Abstract

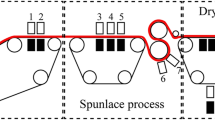

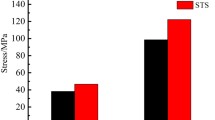

Wood pulp-based wetlaid/spunlace (wetlace) materials have become increasingly popular in the field of disposable personal hygiene moist wipes. To achieve excellent products, materials with different short-cut fibers and proportions were fabricated, and the effects of moisture contents on the wet strength and handle properties of the materials were firstly investigated. The results suggest that the wet strength of material composed of regenerated cellulose fibers decreases to about 20% of dry strength, while that made of hydrophilic polyester is only about 8–9% with moisture content of 800%. The softness and smoothness of material consisting of 20% short-cut regenerated cellulose fibers decrease to stable figures at 300% moisture content. The softness parameter was 4.5–5.2, and the smoothness value was 14.5–19, but the stiffness parameter increases to a stable level at 2.6–2.9 mm N−1. Overall, with moisture content of 300%, materials with 20% short-cut fibers achieve the limit of wet strength during use, material made of lyocell has the best wet strength and smoothness, and material made of Viloft possesses the greatest softness and the lowest stiffness.

Similar content being viewed by others

References

Abu-Rous M, Liftinger E, Innerlohinger J, Malengier B, Vasile S (2017a) A new physical method to assess handle properties of fabrics made from wood-based fibers. In: Proceedings of IOP conference series: materials science and engineering, vol 93. Lenzinger Berichte pp 65–71

Abu-Rous M, Malengier B, Liftinger E, Innerlohinger J (2017b) Handfeel of single jersey fabrics as assessed by new physical method. J Fash Technol Text Eng S 4:006

Atasağun HG, Bhat GS (2020) Advancement in flushable wipes: modern technologies and characterization. J Ind Text 49:722–747

Baker JP, Curran M, Hurley JS, Moose RT, Dutkiewicz JK, Murcia MV, Hess T (2016) Dispersible nonwoven wipe material. Patent 9661974 B2, US

Bernt I, Eckhart R (2013) Design of viscose fibres for wetlaid nonwovens. Lenzinger Berichte 91:71–76

Deng C, Liu W, Zhang Y, Huang C, Zhao Y, Jin X (2018) Environmentally friendly and breathable wet-laid hydroentangled nonwovens for personal hygiene care with excellent water absorbency and flushability. Roy Soc open sci 5:171486

Deng C, Gong RH, Huang C, Zhang X, Jin X-Y (2019) Tensile strength and dispersibility of pulp/danufil wet-laid hydroentangled nonwovens. Materials 12:3931

El Mogahzy Y, Kilinc F, Hassan M (2005) Developments in measurement and evaluation of fabric hand. Effect of mechanical and physical properties on fabric hand. Camridge England, Woodhead publishing Limited, UK, pp 45–65

Emtec (2014) TSA: tissue softness analyzer, leaflet collection

Grüner G (2011) TSA-tissue softness analyzer. A new and objective measuring technique to analyzer the softness of tissue. Przeglad Papierniczy 67:161–164

Hwang JH, Lee C-H, Lee HH, Kim SY (2014) A new soft tissue volume measurement strategy using ultrasonography. Lymphat res biol 12:89–94

Kayseri GÖ, Özdil N, Mengüç GS (2012) Sensorial comfort of textile materials. Woven Fabrics pp 235–266

Lagardère M, Park CH, Panier S (2014) Permeability of natural fiber reinforcement for liquid composite molding processes. J mater sci 49:6449–6458

Liu D, Song J, Anderson DP, Chang PR, Hua Y (2012) Bamboo fiber and its reinforced composites: structure and properties. Cellulose 19:1449–1480

Malpot A, Touchard F, Bergamo S (2015) Effect of relative humidity on mechnical properties of a woven thermoplastic composite for automotive application. Polym Test 48:160–168

Mango P (2004) Flushable wipes–past, present and future. Nonwovens Industry, pp 64–71

Mao N, Russell SJ (2006) A framework for determining the bonding intensity in hydroentangled nonwoven fabrics. Compos Sci Technol 66:80–91

Mitchell R-L, Thamsen PU, Gunkel M, Waschnewski J (2017) Investigations into wastewater composition focusing on nonwoven wet wipes. Czasopismo Techniczne 2017:125–135

Moura D, Souza M, Liverani L, Rella G, Luz G, Mano J, Boccaccini A (2017) Development of a bioactive glass-polymer composite for wound healing applications. Mat Sci Eng C 76:224–232

Pape I (2017) How nonwoven properties are influenced by moisture. Lenzinger Berichte 93:65–71

Rawal A, Moyo D, Soukupova V, Anandjiwala R (2007) Optimization of parameters in hydroentanglement process. J Ind Text 36:207–220

Roggenstein W (2011) Viscose fibres with new functional qualities. Lenzinger Berichte 89:72–77

Uusi-Tarkka EK (2016) Bio-based nonwoven fabric-like materials produced by paper machines. University of Boras, Swedish

Wang Y, De Assis T, Zambrano F, Pal L, Venditti R, Dasmohapatra S, Pawlak J, Gonzalez R (2019) Relationship between human perception of softness and instrument measurements. BioRes 14(1):780–795

Xiang P, Kuznetsov AV (2008) Simulation of shape dynamics of a long flexible fiber in a turbulent flow in the hydroentanglement process. Int Commun Heat Mass 35:529–534

Yu W (2006) Textile samples. China Textile Press, Beijing, pp 87–92

Yu W, Chu C (2003) Textile physics. Donghua University Press, Shanghai, pp 126–127

Zhang Y, Jin X (2018) The influence of pressure sum, fiber blend ratio, and basis weight on wet strength and dispersibility of wood pulp/Lyocell wetlaid/spunlace nonwovens. J Wood Sci 64:256–263

Zhang Y, Zhao Y, Latifi M, Wang R, Jin X (2018a) Investigation of the mechanical and dispersible properties of wood pulp/Danufil wetlaid nonwovens with/without hydroentanglement. J Text Inst 109:647–655

Zhang Y, Deng C, Wang Y, Huang C, Zhao Y, Jin X (2018b) A new dispersible moist wipe from wetlaid/spunlace nonwoven: development and characterization. J Ind Text 48:1136–1150

Zhang Y, Xu Y, Zhao Y, Huang C, Jin X (2019) Effects of short-cut fiber type and water-jet pressure sum on wet strength and dispersibility of wood pulp-based wetlaid/spunlace wipes. Euro J Wood Prod 77:33–43

Zwick KJ, Vogel NJ, Baker JK (2013) Dispersible moist wipe. Patent 063737AI,WO

Acknowledgements

The author(s) wish to express their sincere gratitude to Zhejiang Baoren Hezhong Nonwoven Co., Ltd for their support in providing the means for conducting experiments. This work was supported by the National Natural Science Foundation of China Youth Foud (Grant number 51903156), the Shaoxing University Research Foundation (Grant number 20185026) and the Research Project of Shaoxing University (Grant number 2018LG1005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Guo, K., Zhan, H. et al. Investigation of the wet strength and handle properties of wood pulp-based wetlaid/spunlace materials with different moisture contents. Eur. J. Wood Prod. 79, 1305–1314 (2021). https://doi.org/10.1007/s00107-021-01684-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01684-4