Abstract

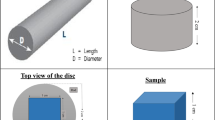

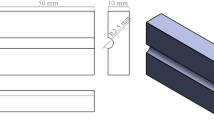

Low carbon steel materials are commonly used for numerous applications for both scientific as well as practical purposes. These materials can be easily welded and forged and shaped. The two most common grades of commercially available low carbon steel are AISI 1020 and 304 grades. They are used as substrates for coating thin films to improve their performance. There are both low carbon, but differ substantially in their chemical compositions, structure, mechanical properties, and also their corrosion performance. The selection of the material for different applications usually involves an initial assessment of their structure–property correlation. Although there are a number of articles that have evaluated performance and characterized their properties of these commercially available materials for their applications, the structure–property–performance correlation of the materials is not available. This work correlates the chemical composition, microstructure, mechanical properties, and corrosion performance (by construction of Tafel plots through potentiodynamic polarization tests) of AISI 1020 and 304 steel and compares them. The work shows that while the mechanical properties of AISI 1020 are superior, the corrosion performance in 3.5 wt% NaCl solution is actually poor. The corrosion degradation AISI 1020 is observed to occur due to pitting corrosion aggravated by microcracks. The improved corrosion performance of AISI 304 steel is due to the presence of appreciable amounts of chromium and nickel in its chemical composition.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chuaiphan W, Somrerk CA, Niltawach S, Sornil B (2012) Appl Mech Mater 268–270:283–290. https://doi.org/10.4028/www.scientific.net/AMM.268-270.283

Masanta M, Shariff SM, Roy Choudhury A (2011) Wear 271(7–8):1124–1133. https://doi.org/10.1016/j.wear.2011.05.009

Zhang J, Li S, Chenfeng L, Sun C, Shuai P, Xue Q, Lin Y, Huang M (2019) Surf Coat Technol 364(25):265–272. https://doi.org/10.1016/j.surfcoat.2019.02.085

Ye Y, Zhang D, Liu T, Liu Z, Pub J, Liu W, Zhao H, Li X, Wang L (2019) Carbon 142:164–176. https://doi.org/10.1016/j.carbon.2018.10.050

Zhang D, Wang M, Jiang N, Liu Y, Yu X, Zhang H (2020) Int J Electrochem Sci 15(2):4117–4126. 10.20962020.05.25

Malik J, Toor IH, Ahmed WH, Gasem ZM, Habib MA, Ben-Mansour R, Badr HM (2014) Int J Electrochem Sci 9:6765–6780

Mohammadi F (2011) Erosion-corrosion of 304 stainless steel. Doctoral thesis, University of Alberta

Cao C, Cheng J (2018) Surf Coat Technol 349:296–302. https://doi.org/10.1016/j.surfcoat.2018.06.001

Alibakhshi E, Akbarian M, Ramezanzadeh M, Ramezanzadeh B, Mahdavian M (2018) Prog Org Coat 123:190–200. https://doi.org/10.1016/j.porgcoat.2018.07.008

Martinez MA, Abenojar J, Bahrami M, Velasco F (2021) Metals 11:1007. https://doi.org/10.3390/met11071007

Sathish Sharma G, Sugavaneswaran M, Vijayalakshmi U, Prakash R (2019) Ceram Int 45(10):13456–13463. https://doi.org/10.1016/j.ceramint.2019.04.046

Lee H-S, Singh JK (2019) Corros Sci 146:254–268. https://doi.org/10.1016/j.corsci.2018.10.035

Bijalwan P, Kumar A, Nayak SK, Banerjee A, Dutta M, Laha T (2019) J Alloy Compd 796(5):47–54. https://doi.org/10.1016/j.jallcom.2019.05.046

Bartkowski D, Bartkowska A, Jurči P (2021) Opt Laser Technol 136:106784. https://doi.org/10.1016/j.optlastec.2020.106784

Zamani MR, Meymiana, Ghaffarinej A, Fazli R, Mehr AK (2020) Colloids Surf A Physicochem Eng Aspects 593:124617. https://doi.org/10.1016/j.colsurfa.2020.124617

Calderon S, Almeida Alves CF, Manninen NK, Cavaleiro A, Carvalho S (2019) Coatings 9(10):682. https://doi.org/10.3390/coatings9100682

Siddiqui AR, Maurya R, Katiyar PK, Balani K (2020) Surf Coat Technol 404:126421. https://doi.org/10.1016/j.surfcoat.2020.126421

Chanda UK, Behera A, Roy S, Pati S (2018) Int J Hydrogen Energy 43(52):23430–23440. https://doi.org/10.1016/j.ijhydene.2018.10.218

Palani V, Kumar A, Vijaya Kumar KR, Kumaran P (2021) Int J Precis Eng Manuf 22:365–372. https://doi.org/10.1007/s12541-020-00458-x

He S, Qiu Y, Sun Y, Zhang Z, Cheng J, Gao C, Zhao Z (2020) Int J Greenhouse Gas Control 94:102931. https://doi.org/10.1016/j.ijggc.2019.102931

Mandal P, Usha Kiran N, Chanda UK, Pati S, Roy S (2021) SN Appl Sci 3:715. https://doi.org/10.1007/s42452-021-04710-5

Abioyeab TE, Ariwoolac OE, Ogedengbec TI, Farayibib PK, Gbadeyan OO (2019) Mater Today Proc 17(3):871–877. https://doi.org/10.1016/j.matpr.2019.06.383

Bermeo F, Quintana JP, Kleiman A, Sequeda F, Márquez A (2017) J Phys Conf Ser 792:012061. https://doi.org/10.1088/1742-6596/792/1/012061

Vijayanand P, Kumar A, Vijaya Kumar KR, Hussain N, Kumaran P, Arungalai Vendan S (2017) Rasayan J Chem 10(2):652–664. https://doi.org/10.7324/RJC2017.1021707

Bonetti I, dos S de EA, da Costa CE, Paredes RSC, Sucharski GB, da Costa EM, Franco E, Milan JCG (2019) Mater Res Express 6:086530

Jeyaprakash N, Duraiselvam M, Raju R (2018) Modelling of Cr3C2–25% NiCr laser alloyed cast iron in high temperature sliding wear condition using response surface methodology. Arch Metall Mater 63(3):1303–1315

Palanisamy D, Manikandan N, Ramesh R, Devaraju A, ArulKirubakaran D (2020) Development of neural network models for wire electrical discharge machining of Haste alloy. Mater Today Proc 39(1):438–445

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Roy, S., Nayak, B.B., Sahu, S. (2023). Investigation on the Microstructure–Corrosion Correlation of Commercially Available AISI 1020 and 304 Steel. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds) Recent Advances in Materials Processing and Characterization. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-5347-7_14

Download citation

DOI: https://doi.org/10.1007/978-981-19-5347-7_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5346-0

Online ISBN: 978-981-19-5347-7

eBook Packages: EngineeringEngineering (R0)