Abstract

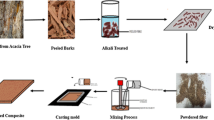

Biofibers and Agro-waste in polymer matrix materials are attracting augmented deliberation because of ecological concerns and the acknowledgment that worldwide oil assets are limited. Natural fiber-based hybrid composites were the best choice for automobile industry for interior and exterior parts, bearings, door linings, etc., since they were searching for new ecofriendly material which reduces the cost and weight. The aim of the present work is to conduct an experimental study based on the design of experiments (DOE) of abrasive wear property of Agro-waste areca husk fiber (AHF) reinforced epoxy composites by varying various parameters such as weight % of fiber (0, 7, 14, 21, 28), sliding distance (314.16, 471.24, 628.32 m) and applied load (5, 7.5, 10, 15 N) using the pin-on-disk method. The wear experiments were carried out as per full factorial design of experiment, and response surface methodology (RSM) was adopted to develop an empirical model for the true response surface. Analysis of variance (ANOVA) test is used to check the adequacy and thus estimate the optimum process parameters for the AHF composite for specific wear rate. The optimum value obtained for specific wear rate was 3.87 × 10–11 m3/Nm which when the applied load = 15 N, sliding distance = 628.32 m and the wt% of fiber reinforcement = 15.27%, respectively. FTIR was conducted to analyze the structural modifications caused by NaOH treatment of AHF fibers. Results indicate that incorporation of areca husk fibers considerably enhanced the abrasion properties of AHF composites and can be used for different tribological applications. The major wear mechanisms were revealed by worn surface profile study using SEM (ZEISS EVO-18), and it also shows that chemical surface treatment (5% NaOH) improves the adhesion between fibers and matrix which significantly influences the abrasive wear properties of fabricated composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Singha NR, Mahapatra M, Karmakar M, Chattopadhyay PK (2019) Processing, characterization and application of natural rubber based environmentally friendly polymer composites. https://doi.org/10.1007/978-3-030-05399-4_29

Kim YK, Chalivendra V (2020) Natural fibre composites (NFCs) for construction and automotive industries. Elsevier. https://doi.org/10.1016/b978-0-12-818782-1.00014-6

Keya KN, Kona NA, Koly FA, Maraz KM, Islam MN, Khan RA (2019) Natural fiber reinforced polymer composites: history, types, advantages, and applications. Mater Eng Res 1:69–87

Raj SSR, Dhas JER, Jesuthanam CP (2020) Challenges on machining characteristics of natural fiber-reinforced composites—a review. J Reinf Plast Compos. https://doi.org/10.1177/0731684420940773

Adekomaya O, Jamiru T, Sadiku R, Huan Z (2016) A review on the sustainability of natural fiber in matrix reinforcement—a practical perspective. J Reinf Plast Compos 35:3–7. https://doi.org/10.1177/0731684415611974

Hasan KMF, Horváth PG, Alpár T (2020) Potential natural fiber polymeric nanobiocomposites: a review. Polymers (Basel) 12. https://doi.org/10.3390/POLYM12051072

Neves ACC, Rohen LA, Mantovani DP, Carvalho JPRG, Vieira CMF, Lopes FPD et al (2019) Comparative mechanical properties between biocomposites of epoxy and polyester matrices reinforced by hemp fiber. J Mater Res Technol 9:1296–1304. https://doi.org/10.1016/j.jmrt.2019.11.056

Kumar R, Ul Haq MI, Raina A, Anand A (2019) Industrial applications of natural fibre-reinforced polymer composites–challenges and opportunities. Int J Sustain Eng 12:212–220. https://doi.org/10.1080/19397038.2018.1538267

Lucintel (2015) Growth opportunities in the global natural fiber composites market

Mellinas C, Ramos M, Jiménez A, Garrigós MC (2020) Recent trends in the use of pectin from Agro-waste residues as a natural-based biopolymer for food packaging applications. Materials (Basel) 13. https://doi.org/10.3390/ma13030673

Chand N, Sharma P, Fahim M (2010) Tribology of maleic anhydride modified rice-husk filled polyvinylchloride. Wear 269:847–853. https://doi.org/10.1016/j.wear.2010.08.014

Diacono M, Persiani A, Testani E, Montemurro F, Ciaccia C (2019) Recycling agricultural wastes and by-products in organic farming: biofertilizer production, yield performance and carbon footprint analysis. Sustain 11:1–17. https://doi.org/10.3390/su11143824

Dungani R, Karina M, Subyakto, Sulaeman A, Hermawan D, Hadiyane A (2016) Agricultural waste fibers towards sustainability and advanced utilization: a review. Asian J Plant Sci 15:42–55. https://doi.org/10.3923/ajps.2016.42.55

Prithivirajan R, Jayabal S, Bharathiraja G (2015) Bio-based composites from waste agricultural residues: mechanical and morphological properties. Cellul Chem Technol 49:65–68

Akampumuza O, Wambua PM, Ahmed A, Li W, Qin XH (2017) Review of the applications of biocomposites in the automotive industry. Polym Compos 38:2553–2569. https://doi.org/10.1002/pc.23847

Gao M, Shih CC, Pan SY, Chueh CC, Chen WC (2018) Advances and challenges of green materials for electronics and energy storage applications: from design to end-of-life recovery. J Mater Chem A 6:20546–20563. https://doi.org/10.1039/C8TA07246A

Verma D, Fortunati E (2019) Biopolymer processing and its composites: an introduction. Elsevier. https://doi.org/10.1016/B978-0-08-102426-3.00001-1

Ibrahem RA (2015) Effect of date palm seeds on the tribological behaviour of polyester composites under different testing conditions. J Mater Sci Eng 04. https://doi.org/10.4172/2169-0022.1000206

Vishal K, Rajkumar K, Annamalai VE (2021) Wear and tribofilm characterization of bamboo CNT (B-CNT)-peek composite with incremental blending of submicron synthetic diamond particles. Wear 466–467:203556. https://doi.org/10.1016/j.wear.2020.203556

Binoj JS, Raj RE, Hassan SA, Mariatti M, Siengchin S, Sanjay MR (2020) Characterization of discarded fruit waste as substitute for harmful synthetic fiber-reinforced polymer composites. J Mater Sci 55:8513–8525. https://doi.org/10.1007/s10853-020-04620-8

Dhanalakshmi S, Ramadevi P, Basavaraju B (2015) Areca fiber reinforced epoxy composites: effect of chemical treatments on impact strength. Orient J Chem 31:763–769. https://doi.org/10.13005/ojc/310218

Das P (2019) Underutilized Meghalyan arecanut husk waste fiber for development of nonwoven textile material. Int J Pure Appl Biosci 7:563–567. https://doi.org/10.18782/2320-7051.7580

Ganeshamurthy A, Kalaivanan D, Rupa T, Manjunath B (2019) An assessment of the fertilizer needs of horticultural crops in India. Indian J Fertil 15:286–295

Raj SS (2019) Optimization of fabrication parameters on hybrid fibre reinforced polymer composite by ANN design. Innov Power Adv Comput Technol 2019:1–4. https://doi.org/10.1109/i-PACT44901.2019.8960244

Kumar NGS, Prabhu TR, Mishra RK, Eswaraprasad N, Shankar GSS, Basavarajappa S (2018) Analysis of dry sliding wear behavior of the nano composites using statistical methods with an emphasis on temperature effects. Meas J Int Meas Confed 128:362–376. https://doi.org/10.1016/j.measurement.2018.06.064

Yin Z, Peng Y, Li T, Zhu Z, Yu Z, Wu G (2020) Effect of the operating parameter and grinding media on the wear properties of lifter in ball mills. Proc Inst Mech Eng Part J J Eng Tribol 234:1061–1074. https://doi.org/10.1177/1350650119894492

Sajeeb Rahiman AH, Robinson Smart DS, Wilson B, Ebrahim I, Eldhose B, Mathew B, Murickan RT (2020) Dry sliding wear analysis OF Al5083/CNT/Ni/MoB hybrid composite using DOE Taguchi method. Wear, 460–461

Myers RH, Montgomery DC, Geoffrey Vining G, Borror CM, Kowalski SM (2004) Response surface methodology: a retrospective and literature survey. J Qual Technol 36:53–78. https://doi.org/10.1080/00224065.2004.11980252

Chelladurai SJS, Murugan K, Ray AP, Upadhyaya M, Narasimharaj V, Gnanasekaran S (2020) Optimization of process parameters using response surface methodology: a review. Mater Today Proc 37:1301–1304. https://doi.org/10.1016/j.matpr.2020.06.466

Kamath SS, Sampathkumar D, Bennehalli B (2017) A review on natural areca fibre reinforced polymer composite materials. Cienc e Tecnol Dos Mater 29:106–128. https://doi.org/10.1016/j.ctmat.2017.10.001

Ba D, Boyaci IH (2007) Modeling and optimization i: usability of response surface methodology. J Food Eng 78:836–845. https://doi.org/10.1016/j.jfoodeng.2005.11.024

Weissman SA, Anderson NG (2015) Design of experiments (DoE) and process optimization. A review of recent publications. Org Process Res Dev 19:1605–1633. https://doi.org/10.1021/op500169m

Enis IY, Sezgin H, Sadikoglu TG (2018) Full factorial experimental design for mechanical properties of electrospun vascular grafts. J Ind Text 47:1378–1391. https://doi.org/10.1177/1528083717690614

Saravanan V, Thyla PR, Balakrishnan SR (2015) Optimization of wear behavior on cenosphere -aluminium composite. Korean J Mater Res 25:322–329. https://doi.org/10.3740/MRSK.2015.25.7.322

Morshed MN, Pervez MN, Behary N, Bouazizi N, Guan J, Nierstrasz VA (2020) Statistical modeling and optimization of heterogeneous Fenton-like removal of organic pollutant using fibrous catalysts: a full factorial design. Sci Rep 10:1–14. https://doi.org/10.1038/s41598-020-72401-z

Piepho HP, Edmondson RN (2018) A tutorial on the statistical analysis of factorial experiments with qualitative and quantitative treatment factor levels. J Agron Crop Sci 204:429–455. https://doi.org/10.1111/jac.12267

Faraway JJ (2002) Practical regression and Anova using R

Salguero J, Vazquez-Martinez JM, Del Sol I, Batista M (2018) Application of Pin-On-Disc techniques for the study of tribological interferences in the dry machining of A92024–T3 (Al-Cu) alloys. Materials (Basel) 11:1–11. https://doi.org/10.3390/ma11071236

Dey A, Mandal S, Bhandari S, Pal C, Orasugh JT, Chattopadhyay D (2020) Characterization methods. In: Fiber-reinforced nanocomposites fundamentals and applications. Micro and nano technologies. Elsevier, Amsterdam, Netherlands, pp 7–67

Kumar S, Mer KKS, Gangil B, Patel VK (2019) Synergy of rice-husk filler on physico-mechanical and tribological properties of hybrid Bauhinia-vahlii/sisal fiber reinforced epoxy composites. J Mater Res Technol 8:2070–2082. https://doi.org/10.1016/j.jmrt.2018.12.021

Emerson RW (2017) ANOVA and t-tests. J Vis Impair Blind 111:193–196. https://doi.org/10.1177/0145482x1711100214

Montgomery DC, Peck EA, Vining GG (2012) Introduction to linear regression analysis. Wiley, Hoboken, NJ

Larsen WA, McCleary SJ (1972) The use of partial residual plots in regression analysis. Technometrics 14:781–790. https://doi.org/10.1080/00401706.1972.10488966

Gohil P, Patel K, Chaudhary V (2019) Natural fiber-reinforced polymer composites: a comprehensive study on machining characteristics of hemp fiber-reinforced composites. Elsevier. https://doi.org/10.1016/B978-0-08-102426-3.00002-3

Antony J. A Systematic Methodology for Design of Experiments. Second Edi. Elsevier Ltd; 2014. https://doi.org/10.1016/b978-0-08-099417-8.00004-3.

Chandramohan D, Ravikumar L, Sivakandhan C, Murali G, Senthilathiban A (2018) Review on tribological performance of natural fibre-reinforced polymer composites. J Bio-Tribo-Corrosion 4. https://doi.org/10.1007/s40735-018-0172-x

Madhu P, Sanjay MR, Senthamaraikannan P, Pradeep S, Saravanakumar SS, Yogesha B (2019) A review on synthesis and characterization of commercially available natural fibers: Part II. J Nat Fibers 16:25–36. https://doi.org/10.1080/15440478.2017.1379045

Ng HM, Saidi NM, Omar FS, Ramesh K, Ramesh S, Bashir S (2018) Thermogravimetric analysis of polymers. Encycl Polym Sci Technol, 1–29. https://doi.org/10.1002/0471440264.pst667

Sumithra H, Sidda RB (2018) A review on tribological behaviour of natural reinforced composites. J Reinf Plast Compos 37:349–353. https://doi.org/10.1177/0731684417747742

Latif R, Wakeel S, Khan NZ, Noor Siddiquee A, Lal Verma S, Akhtar KZ (2019) Surface treatments of plant fibers and their effects on mechanical properties of fiber-reinforced composites: a review. J Reinf Plast Compos 38:15–30. https://doi.org/10.1177/0731684418802022

Ashok RB, Srinivasa CV, Basavaraju B (2018) A review on the mechanical properties of areca fiber reinforced composites. Sci Technol Mater. https://doi.org/10.1016/j.stmat.2018.05.004

Dhanalakshmi S, Ramadevi P, Basavaraju B (2017) A study of the effect of chemical treatments on areca fiber reinforced polypropylene composite properties. Sci Eng Compos Mater 24:501–520. https://doi.org/10.1515/secm-2015-0292

Sankar I, Ravindran D (2016) Fiber loading and treatment effects on dry sliding wear of Palmyra fruit fiber composites. Sci Eng Compos Mater 23:217–226. https://doi.org/10.1515/secm-2014-0101

Rajeshkumar G (2020) Effect of sodium hydroxide treatment on dry sliding wear behavior of Phoenix sp. fiber reinforced polymer composites. J Ind Text. https://doi.org/10.1177/1528083720918948

Vigneshwaran S, Uthayakumar M, Arumugaprabu V, Deepak Joel Johnson R (2018) Influence of filler on erosion behavior of polymer composites: a comprehensive review. J Reinf Plast Compos 37:1011–1119. https://doi.org/10.1177/0731684418777111

Suresh S, Sudhakara D, Vinod B (2020) Investigation on Industrial waste eco-friendly natural fiber-reinforced polymer composites. J Bio-Tribo-Corrosion 6:1–14. https://doi.org/10.1007/s40735-020-00339-w

Ahmed A (1989) Polymer tribology, vol C29. https://doi.org/10.1533/9781782421788.1

Correa CE, Betancourt S, Vázquez A, Gañan P (2015) Wear resistance and friction behavior of thermoset matrix reinforced with Musaceae fiber bundles. Tribol Int 87:57–64. https://doi.org/10.1016/j.triboint.2015.02.015

Yousif BF, Nirmal U, Wong KJ (2010) Three-body abrasion on wear and frictional performance of treated betelnut fibre reinforced epoxy (T-BFRE) composite. Mater Des 31:4514–4521. https://doi.org/10.1016/j.matdes.2010.04.008

Barkoula NM, Alcock B, Cabrera NO, Peijs T (2008) Flame-retardancy properties of intumescent ammonium poly(phosphate) and mineral filler magnesium hydroxide in combination with graphene. Polym Polym Compos 16:101–113

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Raj, S.S., Edwin Raja Dhas, J., Harish Kumar, B. (2023). Optimization and Analysis of Abrasive Wear of Agro-waste Fiber Reinforced Composites by RSM Design Matrix. In: Rajkumar, K., Jayamani, E., Ramkumar, P. (eds) Recent Advances in Materials Technologies. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-3895-5_9

Download citation

DOI: https://doi.org/10.1007/978-981-19-3895-5_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-3894-8

Online ISBN: 978-981-19-3895-5

eBook Packages: EngineeringEngineering (R0)