Y., Qin, H., Lu, C., Liao, C., Chen, X., Yu, J., Xie, L.: Capacitance creep and recovery behavior of magnetorheological elastomers. J. Intell. Mater. Syst. Struct. 32(13), 1420–1431 (2021)

Johari, M.A.F., Mazlan, S.A., Nordin, N.A., Aziz, S.A.A., Johari, N., Nazmi, N., Homma, K.: Shear band formation in magnetorheological elastomer under stress relaxation. Smart Mater. Struct. 30(4), 045015 (2021)

Rey, T., Chagnon, G., Cam, J.B.L., Favier, D.: Influence of the temperature on the mechanical behavior of filled and unfilled silicone rubbers. Polym. Test. 32(3), 492–501 (2013)

Laurent, H., Rio, G., Vandenbroucke, A., Hocine, N.A.: Experimental and numerical study on the temperature-dependent behavior of a fluoro-elastomer. Mech. Time-Depend. Mater. 18(4), 721–742 (2014)

Dippel, B., Johlitz, M., Lion, A.: Thermo-mechanical couplings in elastomers-experiments and modelling. Z. Angew. Math. Mech. 95(11), 1117–1128 (2015). https://doi.org/10.1002/zamm.201400110

Wan, Y., Xiong, Y., Zhang, S.: Temperature dependent dynamic mechanical properties of magnetorheological elastomers: experiment and modeling. Compos. Struct. 202, 768–773 (2018)

Wen, Q., Shen, L., Li, J., Xuan, S., Li, Z., Fan, X., Li, B., Gong, X.: Temperature dependent magneto-mechanical properties of magnetorheological elastomers. J. Magn. Magn. Mater. 497, 165998 (2020)

Mainardi, F.: Fractional Calculus and Waves in Linear Viscoelasticity: An Introduction to Mathematical Models. Imperial College Press, London (2010)

Nadzharyan, T.A., Kostrov, S.A., Stepanov, G.V., Kramarenko, E.Y.: Fractional rheological models of dynamic mechanical behavior of magnetoactive elastomers in magnetic fields. Polymer 142, 316–329 (2018)

Bonfanti, A., Kaplan, J.L., Charras, G., Kabla, A.: Fractional viscoelastic models for power-law materials. Soft Matter 16(26), 6002–6020 (2020)

Shen, L.J.: Fractional derivative models for viscoelastic materials at finite deformations. Int. J. Solids Struct. 190, 226–237 (2020)

Su, X., Yao, D., Xu, W.: Processing of viscoelastic data via a generalized fractional model. Int. J. Eng. Sci. 161, 103465 (2021)

Guo, X., Yan, G., Benyahia, L., Sahraoui, S.: Fitting stress relaxation experiments with fractional Zener model to predict high frequency moduli of polymeric acoustic foams. Mech. Time-Depend. Mater. 20(4), 523–533 (2016)

Guo, Q., Zaïri, F., Guo, X.: A thermo-viscoelastic-damage constitutive model for cyclically loaded rubbers. Part II: experimental studies and parameter identification. Int. J. Plast. 101, 58–73 (2018)

Acknowledgements

This work was supported by the Ministry of Education, Youth and Sports of the Czech Republic and the European Union - European Structural and Investment Funds in the frames of Operational Program Research, Development and Education -Project Hybrid Materials for Hierarchical Structures (HyHi, Reg. No. CZ.02.1.01/0.0/0.0/16_019/0000843).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nam, T.H., Petríková, I. & Marvalová, B. Stress relaxation behavior of isotropic and anisotropic magnetorheological elastomers. Continuum Mech. Thermodyn. 36, 299–315 (2024). https://doi.org/10.1007/s00161-022-01097-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-022-01097-5