Abstract

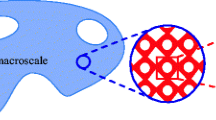

With the goal of identifying optimal elastic single-scale microstructures for multiple loading situations, the paper shows that qualified starting guesses, based on knowledge of optimal rank-3 laminates, significantly improves chances of convergence to near optimal designs. Rank-3 laminates, optimal for a given set of anisotropic loading conditions, are approximated on a single scale using a simple mapping approach. We demonstrate that these mapped microstructures perform relatively close to theoretical energy bounds. Microstructures with a performance even closer to the bounds can be obtained by using the approximated rank-3 structures in a further step as starting guesses for inverse homogenization problems. Due to the nonconvex nature of inverse homogenization problems, the starting guesses based on rank-3 laminates outperform classical starting guesses with homogeneous or random material distributions. Furthermore, the obtained single-scale microstructures are relatively simple, which enhances manufacturability. Results, obtained for a wide range of loading cases, indicate that microstructures with performance within 5–8% of the theoretical optima can be guarantied, as long as feature sizes are not limited by minimium size constraints.

Similar content being viewed by others

References

Allaire G (2002) Shape optimization by the homogenization method. Springer, New York

Allaire G, Aubry S (1999) On optimal microstructures for a plane shape optimization problem. Structural Optimization 17(2):86–94

Allaire G, Geoffroy-Donders P, Pantz O (2018) Topology optimization of modulated and oriented periodic microstructures by the homogenization method, working paper or preprint. Computer & Mathematics with Applications

Andreassen E, Andreasen C (2014) How to determine composite material properties using numerical homogenization. Commun Math Sci 83:488–495

Andreassen E, Lazarov BS, Sigmund O (2014) Design of manufacturable 3D extremal elastic microstructure. Mech Mater 69(1):1–10

Avellaneda M (1987) Optimal bounds and microgeometries for elastic two-phase composites. SIAM J Appl Math 47(6):1216–1228

Avellaneda M, Milton G (1988) Bounds on the effective elasticity tensor of composites based on two-point correlations. In: American society of mechanical engineers, Petroleum division (Publication) PD. vol 24. American Society of Mechanical Engineers (ASME), pp 89–93

Bendsøe M, Sigmund O (2004) Topology optimization-theory, methods and applications. Springer, Berlin

Berger J, Wadley H, McMeeking R (2017) Mechanical metamaterials at the theoretical limit of isotropic elastic stiffness. Nature 543(7646):533–537

Bourdin B, Kohn RV (2008) Optimization of structural topology in the high-porosity regime. J Mech Phys Solids 56(3):1043–1064

Cherkaev A (2000) Variational methods for structural optimization. Springer, New York

Clausen A, Wang F, Jensen JS, Sigmund O, Lewis JA (2015) Topology optimized architectures with programmable Poisson’s ratio over large deformations. Adv Mater 27(37):5523–5527

Coelho P, Cardoso J, Fernandes P, Rodrigues H (2011) Parallel computing techniques applied to the simultaneous design of structure and material. Adv Eng Softw 42(5):219–227

Díaz AR, Lipton R, Soto CA (1995) A new formulation of the problem of optimum reinforcement of Reissner-Mindlin plates. Comput Methods Appl Mech Eng 123(1):121–139

Francfort GA, Murat F (1986) Homogenization and optimal bounds in linear elasticity. Arch Ration Mech Anal 94(4):307–334

Grabovsky Y, Kohn RV (1995) Anisotropy of the Vigdergauz microstructure. J Appl Mech 62(4):1063–1065

Groen JP, Sigmund O (2017) Homogenization-based topology optimization for high-resolution manufacturable micro-structures. Int J Numer Methods Eng 113(8):1148–1163

Guedes J, Rodrigues H, Bendsøe MP (2003) A material optimization model to approximate energy bounds for cellular materials under multiload conditions. Struct Multidiscip Optim 25(5-6):446–452

Guest J, Prévost J, Belytschko T (2004) Achieving minimum length scale in topology optimization using nodal design variables and projection functions. Int J Numer Methods Eng 61(2):238– 254

Krein M, Nudelman A (1977) The Markov moment problem and extremal problems, Translations of mathematical monographs, vol 50. American Mathematical Society, Providence, Rhode Island

Larsen UD, Sigmund O, Bouwsta S (1997) Design and fabrication of compliant micromechanisms and structures with negative Poisson’s ratio. J Microelectromech Syst 6(2):99–106

Lipton R (1994) On optimal reinforcement of plates and choice of design parameters. Control Cybern 23 (3):481–493

Liu L, James R, Leo P (2007) Periodic inclusion–matrix microstructures with constant field inclusions. Metall and Mater Trans A 38(4):781–787

Liu L, Yan J, Cheng G (2008) Optimum structure with homogeneous optimum truss-like material. Computers & Structures 86(13):1417–1425. structural Optimization

Lurie KA, Cherkaev AV (1984) G-closure of a set of anisotropically conducting media in the two-dimensional case. J Optim Theory Appl 42(2):283–304

Milton GW (1986) Modelling the properties of composites by laminates. In: Ericksen JL, Kinderlehrer D, Kohn R, Lions J (eds) Homogenization and effective moduli of materials and media. Springer, New York, pp 150–174

Neves MM, Sigmund O, Bendsøe MP (2002) Topology optimization of periodic microstructures with a penalization of highly localized buckling modes. Int J Numer Methods Eng 54(6):809–834

Osanov M, Guest JK (2016) Topology optimization for architected materials design. Annu Rev Mater Res 46(1):211–233

Pantz O, Trabelsi K (2008) A post-treatment of the homogenization method for shape optimization. SIAM J Control Optim 47(3):1380–1398

Rodrigues H, Guedes J (2002) Hierarchical optimization of material and structure. Struct Multidiscip Optim 24(1):1–10

Schury F, Stingl M, Wein F (2012) Efficient two-scale optimization of manufacturable graded structures. SIAM J Sci Comput 34(6):B711–B733

Sigmund O (1994) Materials with prescribed constitutive parameters: an inverse homogenization problem. Int J Solids Struct 31(17):2313–2329

Sigmund O, Bendsøe MP (1999) On the optimality of bone microstructure. In: Pedersen P (ed) IUTAM symposium on synthesis in bio solid mechanics. Springer, Netherlands, pp 221–234

Sigmund O (2000) A new class of extremal composites. J Mech Phys Solids 48(2):397–428

Sigmund O, Aage N, Andreassen E (2016) On the (non-)optimality of Michell structures. Struct Multidiscip Optim 54:361–372

Sivapuram R, Dunning PD, Kim HA (2016) Simultaneous material and structural optimization by multiscale topology optimization. Struct Multidiscip Optim 54(5):1267–1281

Svanberg K (1987) The method of moving asymptotes—a new method for structural optimization. Int J Numer Methods Eng 24(2):359–373

Thomsen CR, Wang F, Sigmund O (2018) Buckling strength topology optimization of 2D periodic materials based on linearized bifurcation analysis. Comput Methods Appl Mech Eng 339:115–136

Vigdergauz SB (1994a) Three-dimensional grained composites of extreme thermal properties. J Mech Phys Solids 42(5):729–740

Vigdergauz SB (1994b) Two-dimensional grained composites of extreme rigidity. J Appl Mech 61(2):390–394

Xia L, Breitkopf P (2017) Recent advances on topology optimization of multiscale nonlinear structures. Arch Comput Meth Eng 24(2):227–249

Acknowledgements

The authors acknowledge the support of the Villum Fonden through the Villum investigator project InnoTop. The authors would also like to thank Krister Svanberg for providing the MATLAB MMA code.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Gregoire Allaire

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Reconstructing a rank-3 laminate from moments

Appendix: Reconstructing a rank-3 laminate from moments

In this section, we discuss the method proposed by Lipton (1994) to reconstruct the relative layer contributions pn and orientations 𝜃n of a rank-3 laminate from the optimal moments. Our discussion is similar to the practical implementation given by Díaz et al. (1995), and included for completeness.

We can reduce the set of optimal moments from four to three, by rotating the set of moments (m1, m2, m3, m4) to \((\tilde {m}_{1},\tilde {m}_{2},\tilde {m}_{3},0)\) using a change of reference frame and rotation angle γ such that \(\tilde {\theta }_{n} = \theta _{n}+\gamma \) and the following:

By using the rotated reference frame for the specification of the layer tangents tn, used in (5), the following relations can be found as follows:

Hence, we can find γ that ensures \(\tilde {m}_{4}= 0\) using the following:

From (17), it can be seen that γ is periodic every π/4. This means that there are at least four rotated sets \(\tilde {\boldsymbol {m}}\) to describe the microstructure. Furthermore, the feasible rotated set of moments \(\tilde {\mathcal {M}}\) is bounded by the same constraints as in (18).

Feasible set \(\tilde {\mathcal {M}}\) is a convex set as can be seen in Fig. 16.

The boundary of this convex set \(\partial \tilde {\mathcal {M}}\) satisfies the following:

while the four corner points also satisfy the following:

It can easily be verified using (15) that the four corner points \(\tilde {\boldsymbol {m}} = \left \{1,0,1\right \}\), {− 1, 0, 1}, {0, 1,− 1} and {0,− 1,− 1} correspond to rank-1 laminates, with the corresponding layer directions \(\tilde {\theta }_{1}= 0\), π/2, π/4, and − π/4 respectively. Hence, if both (19) and (20) are satisfied, the microstructure is a rank-1 microstructure. Depending on the choice of γ, the unique layer orientation 𝜃1 can be obtained; furthermore, corresponding p1 = 1.

Since \(\tilde {\mathcal {M}}\) is a convex set, each point \(\tilde {\boldsymbol {m}}\) can be described as a combination of a corner point \(\tilde {\boldsymbol {a}}\) and a point \(\tilde {\boldsymbol {b}}\) on \(\partial \tilde {\mathcal {M}}\) as follows:

Since \(\tilde {\boldsymbol {a}}\) corresponds to a rank-1 laminate, point \(\tilde {\boldsymbol {b}}\) on boundary \(\partial \tilde {\mathcal {M}}\) has to correspond to a rank-2 laminate. Hence,

Furthermore, we have the following:

If we take one of the corner points, e.g., \(\tilde {\boldsymbol {a}} = \left \{1,0,1\right \}\), we can solve for \(\tilde {\boldsymbol {b}}\) and α, using the Equations above. We know that the rank-2 laminate can be described using two relative layer contributions \(p_{1}^{\tilde {b}}\) and \(p_{2}^{\tilde {b}}\), and two angles \(\theta _{1}^{\tilde {b}}\) and \(\theta _{2}^{\tilde {b}}\), such as the following:

This is system of four equations can be solved for the four unknowns. To do so, one can describe \(\tilde {\boldsymbol {b}}\) in terms of two angles, 0 ≤ t ≤ 2π and 0 ≤ β ≤ π/2 (Lipton 1994).

The corresponding solution for the rank-2 laminate can then be written as follows:

The corresponding rank-3 laminate in global frame of reference can thus be written as follows:

Rights and permissions

About this article

Cite this article

Träff, E., Sigmund, O. & Groen, J.P. Simple single-scale microstructures based on optimal rank-3 laminates. Struct Multidisc Optim 59, 1021–1031 (2019). https://doi.org/10.1007/s00158-018-2180-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-018-2180-3