Abstract

This work presents studies on static aeroelastic shape optimization of aircraft wings subject to large deformations. The physics are captured using a coupled 3D panel method and a nonlinear co-rotating beam finite element model. The wing is defined by a series of airfoils that are parameterized based on the definition of NACA 4-digit airfoils. The method assumes a solid cross section of isotropic material which is representative of foam core wings. Analytic expressions are derived for most of the cross-sectional stiffness properties, while approximations are introduced for the location of the shear center and the torsional stiffness. Optimized designs achieved using linear and nonlinear deformation models are compared and features are discussed. The objective is to minimize drag subject to constraints on geometry, tip displacement, and root bending moment. Results highlight the importance of using nonlinear models to accurately capture changes in wingspan due to large deformations, as even small differences in the wingspan can have a large effect on the induced drag. Non-planar wings with raised and drooped wingtips are also optimized, where drooped wings are found to achieve larger lift-to-drag ratios due to the increase in effective wingspan in the deformed configuration.

Similar content being viewed by others

References

Abbott IH, von Doenhoff AE (2012) Theory of wing sections: including a summary of airfoil data. Dover books on aeronautical engineering. Dover Publications, Mineloa

Bartels RE, Stanford BK (2018) Aeroelastic optimization with an economical transonic flutter constraint using Navier–Stokes aerodynamics. J Aircr 55(4):1522–1530. https://doi.org/10.2514/1.C034675

Blasques JPAA (2012) User’s Manual for BECAS: a cross section analysis tool for anisotropic and inhomogeneous beam sections of arbitrary geometry. Risø DTU - National Laboratory for Sustainable Energy

Burdette DA, Kenway GK, Martins JRRA (2016) Aerostructural design optimization of a continuous morphing trailing edge aircraft for improved mission performance. In: 17th AIAA/ISSMO multidisciplinary analysis and optimization conference. https://doi.org/10.2514/6.2016-3209

Calderon D, Cooper JE, Lowenberg MH, Neild S, Coetzee E (2018) On the effect of including geometric nonlinearity in the sizing of a wing. https://doi.org/10.2514/6.2018-1680

Calderon DE, Cooper JE, Lowenberg M, Neild SA, Coetzee EB (2019) Sizing high-aspect-ratio wings with a geometrically nonlinear beam model. J Aircr 56(4):1455–1470. https://doi.org/10.2514/1.C035296

Conlan-Smith C, Andreasen CS (2021) Aeroelastic optimization of aircraft wings using a coupled three-dimensional panel-beam model. AIAA J 59(4):1374–1386. https://doi.org/10.2514/1.J059911

Conlan-Smith C, Ramos-García N, Sigmund O, Andreasen CS (2020) Aerodynamic shape optimization of aircraft wings using panel methods. AIAA J 58(9):3765–3776. https://doi.org/10.2514/1.J058979

Conlan-Smith C, Ramos-García N, Andreasen CS (2021) Aerodynamic shape optimization of highly non-planar raised and drooped wings. J Aircr. https://doi.org/10.2514/1.C036403

Crisfield MA (1990) A consistent co-rotational formulation for non-linear, three-dimensional, beam-elements. Comput Methods Appl Mech Eng 81(2):131–50. https://doi.org/10.1016/0045-7825(90)90106-V

Crisfield MA (1997) Non-linear finite element analysis of solids and structures. Volume 2: advanced topics. Wiley, Hoboken

Drela M (1999) Integrated simulation model for preliminary aerodynamic, structural, and control-law design of aircraft. https://doi.org/10.2514/6.1999-1394

Drela M (2014) Flight vehicle aerodynamics. MIT Press, Cambridge

Dunning PD, Stanford BK, Kim HA (2015) Coupled aerostructural topology optimization using a level set method for 3d aircraft wings. Struct Multidisc Optim 51(5):1113–1132. https://doi.org/10.1007/s00158-014-1200-1

Gams M, Planinc I, Saje M (2007) The strain-based beam finite elements in multibody dynamics. J Sound Vib 305(1):194–210. https://doi.org/10.1016/j.jsv.2007.03.055

Gams M, Saje M, Srpcic S, Planinc I (2007) Finite element dynamic analysis of geometrically exact planar beams. Comput Struct 85(17):1409–1419. https://doi.org/10.1016/j.compstruc.2006.08.081

Garcia JA (2005) Numerical investigation of nonlinear aeroelastic effects on flexible high-aspect-ratio wings. J Aircr 42(4):1025–1036. https://doi.org/10.2514/1.6544

Gray AC, Martins JRRA (2021) Geometrically nonlinear high-fidelity aerostructural optimization for highly flexible wings. In: AIAA Scitech 2021 Forum. https://doi.org/10.2514/6.2021-0283

Gray JS, Hwang JT, Martins JRRA, Moore KT, Naylor BA (2019) Openmdao: an open-source framework for multidisciplinary design, analysis, and optimization. Struct Multidisc Optim 59(4):1075–1104. https://doi.org/10.1007/s00158-019-02211-z

Hodges DH (1990) A mixed variational formulation based on exact intrinsic equations for dynamics of moving beams. Int J Solids Struct 26(11):1253–1273. https://doi.org/10.1016/0020-7683(90)90060-9

Hodges DH (2003) Geometrically exact, intrinsic theory for dynamics of curved and twisted anisotropic beams. AIAA J 41(6):1131–1137. https://doi.org/10.2514/2.2054

Hodges DH (2006) Nonlinear composite beam theory, vol 213. American Institute of Aeronautics and Astronautics, Reston

Howcroft C, Calderon D, Lambert L, Castellani M, Cooper JE, Lowenberg MH, Neild S (2016) Aeroelastic modelling of highly flexible wings. https://doi.org/10.2514/6.2016-1798

James KA, Kennedy GJ, Martins JRRA (2014) Concurrent aerostructural topology optimization of a wing box. Comput Struct 134:1–17. https://doi.org/10.1016/j.compstruc.2013.12.007

Jansen PW, Perez RE, Martins JRRA (2010) Aerostructural optimization of nonplanar lifting surfaces. J Aircr 47(5):1490–1503. https://doi.org/10.2514/1.44727

Jasa JP, Hwang JT, Martins JRRA (2018) Open-source coupled aerostructural optimization using python. Struct Multidisc Optim 57(4):1815–1827. https://doi.org/10.1007/s00158-018-1912-8

Johnson DF, Gendler S (1950) Determination of minimum moments of inertia of arbitrarily shaped areas, such as hollow turbine blades. NACA RM E9H10. National Aeronautics and Space Administration

Katz J, Plotkin A (2001) Low-speed aerodynamics. Cambridge Aerospace Series Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9780511810329

Kennedy GJ, Martins JRRA (2012) A comparison of metallic and composite aircraft wings using aerostructural design optimization. In: 12th AIAA aviation technology, integration and operations (ATIO) Conference and 14th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference. American Institute of Aeronautics and Astronautics Inc., https://doi.org/10.2514/6.2012-5475

Kenway GKW, Martins JRRA (2014) Multipoint high-fidelity aerostructural optimization of a transport aircraft configuration. J Aircr 51(1):144–160. https://doi.org/10.2514/1.C032150

Kenway GKW, Kennedy GJ, Martins JRRA (2014) Scalable parallel approach for high-fidelity steady-state aeroelastic analysis and adjoint derivative computations. AIAA J 52(5):935–951. https://doi.org/10.2514/1.J052255

Khosravi S, Zingg DW (2018) Aerostructural optimization of drooped wings. J Aircr 55(3):1261–1268. https://doi.org/10.2514/1.C034605

Kosmatka JB (1992) The use of cross-section warping functions in composite rotor blade analysis. Report no. SSRP-92/11. National Aeronautics and Space Administration

Krenk S (2009) Non-linear modelling and analysis of solids and structures. Cambridge University Press, Cambridge

Kroo I (2005) Nonplanar wing concepts for increased aircraft efficiency. In: VKI lecture series on innovative configurations and advance concepts for future civil aircraft

Kuettler U, Wall WA (2008) Fixed-point fluid-structure interaction solvers with dynamic relaxation. Comput Mech 43(1):61–72. https://doi.org/10.1007/s00466-008-0255-5

Larsen TJ, Hansen AM (2007) How 2 HAWC2, the user’s manual. Risø National Laboratory, Roskilde

Lazos BS, Visser KD, Lazos BS, Lazos BS, Visser KD, Visser KD (2006) Aerodynamic comparison of hyper-elliptic cambered span (HECS) wings with conventional configurations. Collection of Technical Papers - AIAA Applied Aerodynamics Conference 3:1608–1625. https://doi.org/10.2514/6.2006-3469

Lupp CA, Cesnik CE (2019) A gradient-based flutter constraint including geometrically nonlinear deformations. https://doi.org/10.2514/6.2019-1212

Maute K, Allen M (2004) Conceptual design of aeroelastic structures by topology optimization. Struct Multidisc Optim 27(1–2):27–42. https://doi.org/10.1007/s00158-003-0362-z

Mieloszyk J, Goetzendorf-Grabowski T (2017) Introduction of full flight dynamic stability constraints in aircraft multidisciplinary optimization. Aerosp Sci Technol 68:252–260. https://doi.org/10.1016/j.ast.2017.05.024

Natella M, Wang X, Breuker RD (2018) The effects of aeroelastic tailoring on flight dynamic stability. https://doi.org/10.2514/6.2018-0191

Patil MJ, Hodges DH, Cesnik CES (2001) Nonlinear aeroelasticity and flight dynamics of high-altitude long-endurance aircraft. J Aircr 38(1):88–94. https://doi.org/10.2514/2.2738

Ranjan P, Ansell PJ, James KA (2019) Optimal hyperelliptic cambered span configurations for minimum drag. J Aircr 56(1):356–368. https://doi.org/10.2514/1.C034992

Simo JC, Vu-Quoc L (1986) A three-dimensional finite-strain rod model. II. Computational aspects. Comput Methods Appl Mech Eng 58(1):79–116. https://doi.org/10.1016/0045-7825(86)90079-4

Smith SC (1996) A computational and experimental study of nonlinear aspects of induced drag. Technical Paper 3598. National Aeronautics and Space Administration

Stanford BK, Dunning PD (2015) Optimal topology of aircraft rib and spar structures under aeroelastic loads. J Aircr 52(4):1298–1311. https://doi.org/10.2514/1.C032913

Su W, Cesnik CES (2010) Nonlinear aeroelasticity of a very flexible blended-wing-body aircraft. J Aircr 47(5):1539–1553. https://doi.org/10.2514/1.47317

Svanberg K (1987) The method of moving asymptotes—a new method for structural optimization. Int J Numer Meth Eng 24(2):359–373. https://doi.org/10.1002/nme.1620240207

Variyar A, Economon TD, Alonso JJ (2017) Design and optimization of unconventional aircraft configurations with aeroelastic constraints. https://doi.org/10.2514/6.2017-0463

Vassberg JC, DeHaan MA, Rivers SM, Wahls RA (2008) Development of a common research model for applied CFD validation studies. Collection of Technical Papers - AIAA Applied Aerodynamics Conference. https://doi.org/10.2514/6.2008-6919

Werter N, De Breuker R (2016) A novel dynamic aeroelastic framework for aeroelastic tailoring and structural optimisation. Compos Struct 158:369–386. https://doi.org/10.1016/j.compstruct.2016.09.044

Whitcomb RT (1979) A design approach and selected wind tunnel results at high subsonic speeds for wing-tip mounted winglets. NASA TN D-8260. National Aeronautics and Space Administration

Xfoil Drela M (1989) An analysis and design system for low Reynolds number airfoils. In: Mueller TJ (ed) Low Reynolds number aerodynamics. Springer, Berlin

Yu W, Volovoi VV, Hodges DH, Hong X (2002) Validation of the variational asymptotic beam sectional analysis. AIAA J 40(10):2105–2112. https://doi.org/10.2514/2.1545

Funding

This work was funded the Villum Foundation under the InnoTop Villum Investigator project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Additional information

Responsible Editor: Graeme James Kennedy

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendices

Local orientation in 3D space

The local orientation of the beam can be expressed in 3 forms: a rotation matrix which is used throughout the finite element analysis, Euler angles which describe the degrees of freedom in the finite element analysis, and quaternions which are represented as a scalar \({\bar{q}}\) and vector \({\varvec{q}}\). Quaternions are introduced because rotations in the first two forms are non-additive in 3D space (Crisfield 1997; Krenk 2009). The following procedure is adopted to calculate the current orientation, T, from an initial configuration, \(\mathbf{T} _0\), having undergone the Euler rotations \(\varvec{\theta }\). For more details on the theory of this procedure, readers are referred to Crisfield (1997), Chapter 16.

-

1.

Convert initial configuration, \(\mathbf{T} _0\), to a quaternion representation, \({\bar{q}}_0,{\varvec{q}}_0\). If \(\max (\text {Tr}(\mathbf{T _0}),T_{0,11},T_{0,22},T_{0,33}) = \text {Tr}(\mathbf{T _0})\) then

$$\begin{aligned} {\bar{q}}_0= & {} \frac{1}{2}\sqrt{1+\text {Tr}(\mathbf{T _0})} \end{aligned}$$(25a)$$\begin{aligned} q_{0,i}= & {} \frac{T_{0,kj}-T_{0,jk}}{4{\bar{q}}}\quad \text {for} \ i=1,2,3 \end{aligned}$$(25b)with i, j, k as the cyclic combination of 1,2,3. If \(\max (\text {Tr}(\mathbf{T _0}),T_{0,11},T_{0,22},T_{0,33}) \ne \text {Tr}(\mathbf{T _0})\) but instead \(=T_{0,ii}\)

$$\begin{aligned} q_{0,i}= & {} \sqrt{\frac{1}{2}T_{0,ii}+\frac{1}{4}(1-\text {Tr}(\mathbf{T _0}))} \end{aligned}$$(26a)$$\begin{aligned} {\bar{q}}_0= & {} \frac{T_{0,kj}-T_{0,jk}}{4q_i} \end{aligned}$$(26b)$$\begin{aligned} q_{0,l}= & {} \frac{T_{0,li}-T_{0,il}}{4q_i} \text {for} \ l=j,k \end{aligned}$$(26c)where the operation \(\text {Tr}(\mathbf{T} _0)\) represents the trace of \(\mathbf{T} _0\).

-

2.

Convert the Euler rotations \(\varvec{\theta }\) to a quaternion representation, \({\bar{q}}_r,{\varvec{q}}_r\).

$$\begin{aligned} {\bar{q}}_r= & {} c_1 c_2 c_3 + s_1 s_2 s_3 \end{aligned}$$(27a)$$\begin{aligned} q_{r,1}= & {} s_1 c_2 c_3 - c_1 s_2 s_3 \end{aligned}$$(27b)$$\begin{aligned} q_{r,2}= & {} c_1 s_2 c_3 + s_1 c_2 s_3 \end{aligned}$$(27c)$$\begin{aligned} q_{r,3}= & {} c_1 c_2 s_3 - s_1 s_2 c_3 \end{aligned}$$(27d)where \(c_i = \cos \big (\frac{\theta _i}{2}\big )\) and \(s_i = \sin \big (\frac{\theta _i}{2}\big )\).

-

3.

Calculate the quaternion representation of the current orientation as the quaternion sum of the initial orientation and the rotation

$$\begin{aligned} {\bar{q}}= & {} {\bar{q}}_0{\bar{q}}_r - {\varvec{q}}_0\cdot {\varvec{q}}_r \end{aligned}$$(28a)$$\begin{aligned} {\varvec{q}}= & {} {\bar{q}}_0{\varvec{q}}_r + {\bar{q}}_r{\varvec{q}}_0 - {\varvec{q}}_0\times {\varvec{q}}_r \end{aligned}$$(28b) -

4.

Convert back to the rotation matrix representation

$$\begin{aligned} \mathbf{T} = ({\bar{q}}^2 - {\varvec{q}}^\text {T}{\varvec{q}})\mathbf{I} + 2({\varvec{q}}{\varvec{q}}^\text {T}) + 2{\bar{q}}{} \mathbf{S} ({\varvec{q}}) \end{aligned}$$(29)where I is the identity matrix and \(\mathbf{S} ({\varvec{q}})\) is the skew-symmetric matrix form of the cross product operation defined as

$$\begin{aligned} \mathbf{S} ({\varvec{q}}) = \begin{pmatrix} 0 &{}\quad -q_3 &{}\quad q_2 \\ q_3 &{}\quad 0 &{}\quad -q_1 \\ -q_2 &{}\quad q_1 &{}\quad 0 \end{pmatrix} \end{aligned}$$(30)

Cross-sectional properties

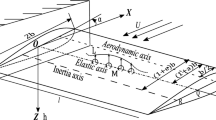

This work assumes a solid isotropic cross section whose geometry is defined by the airfoil parameterization represented in Fig. 2. The parameterization is based on the equations for NACA 4-digit airfoils (Abbott and von Doenhoff 2012) which define thickness and camber distributions as

NACA 4-digit airfoils define the thickness as normal to the camber line. The current parameterization modifies this definition such that thickness is measured normal to the chord line which ensures the derivatives are continuous (Conlan-Smith et al. 2020). The upper and lower surface of the airfoil are then be defined as

where the origin is at the leading edge, and subscripts u and l represent upper and lower surfaces, respectively. Now that there are analytic expressions for the airfoil, the following cross-sectional properties can be derived through evaluating the integrals provided in Johnson and Gendler (1950)

Properties notated with a tilde are defined with respect to the airfoil’s leading edge, but cross-sectional properties in (16) are defined with respect to the beam center and therefore properties in Eqs. (35)–(39) need to be corrected, e.g., using the parallel axis theorem.

Cross-sectional properties that cannot be calculated analytically include the location of the shear center and the torsional stiffness. The torsional stiffness is calculated using a technique in Kosmatka (1992) where J about the quarter chord point is approximated as \(J\simeq 0.15t^3c\). A similar approximation was formed for the location of the shear center in terms of the elastic center, by stating that

where \(k_x\) and \(k_z\) are coefficients that are constant for all airfoils defined by the parameterization above. BECAS (Blasques 2012) was used to evaluate \(k_x\) and \(k_z\) for a selection of airfoils with different values of m, t, and p. Based on average values, \(k_x\) and \(k_z\) were found to be 0.89 and 1.45, respectively.

Table 4 compares the difference in these approximations to the values calculated via BECAS. The approximation of the shear center was shown to be accurate to within 2% and 0.7% of the chord length for \({\tilde{x}}\) and \({\tilde{z}}\) locations, receptively. The torsional stiffness approximation had a maximum relative error of 6%. It is well known that dynamic analysis, such as determining flutter speeds, can be sensitive to torsional stiffness and location of the shear center. However, we have found that static analysis is not as sensitive to these quantities. This is demonstrated in Fig. 13, which plots the relative error in lift-to-drag ratios due to these approximations of torsional stiffness and shear center location. Each wing has a rectangular planform and constant airfoil sections which are chosen based on worst case scenarios from Table 4. For large aspect ratios and higher angles of attack, the deformations will increase and with it the error, but for each case studied the relative error remains below 1%.

Sensitivity analysis

Gradients are calculated using a discrete adjoint method, where the total derivative of an objective/constraint function \(\Psi\) can be calculated as

where partial derivatives capture only the explicit dependence without solving the governing equations. The terms \(\varvec{\lambda }_a\) and \(\varvec{\lambda }_b\) are Langragian multipliers whose length is equal to that of \(\varvec{\mu }\) and \(\mathbf{u}\) , respectively, and are calculated through solving the following adjoint problem

Partial derivatives are calculated using analytic expressions, refer to Conlan-Smith et al. (2020) for further details. The viscous drag is calculated through linearly interpolating pre-calculated data points with respect to the airfoil geometry parameters. Hence, the slope of this interpolation can be used in calculating gradients. Since the interpolation is linear the gradient of the viscous drag is also first-order accurate.

Convergence behavior

An example of the typical convergence behavior for lift-to-drag ratios is shown in Fig. 14. It is difficult to choose an initial design where the lift-weight equilibrium constraint is satisfied, and as such, the initial designs are in the infeasible region of the design space. This can cause the performance to be reduced in the first few iterations as the optimizer tries to satisfy this constraint. Once in the feasible region, there is a smooth convergence behavior. Generally when viscous effects are included, there is a slight increase in the number of iterations required to meet the stopping criteria.

Convergence history for designs shown in Fig. 7a and b. The y-axis plots the improvement in lift-to-drag ratio compared to the initial design

Rights and permissions

About this article

Cite this article

Conlan-Smith, C., Andreasen, C.S. Aeroelastic shape optimization of solid foam core wings subject to large deformations. Struct Multidisc Optim 65, 161 (2022). https://doi.org/10.1007/s00158-022-03246-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-022-03246-5