Abstract

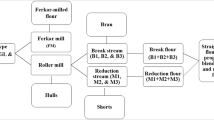

Pulses or grain legumes are dry edible seed with the pod. Pulses contain essential micronutrients, complex carbohydrates, and dietary fiber and are commonly referred as poor man’s meat because of the rich source of protein at low cost. This chapter discusses the nutrient potential of pulses and the various unit operations involved in processing. The chapter summarizes the major factors that can affect the milling efficiency, and also the effect of milling on the composition, functional properties, cooking quality, etc. of pulses. Case studies of important pulses like chickpea, pigeon pea, and black gram are also explained with process flow diagrams. The estimation of milling efficiency in terms of dehulling index (DI), dehulling efficiency (DE), split yield, and percentage of brokens is worked out using examples. The quality characteristics and functional properties of pulses are also discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

FAO (Food and Agriculture Organization of the United Nations). (2021). Definition and classification commodities, pulses and derived products. Retrieved 16 February, 2021, from http://www.fao.org/waicent/faoinfo/economic/faodef/fdef04e.htm#4.01

Swaminathan, M. (1974). Pulses: Essentials of food and nutrition (pp. 355–356). Ganesh and Co..

Ofuya, Z. M., & Akhidue, V. (2005). Role of pulses in human nutrition. Journal of Applied Sciences and Environmental Management, 9, 99–104.

De Angelis, D., Pasqualone, A., Allegretta, I., Porfido, C., Terzano, R., Squeo, G., & Summo, C. (2021). Antinutritional factors, mineral composition and functional properties of dry fractionated flours as influenced by the type of pulse. Heliyon, 7(2), e06177.

Asif, M., Rooney, L. W., Ali, R., & Riaz, M. N. (2013). Application and opportunities of pulses in food system: A review. Critical Reviews in Food Science and Nutrition, 53(11), 1168–1179.

Ofuya, Z. M., & Akhidue, V. (2005). The role of pulses in human nutrition: A review. Journal of Applied Sciences and Environmental Management, 9(3), 99–104.

Gopalan, C., Rama Sastri, B. V., & Balasubramanian, S. C. (1989). Nutritive value of Indian foods. National Institute of Nutrition, ICMR.

Bhagyawant, S. S. (2013). Antinutritional factors in pulses and their diversity. Innovare Journal of Food Science, 1(1), 27–29.

Marquart, R. R., Ward, A. T., Campbell, L. D., & Cansfield, P. E. (1977). Purification, identification and characterization of growth inhibitor in faba beans (vicia faba, L var minor). Journal of Nutrition, 107, 1313–1324.

Grant, G., & van Drtessche, E. (1993). Legume lectins physicochemical and nutritional properties. In A. F. van der Poel, J. Huisman, & H. S. Sam (Eds.), Recent advances of research in ant-nutritional factors in legume seeds (pp. 219–234). Wagenmgen Press.

Rao, P. U., & Deosthale, Y. G. (1982). Tannin contents of pulses: Varietal differences and effect of cooking and germination. Journal of the Science of Food and Agriculture, 33, 1013–1016.

Jood, S., Chauhan, B. M., & Kapoor, A. C. (1987). Polyphenols of chickpea and blackgram as affected by domestic processing and cooking methods. Journal of the Science of Food and Agriculture, 39(2), 145–150.

Srivastava, R. P., & Srivastava, G. K. (2002). Indian Journal of Agricultural Biochemistry, 15, 33.

Rao, S. L. N., Malathi, K., & Sharma, P. S. (1969). Lathyrism World Review of Nutrition and Diet, 10, 214.

Chai, W., & Liebman, M. (2005). Oxalate content of legumes, nuts, and grain-based flours. Journal of Food Composition and Analysis, 18, 723–729.

Alonso, R., Aguirre, A., & Marzo, F. (2000). Effect of extrusion and traditional processing methods on antinutrients and invitro digestibility of protein and starch in faba and kidney beans. Food Chemistry, 68, 159–165.

Alonso, R., Orue, E., & Marzo, F. (1998). Effect of extrusion and conventional processing on protein and antinutritional factor content in pea seeds. Food Chemistry, 63, 505–512.

Kataria, A., Chauhan, B. M., & Gandhi, S. (1988). Effect of domestic processing and cooking on antinutrients of black gram. Food Chemistry, 30, 149–156.

El-hady, E. A. A., & Habiba, R. A. (2003). Effect of soaking and extrusion conditions on antinutrients and protein digestibility of legume seeds. LWT- Food Science and Technology, 36, 285–293.

Wang, N., Hatcher, D. W., Tyler, R. T., Toews, R., & Gawalko, E. J. (2001). Effect of cooking on the composition of beans (Phaseolus vulgaris L) and chickpeas (Cicer arietinum L) q. Food Research International, 43, 589–594.

Pasqualone, A., Costantini, M., Coldea, T. E., & Summo, C. (2020). Use of legumes in extrusion cooking: A review. Food, 9(7), 958.

Patil, R. T., & Sokhansanj, S. (2003). Dehulling and splitting pulses. In H. S. Ramaswamy, G. S. V. Raghavan, A. Chakravert, & A. S. Majumdar (Eds.), Handbook of postharvest technology (pp. 397–426). CRC Press.

Chakraverty, A. (1988). Post-harvest technology of cereals, pulses and oilseeds. IBH Publishing Company.

Reichert, R. D., Tyler, R. T., York, A. E., Schwab, D. J., Tatarynovich, J. E., & Mwassaru, M. A. (1986). Description of a production model of the tangential abrasive dehulling device and its application to breeders’ samples. Cereal Chemistry, 63(3), 201–207.

Chakraverty, A. (2003). Post harvest technology of cereals, pulses and oilseeds (1st ed.). IBH.

Lal, R. R., & Verma, P. (2007). Post-harvest management of pulses. Indian Institute of Pulses Research.

Goyal, R. K., Ilyas, S. M., Wanjari, O. D., Vishwakarma, R. K., Manikantan, M. R., Mridula, D. Pulse Milling Technologies, Central Institute of Post harvest Engineering and Technology, Ludhiana.

Deorukhkar, A., & Ananthanarayan, L. (2021). Effect of thermal processing methods on flavonoid and isoflavone content of decorticated and whole pulses. Journal of Food Science and Technology, 58(2), 465–473.

Kate, A. E., & Giri, S. K. (2020). Mass transfer dynamics of simultaneous water gain and solid loss during soaking of pigeon pea grains. Journal of Food Science, 85(10), 3406–3414.

Wood, J., & Malcolmson, L. (2011). Pulse milling technologies. In B. K. Tiwari, A. Gowen, & B. Mckenna (Eds.), Pulse foods (pp. 193–221). Academic Press. https://doi.org/10.1016/B978-0-12-382018-1.00008-3

Ikebudu, J. A., Sokhansanj, S., Tyler, R. T., Milne, B. J., & Thakor, N. S. (2000). Grain conditioning for dehulling of canola. Canadian Agricultural Engineering, 42, 4.1–4.13.

Ehiwe, A. O. F., & Reichert, R. D. (1987). Variability in dehulling quality of cowpea, pigeon pea, and mung bean cultivars determined with the tangential abrasive dehulling device. Cereal Chemistry, 64, 86–90.

Burridge, P., Hensing, A., & Petterson, D. (2001). Australian pulse quality laboratory manual. SARDI Grain Laboratory for GRDC.

FCI. (2016). Food Corporation of India, Quality specification for procurement of Pulses under PSF during Rabi Marketing season 2016-17. Retrieved from https://fci.gov.in/app2/webroot/upload/Quality/revised%20specifications%20chana%20and%20masur%2014.4.16.pdf

FSSR. (2010). Food safety and standard regulations. https://old.fssai.gov.in/Portals/0/Final_Regulations_2010.pdf

Mahanta, B., Manhot, N., Deka, M., & Singh, V. (2020). Weaning foods: Various methods of preparations focusing on traditional steps. Indian Journal of Agricultural Biochemistry, 33(1), 11–19.

Lopes, M., Pierrepont, C., Duarte, C. M., Filipe, A., Medronho, B., & Sousa, I. (2020). Legume beverages from chickpea and lupin, as new milk alternatives. Food, 9(10), 1458.

Tharanathan, R. N., & Mahadevamma, S. (2003). Grain legumes - A boon to human nutrition. Trends in Food Science and Technology, 14, 507–518. https://doi.org/10.1016/j.tifs.2003.07.002

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ravichandran, C., Upadhyay, A. (2022). Processing of Pulses. In: Sharma, H.K., Kumar, N. (eds) Agro-Processing and Food Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-7289-7_11

Download citation

DOI: https://doi.org/10.1007/978-981-16-7289-7_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7288-0

Online ISBN: 978-981-16-7289-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)