Abstract

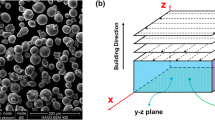

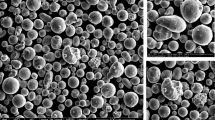

To examine the influence of the building directions on surface micro-structure and tribological characteristics of stainless steel 316L samples generated using selective laser melting (SLM) technology, parts were produced in three distinct building orientations (0°, 45°, 90°). The impact of construction orientation on stainless steel microstructure, mechanical characteristics, and machinability was examined. Scanning electron microscopy (SEM) was used to examine the microstructure of SLM samples. In the X-ray diffraction (XRD) patterns of the SLM samples, only, the FCC austenite phase was found. The γ-Ni phase's lattice constant in the SLM 45°sample was the lowest of these SLM samples. The surface roughness of the SLM 45° specimen was the highest compared to the other sections, while the surface roughness of the SLM 0° sample was the lowest. Large dendritic grains were uniformly distributed in the SLM 0° sample, but the roughest dendritic grains were produced in the SLM 45° sample. In addition, the SLM 0° specimen had the best tribological results.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Yap CY, Chua CK, Dong ZL, Liu ZH, Zhang DQ, Loh LE, Sing SL (2015) Review of selective laser melting: materials and applications. Appl Phys Rev 2 (2015)

Yasa E, Kruth J (2011) Application of laser re-melting on selective laser melting parts. Adv Prod Eng Manag 6:259–270

Emmelmann, (2021) Material modeling of Ti6Al4V alloy processed by laser powder bed fusion for application in macro-scale process simulation. Mater Sci Eng 814:141237

Tucho WM, Lysne VH, Sjolyst-Kverneland A, Hansen V (2018) Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. Alloy Compd 740:910–925

Wei Y, Chen G, Li W, Zhou Y, Nie Z, Xu J, Zhou W (2021) Micro selective laser melting of SS316L: single tracks, defects, microstructures and thermal/mechanical properties. Opt Laser Technol 145:107469

Gu D, Shen Y (2009) Balling phenomena in direct laser sintering of stainless-steel powder: metallurgical mechanisms and control methods. Mater Des 30:2903–2910

Yadroitsev I, Smurov I (2010) Selective laser melting technology: from the single laser melted track stability to 3D parts of complex shape. Phys Procedia 5:551–560

Gonzalez JA, Mireles J, Stafford SW, Perez MA, Terrazas CA, Wicker RB (2019) Characterization of Inconel 625 fabricated using powder-bed-based additive manufacturing technologies. J Mater Process Technol 264:200–210

Rashid R, Masood SH, Ruan D, Palanisamy S, Rahman Rashid RA, Elambasseril J, Brandt M (2018) Effect of energy per layer on the anisotropy of selective laser melted AlSi12 aluminium alloy. Addit Manuf 22:426–439

Yen Y, Su J, Huang D (2008) Phase equilibria of the Fe-Cr-Ni ternary systems and interfacial reactions in Fe-Cr alloys with Ni substrate. J Alloy Compd 457:270–278

Dinda GP, Dasgupta AK, Mazumder J (2009) Laser aided direct metal deposition of Inconel 625 superalloy: microstructural evolution and thermal stability. Mater Sci Eng A 509:98–104

Alexander L, Klue HP (1989) Basic aspects of X-ray absorption in quantitative diffraction analysis of powder mixtures. Powder Diffr 4:66–69

Cieslak MJ, Headley TJ, Kollie T, Romig AD (1988) Melting and solidification study of Alloy 625. Metall Trans A 19:2319–2331

Das S (2003) Physical aspects of process control in selective laser sintering of metals. Adv Eng Mater 5:701–711

Gholipour A, Shamanian M, Ashrafizadeh F (2011) Microstructure and wear behavior of stellite 6 cladding on 17–4 PH stainless steel. J Alloys Compd 509:4905–4909

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ramar, M., Kanagasabapathy, H., Rajakarunakaran, S. (2023). The Influence of Building Orientations on the Mechanical Characteristics of Selective Laser-Melting SS316L. In: Rajkumar, K., Jayamani, E., Ramkumar, P. (eds) Recent Advances in Materials Technologies. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-3895-5_46

Download citation

DOI: https://doi.org/10.1007/978-981-19-3895-5_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-3894-8

Online ISBN: 978-981-19-3895-5

eBook Packages: EngineeringEngineering (R0)