Abstract

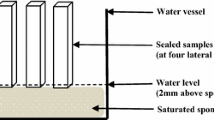

Large research work is currently being performed concerning different elaborated new wood protection methods. However, combining industrially well-approbated processes is also considered potentially quite promising and such approach is being actively studied. The objective of the present study was to investigate peculiarities of interaction between liquids and thermally modified (TM) birch wood (Betula spp.). This knowledge is essential for proper TM wood post-treatments involving its impregnation as well as for evaluation of potential wood moisture dynamics in outdoor applications. Changes caused by TM (150–170 °C) in a closed system under elevated pressure in wood wettability, permeability, liquid absorption capacity, and drying characteristics were evaluated. The results concerning absorption capacity, which is mainly related to wood anatomical features and is density-dependent, indicated reduced absorption capacity of TM wood compared with unmodified birch of similar density. Permeability, which characterises the ease with which liquid is transported through a wood porous system, was evaluated by capillary absorption tests through the samples’ tangential and radial surfaces. TM made birch wood less permeable through both surfaces as well as less anisotropic regarding transverse absorption rates. Moreover, TM also caused a decrease in drying rates for birch wood impregnated with water. Reduction in permeability influences the impregnation process of boards and no full saturation was detected for TM boards when applying an impregnation schedule providing complete saturation for unmodified boards. On the other hand, less water was absorbed by TM boards exposed to rain on outdoor weathering racks.

Similar content being viewed by others

References

Ahmed SA, Hansson L, Morén T (2013) Distribution of preservatives in thermally modified Scots pine and Norway spruce sapwood. Wood Sci Technol 47(3):499–513

Baysal E, Degirmentepe S, Toker H, Turkoglu T (2014) Some mechanical and physical properties of AD-KD 5 impregnated and thermally modified Scots pine wood. Wood Res 59(2):283–296

Boonstra MJ, Rijsdijk JF, Sander C, Kegel E, Tjeerdsma B, Militz H, Van Acker J, Stevens M (2006) Microstructural and physical aspects of heat treated wood. Part 2. Hardwoods. Maderas-Cienc Technol Wood 8(3):209–217

Candelier K, Hannouz S, Thévenon MF, Guibal D, Gérardin P, Pétrissans M, Collet R (2017) Resistance of thermally modified ash (Fraxinus excelsior L.) wood under steam pressure against rot fungi, soil-inhabiting micro-organisms and termites. Eur J Wood Prod 75(2):249–262

Chirkova J, Andersons B, Andersone I (2007) Study of the structure of wood-related biopolymers by sorption methods. Bioresources 4(3):1044–1057

Freeman M, McIntyre CR (2008) A comprehensive review of copper-based wood preservatives. For Prod J 58(11):6–27

Hakkou M, Pértrissans M, Zoulalian A, Gérardin P (2005) Investigations of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stabil 89:1–5

Hill CAS (2012) Wood modification: an update. Bioresources 6(2):918–919

Humar M, Lesar B (2009) Influence of dipping time on uptake of preservative solution, adsorption, penetration and fixation of copper-ethanolamine based wood preservatives. Eur J Wood Prod 67:265–270

Johansson D, Sehlstedt-Persson M, Morén T (2006) Effect of heat treatment on capillary water absorption of heat-treated pine, spruce and birch. In: Proceedings of the 5th IUFRO Symposium on Wood Structure and Properties ’06. Kurjatko S, Kúdela J, Lagaňa R (Eds), Sielnica, Slovenia. pp. 251–255

Kamdem DP, Pizzi A, Jermannaud A (2002) Durability of heat-treated wood. Holz Roh Werkst 60:1–6

Kocaefe D, Poncsak S, Doré G, Younsi R (2008) Effect of heat treatment on the wettability of white ash and soft maple by water. Holz Roh Werkst 66:355–361

Lande S, Høibø O, Larnøy E (2010) Variation in treatability of Scots pine (Pinus sylvestris) by the chemical modification agent furfuryl alcohol dissolved in water. Wood Sci Technol 44:105–118

Metsä-Kortelainen S, Viitanen H (2010) Effect of fungal exposure on the strength of thermally modified Norway spruce and Scots pine. Wood Mater Sci Eng 1:13–23

Metsä-Kortelainen S, Viitanen H (2012) Wettability of sapwood and heartwood of thermally modified Norway spruce and Scots pine. Eur J Wood Prod 70:135–139

Metsä-Kortelainen S, Antikainen T, Viitaniemi H (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170 °C, 190 °C, 210 °C and 230 °C. Holz Roh Werkst 64:192–197

Militz H, Altgen M (2014) Processes and properties of thermally modified wood manufactured in Europe Deterioration and Protection of Sustainable Biomaterials. ACS Symp Ser 1158:269–285

Murmanis L, Chudnoff M (1979) Lateral flow in beech and birch as revealed by the electron micro-scope. Wood Sci Technol 13:79–87

Nussbaum RM (1999) Natural surface inactivation of Scots pine and Norway spruce evaluated by contact angle measurements. Holz Roh Werkst 57:419–424

Pfriem A (2011) Alteration of water absorption coefficient of spruce (Picea abies (L.) Karst.) due to thermal modification. Drvna Industrija 62(4):311–313

Rapp AO, Peek RD, Sailer M (2000) Modelling the moisture induced risk of decay for treated and untreated wood above ground. Holzforschung 54:111–118

Rhatigan R, Freitag C, El-Kasmi S, Morrell JJ (2004) Preservative treatment of Scots pine and Norway spruce. For Prod J 54(10):91–94

Salman S, Pétrissans A, Thévenon MF, Dumarçay S, Gérardin P (2016) Decay and termite resistance of pine blocks impregnated with different additives and subjected to heat treatment. Eur J Wood Prod 74(1):37–42

Siau JF (1984) Transport Processes in Wood. Springer, Berlin

Terziev N (1995) Migration of low-molecular sugars and nitrogenous compounds in Pinus sylvestris L. during kiln and air drying. Holzforschung 49:565–574

Thomas RJ (1976) Anatomical features affecting liquid penetrability in three hardwood species. Wood Fiber 7(4):256–263

Turkoglu T, Baysal E, Yuksel M, Peke H, Sacl C, Kureli I, Toker H (2016) Mechanical properties of impregnated and heat treated oriental beech wood. Bioresources 11(4):8285–8296

Van Acker J, Van den Bulcke J, De Windt I, Colpaert S, Li W (2015) Moisture Dynamics of modified wood and the relevance towards decay resistance. In: Proceedings of the eight European conference on wood modification, October 26–27, 2015, Helsinki, Finland. 44–55

Wang W, Zhu Y, Cao J (2013) Evaluation of copper leaching in thermally modified southern yellow pine wood impregnated with ACQ-D. Bioresources 8(3):4687–4701

Widmann R, Fernandez-Cabo JL, Steiger R (2012) Mechanical properties of thermally modified beech timber for structural purposes. Eur J Wood Prod 70(6):775–784

Willems W, Altgen M, Militz H (2015) Comparison of EMC and durability of heat treated wood from high versus low water vapour pressure reactor systems. Int Wood Prod J 6(1):21–26

Winandy JE, Rowell RM (2013) Chemistry of wood strength. In: Rowell RM (ed) Handbook of wood chemistry and wood composites, 2nd edn. Taylor & Francis Group, Boca Raton, pp 413–455

Zauer M, Pfriem A, Wagenführ A (2013) Toward improved understanding of the cell-wall density and porosity of wood determined by gas pycnometry. Wood Sci Technol 47(6):1197–1211

Acknowledgements

The authors gratefully acknowledge the financial support by the European Regional Development Fund project No. 1.1.1.1/16/A/133.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cirule, D., Verovkins, A., Andersone, I. et al. Thermally modified birch wood interaction with liquids. Eur. J. Wood Prod. 78, 849–857 (2020). https://doi.org/10.1007/s00107-020-01568-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01568-z