Abstract

We present a novel multiphysics and multimaterial computational design framework for shape-memory alloy-based smart structures. The proposed framework uses topology optimization to optimally distribute multiple material candidates within the design domain, and leverages a nonlinear phenomenological constitutive model for shape-memory alloys (SMAs), along with a coupled transient heat conduction model. In most practical scenarios, SMAs are activated by a nonuniform temperature field or a nonuniform stress field. This framework accurately captures the coupling between the phase transformation process and the evolution of the local temperature field. Thus, the resulting design framework is able to optimally tailor the two-way shape-memory effect and the superelasticity response of SMAs more precisely than previous algorithms that have relied on the assumption of a uniform temperature distribution. We present several case studies, including the design of a self-actuated bending beam and a gripper mechanism. The results show that the proposed framework can successfully produce SMA-based designs that exhibit targeted displacement trajectories and output forces. In addition, we present an example in which we enforce material-specific thermal constraints in a multimaterial design to enhance its thermal performance. In conclusion, the proposed framework provides a systematic computational approach to consider the nonlinear thermomechanical response of SMAs, thereby providing enhanced programmability of the SMA-based structure.

Similar content being viewed by others

Notes

Note that it is generally assumed that the thermal expansion parameter \(\alpha\) and specific heat c of SMAs in the martensite and austenite phases are the same (Lagoudas 2008), as their relative differences could be smaller than \(5\%\). Further, the pure thermal expansion effect contributes only a small portion of the total strain, compared with the inelastic deformation. However, this work is adaptable to assumptions of different thermal expansion parameters and specific heat in the martensite and austenite phases.

For simplicity, we assume that all the material candidates have the same thermal expansion coefficient(\(\alpha\)), specific heat (c) and Poisson ratio v.

Note that one may also treat the multimaterial composite within each element as a whole unit having transformation behavior, i.e., \(f_\mathrm{int}=\bigwedge _\mathrm{el}\sum _{\mathfrak { G}}\sum _{j=1}^{m}\mu _\mathrm{el}^{(j)}E^{(j)}[{\varvec{\varepsilon }}^{\mathfrak {G}}-{\varvec{\alpha }(T-T_0)} - \varepsilon ^{t}]\). However, extremely strong assumptions on physical properties of the composite are needed so that the transformation temperature of the composite unit is identical to that of the SMA, or the transformation temperature of the composite follows a proposed interpolation rule. One also needs to make the assumption that the transformation behaviors of the physical properties of the composites still follow Eq. 7. To avoid such strong assumptions, we suggest decomposing the stress tensor and evaluating the transformation behavior only for the portion of each element that contains SMAs.

References

Bendsøe MP, Sigmund O (1999) Material interpolation schemes in topology optimization. Arch Appl Mech 69(9–10):635–654

Bhattacharya K, Kohn RV (1996) Symmetry, texture and the recoverable strain of shape-memory polycrystals. Acta Mater 44(2):529–542

Bhattacharyya A, James KA (2021) Topology optimization of shape memory polymer structures with programmable morphology. Struct Multidisc Optim 63(4):1863–1887

Bhattacharya K et al (2003) Microstructure of martensite: why it forms and how it gives rise to the shape-memory effect, vol 2. Oxford University Press, Oxford

Boyd JG, Lagoudas DC (1996) A thermodynamical constitutive model for shape memory materials. Part I. The monolithic shape memory alloy. Int J Plast 12(6):805–842

Boyd JG, Lagoudas DC (1996) A thermodynamical constitutive model for shape memory materials. Part II. The SMA composite material. Int J Plast 12(7):843–873

Buchanan C, Gardner L (2019) Metal 3D printing in construction: a review of methods, research, applications, opportunities and challenges. Eng Struct 180:332–348

Buenconsejo PJS, Kim HY, Hosoda H, Miyazaki S (2009) Shape memory behavior of Ti-Ta and its potential as a high-temperature shape memory alloy. Acta Mater. 57(4):1068–1077

Callister WD, Rethwisch DG (2018) Materials science and engineering: an introduction, vol 9. Wiley, New York

Chluba C, Ge W, de Miranda RL, Strobel J, Kienle L, Quandt E, Wuttig M (2015) Ultralow-fatigue shape memory alloy films. Science 348(6238):1004–1007

Cho S, Choi J-Y (2005) Efficient topology optimization of thermo-elasticity problems using coupled field adjoint sensitivity analysis method. Finite Elements Anal Des 41(15):1481–1495

Cisse C, Zaki W, Zineb TB (2016) A review of constitutive models and modeling techniques for shape memory alloys. Int J Plast 76:244–284

Elahinia MH (2016) Shape memory alloy actuators: design, fabrication, and experimental evaluation. Wiley, New York

Featherstone R, Teh YH (2006) Improving the speed of shape memory alloy actuators by faster electrical heating. Experimental robotics IX. Springer, Berlin, pp 67–76

Frost M, Benešová B, Sedlák P (2016) A microscopically motivated constitutive model for shape memory alloys: formulation, analysis and computations. Math Mech Solids 21(3):358–382

Fuchi K, Ware TH, Buskohl PR, Reich GW, Vaia RA, White TJ, Joo JJ (2015) Topology optimization for the design of folding liquid crystal elastomer actuators. Soft Matter 11(37):7288–7295

Gorbet R, Morris K, Chau R (2009) Mechanism of bandwidth improvement in passively cooled SMA position actuators. Smart Mater Struct 18(9):095013

James KA (2018) Multiphase topology design with optimal material selection using an inverse p-norm function. Int J Numer Methods Eng 114(9):999–1017

Jani JM, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des 1980–2015(56):1078–1113

Jebellat E, Baniassadi M, Moshki A, Wang K, Baghani M (2020) Numerical investigation of smart auxetic three-dimensional meta-structures based on shape memory polymers via topology optimization. J Intell Mater Syst Struct 31(15):1838–1852

Kang Z, James KA (2019) Multimaterial topology design for optimal elastic and thermal response with material-specific temperature constraints. Int J Numer Methods Eng 117(10):1019–1037

Kang Z, James KA (2020) Thermomechanical topology optimization of shape-memory alloy structures using a transient bilevel adjoint method. Int J Numer Methods Eng 121(11):2558–2580

Kang Z, Tortorelli DA, James KA (2022) Parallel projection-an improved return mapping method for finite element modeling of shape memory alloys. Comput Methods Appl Mech Eng 389C:114364

Karaca H, Saghaian S, Ded G, Tobe H, Basaran B, Maier H, Noebe R, Chumlyakov Y (2013) Effects of nanoprecipitation on the shape memory and material properties of an Ni-rich nitihf high temperature shape memory alloy. Acta Mater. 61(19):7422–7431

Kim S, Laschi C, Trimmer B (2013) Soft robotics: a bioinspired evolution in robotics. Trends Biotechnol 31(5):287–294

Kittel C, Kroemer H (1998) Thermal physics

Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications. Springer, Berlin

Lagoudas D, Hartl D, Chemisky Y, Machado L, Popov P (2012) Constitutive model for the numerical analysis of phase transformation in polycrystalline shape memory alloys. Int J Plast 32:155–183

Langelaar M, Yoon GH, Kim Y, Van Keulen F (2011) Topology optimization of planar shape memory alloy thermal actuators using element connectivity parameterization. Int J Numer Methods Eng 88(9):817–840

Lauhoff C, Sommer N, Vollmer M, Mienert G, Krooß P, Böhm S, Niendorf T (2020) Excellent superelasticity in a Co-Ni-Ga high-temperature shape memory alloy processed by directed energy deposition. Mater Res Lett 8(8):314–320

Lee H-T, Kim M-S, Lee G-Y, Kim C-S, Ahn S-H (2018) Shape memory alloy (sma)-based microscale actuators with 60% deformation rate and 1.6 kHz actuation speed. Small 14(23):1801023

Li Y, Saitou K, Kikuchi N (2004) Topology optimization of thermally actuated compliant mechanisms considering time-transient effect. Finite Elements Anal Des 40(11):1317–1331

Liang C, Rogers C (1992) A multi-dimensional constitutive model for shape memory alloys. J Eng Math 26(3):429–443

Liang C, Rogers CA (1997) One-dimensional thermomechanical constitutive relations for shape memory materials. J Intell Mater Syst Struct 8(4):285–302

Meng X-L, Zheng Y-F, Wang Z, Zhao L (2000) Shape memory properties of the Ti36Ni49Hf15 high temperature shape memory alloy. Mater. Lett. 45(2):128–132

Motzki P, Gorges T, Kappel M, Schmidt M, Rizzello G, Seelecke S (2018) High-speed and high-efficiency shape memory alloy actuation. Smart Mater Struct 27(7):075047

Ngo TD, Kashani A, Imbalzano G, Nguyen KT, Hui D (2018) Additive manufacturing (3d printing): a review of materials, methods, applications and challenges. Composites B 143:172–196

Qidwai M, Lagoudas D (2000) Numerical implementation of a shape memory alloy thermomechanical constitutive model using return mapping algorithms. Int J Numer Methods Eng 47(6):1123–1168

Qidwai M, Lagoudas D (2000) On thermomechanics and transformation surfaces of polycrystalline Niti shape memory alloy material. Int J Plast 16(10–11):1309–1343

Rodrigue H, Wang W, Han M-W, Kim TJ, Ahn S-H (2017) An overview of shape memory alloy-coupled actuators and robots. Soft Robot 4(1):3–15

Sigmund O (2001) Design of multiphysics actuators using topology optimization-part I: one-material structures. Comput Methods Appl Mech Eng 190(49–50):6577–6604

Sigmund O (2001) Design of multiphysics actuators using topology optimization-part II: two-material structures. Comput Methods Appl Mech Eng 190(49–50):6605–6627

Simo JC, Hughes TJ (2006). Computational inelasticity, vol 7. Springer, Berlin

Song S-H, Lee J-Y, Rodrigue H, Choi I-S, Kang YJ, Ahn S-H (2016) 35 Hz shape memory alloy actuator with bending-twisting mode. Sci Rep 6:21118

Sun QP, Hwang KC (1993) Micromechanics modelling for the constitutive behavior of polycrystalline shape memory alloys-I. Derivation of general relations. J Mech Phys Solids 41(1):1–17

Sun QP, Hwang KC (1993) Micromechanics modelling for the constitutive behavior of polycrystalline shape memory alloys-II. Study of the individual phenomena. J Mech Phys Solids 41(1):19–33

Svanberg K (1987) The method of moving asymptotes-a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373

Tanaka K, Nishimura F, Hayashi T, Tobushi H, Lexcellent C (1995) Phenomenological analysis on subloops and cyclic behavior in shape memory alloys under mechanical and/or thermal loads. Mech Mater 19(4):281–292

Tian R, Hang C, Tian Y, Feng J (2019) Brittle fracture induced by phase transformation of Ni-Cu-Sn intermetallic compounds in Sn-3Ag-0.5 Cu/Ni solder joints under extreme temperature environment. J Alloys Compd 777:463–471

Wellman PS, Peine WJ, Favalora G, Howe RD (1998) Mechanical design and control of a high-bandwidth shape memory alloy tactile display. Experimental robotics V. Springer, Berlin, pp 56–66

Ye J, Gao Y (2012) Metallurgical characterization of m-wire nickel-titanium shape memory alloy used for endodontic rotary instruments during low-cycle fatigue. J Endodont 38(1):105–107

Zhang F (2006) The Schur complement and its applications, vol 4. Springer, Berlin

Acknowledgements

This research was supported by the National Science Foundation through grant number CMMI1663566.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Replication of results

Detailed descriptions of the algorithms used to generate all results are provided throughout the paper. Additionally, we have included all relevant material properties, and all algorithm parameters. Copies of the code used to generate the results will be made available upon request.

Additional information

Responsible Editor: Seonho Cho

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Analytical derivation of adjoint vectors

In this appendix, we present the derivation of an analytical formulation for computing the tangent matrices described in Eq. 35. The motivation behind deriving these formulas is to avoid directly factorizing the ill-conditioned matrix \({\partial {\varvec{H}}_n}/{\partial \varvec{\nu }_n}\). For conciseness, we focus on the case where the behaviors of the SMA in the current time step and next step are inelastic. To start, we first represent the inverse of \({\partial {\varvec{H}}_{\mathfrak {G},n}}/{\partial \varvec{\nu }_{\mathfrak {G},n}}\) using the Schur complement (Zhang 2006).

with

Note that the analytical solution in which we directly factorize \({\partial {\varvec{H}}_n}/{\partial \varvec{\nu }_n}\) is not recommended for calculating the sensitivities. This analytical solution will not change the ill-conditioned characteristics of the matrix, since \((\mathbb {A+BC})\) is nearly singular due to the fact that the large value \(S^{-1}\) still appears on the lower triangle. Similarly, \({\partial {\varvec{H}}_{n+1}}/{\partial \varvec{\nu }_n}\) can be defined in block matrix form as

The five aforementioned matrices then can be represented in a new form shown below.

It can be observed that the key to obtaining an accurate solution of the tangent matrices lies in solving the inverse of \(\mathbb {(A+BC)}\). Here we use the Schur formulation again to calculate the inverse of the matrix.

with

Here, \(\mathbb {D'}^{-1}\) and \(\mathbb {(A'-B'}\mathbb {D'}^{-1}\mathbb {C')}^{-1}\) need to be solved. Note that it can be easily proven that \(\partial _{\varvec{\sigma }} \varvec{\Lambda }\) belongs to the null space of \(\varvec{\sigma }\), i.e., \(\partial _{\varvec{\sigma }} \varvec{\Lambda }\):\(\varvec{\sigma }\) = 0, hence \(\partial _{\varvec{\sigma }} \varvec{\Lambda }\) is not invertible. However, \(({{\varvec{S}}}_{n}+\partial _{\varvec{\sigma }} \varvec{\Lambda }_{n}:\Delta {\xi }_n)\) is nonsingular. Defining \(\varvec{\zeta } = {{\varvec{S}}}_{n}+\partial _{\varvec{\sigma }} \varvec{\Lambda }_{n}:\Delta {\xi }_n\), \(\mathbb {D'}^{-1}\) can be solved using the Schur form as

With the above information, one can obtain that

Then \(\mathbb {(A'-B'}\mathbb {D'}^{-1}\mathbb {C')}^{-1}\) is a scalar and can be calculated as \(Q=-\partial _{\varvec{\sigma }} \Phi _{n}:{\varvec{\zeta }}_{n}^{-1}:\partial _{\varvec{\sigma }} \Phi _{n}+\partial _{\xi } \Phi _{n}\). Hence the issue of the ill-conditioned matrix has been solved, and we are able to accurately evaluate the five matrices as follows.

where

When \(\partial _{\varvec{\sigma }}\varvec{\Lambda }=0\) and \(\varvec{\zeta } = {\varvec{S}}\), the above analytical solutions degenerate as follows

where

Note that the first equation in A.9 and A.11 can be recognized as the formulas for calculating the tangent stiffness matrix, shown in our work (Kang et al. 2022). Therefore, in addition to improving the accuracy of the sensitivity evaluation, we are able to conserve computational resources by re-using the tangent stiffness matrix already computed during the finite element analysis.

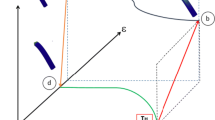

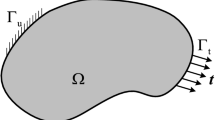

Appendix B: Comparison between analytical and finite difference sensitivity results

This section validates the adjoint sensitivity formulation by comparing the analytical results with finite differences. Figures 23 and 24 show the geometry and boundary conditions of the test case used to calculate the sensitivities in Fig. 6. Note that in the following tables from Tables 4, 5, 6, 7, 8 and 9, t refers to the time step; T and \(\xi\) refer to the temperature and martensite volume fraction evaluated at the node and Gauss point that are closest to point A, which is associated with the function of interest \(f_{int}\). ANA and FD refer to the analytical and finite difference sensitivity values, respectively.

1.1 Appendix B.1: Simulating two-way shape-memory effects

In the first case study we evaluate the sensitivity of the TWSME of a bi-material beam containing SMA and BC, whose properties are shown in Tables 2 and 3. The material volume fraction r (cf. Eq. 23) is uniformly 0.9 across the structure. The boundary conditions are shown below,

where a constant uniform surface traction \({\varvec{f}}= 9\times 10^7\mathrm{N/m}\) is applied when cooling the beam. The initial and reference temperature of the beam is set to be 250K. In addition, temperature \({\bar{T}}\) (cf. Fig. 23b) is fixed at 250 K during the cooling process. A heat flux increment \(\mathrm{d}q\) = \(1 \times 10^2\) w/m per time step, and a heat sink increment \(\mathrm{d}Q\) = \(-5 \times 10^3\) w/m\(^2\) per time step are applied to cool the beam. The function of interest \(f_{int}\) for sensitivity analysis (cf. Eq. 31) is the vertical displacement at point A of the structure, i.e., \(f_{int} = d_{y}^{A}\). We calculate the sensitivity of the displacement function under different mesh sizes and at different transformation stages. The numerical results are shown in Tables 4, 5, 6 and 6.

1.2 Appendix B.2: Simulating both two-way shape-memory effects and superelasticity

The second case study looks at sensitivity analysis of a single-material SMA structure undergoing both TWSME and superelasticity. The material volume fraction r (cf. Eq. 23) is uniformly 0.5 across the structure. The boundary conditions are shown in Fig. 24. An input force increment \(\mathrm{d}{\varvec{F}}_{in} = 1\times 10^6\)N per time step is applied to the structure to trigger superelasticity. Meanwhile, the structure is cooled with a heat flux increment \(\mathrm{d}q\) = \(1 \times 10^2\) w/m per time step, and a heat sink increment \(\mathrm{d}Q\) = \(-5 \times 10^3\) w/m\(^2\) per time step. The initial and reference temperature, as well as the fixed temperature \({\bar{T}}\) for the thermal conduction problem (cf. Fig. 24b) are set to be 230 K. The function of interest \(f_{int}\) for sensitivity analysis (cf. Eq. 31) is the mechanical advantage at point A, i.e., \(f_{int} = -{\varvec{F}}_{out}/{\varvec{F}}_{in}\). We calculate the sensitivity of the structure, under different mesh sizes and at different transformation stages. The numerical results are shown in Tables 7 to 9

Rights and permissions

About this article

Cite this article

Kang, Z., James, K.A. Multiphysics design of programmable shape-memory alloy-based smart structures via topology optimization. Struct Multidisc Optim 65, 24 (2022). https://doi.org/10.1007/s00158-021-03101-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-021-03101-z