Abstract

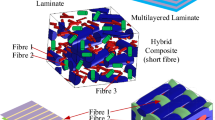

Polymer composites are those materials that form a synergistic mechanical advantage when reinforcement fillers are integrated into polymer. This advantage of the multiphase material possesses excellent wear and friction properties, hence found to be amenable with aerospace, automobile, and biomedical applications. The current article emphasizes the Tribological properties of various polymer composites concisely. However, alongside the Tribological advantage, there is a compromise in mechanical properties due to exposure of polymer composites to hazardous environments resulting in degradation and plasticization. With the advent of new manufacturing and processing techniques, by retaining the mechanical properties, the Tribological properties can be enhanced. In the current article, detailed attention to the microscopic and macroscopic Tribological aspects of polymer composites will be emphasized.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Aghababaei R, Warner DH, Molinari JF (2016) Critical length scale controls adhesive wear mechanisms. Nat Commun 7(1):1–8

Ammar IM, Huzaifah MRM, Sapuan SM, Ishak MR, Leman ZB (2018) Development of sugar palm fiber reinforced vinyl ester composites. In: Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites (pp 211–224). Woodhead Publishing

Ang KK, Ahmed KS (2013) An improved shear-lag model for carbon nanotube reinforced polymer composites. Compos B Eng 50:7–14

Bennewitz R, Dickinson JT (2008) Fundamental studies of nanometer-scale wear mechanisms. MRS Bull 33(12):1174–1180

Bhushan B, Israelachvili JN, Landman U (1995) Nanotribology: friction, wear and lubrication at the atomic scale. Nature 374(6523):607–616

Bhushan B, Kwak KJ (2007) Velocity dependence of nanoscale wear in atomic force microscopy. Appl Phys Lett 91(16):163113

Cirino M, Pipes RB, Friedrich K (1987) The abrasive wear behaviour of continuous fibre polymer composites. J Mater Sci 22(7):2481–2492

Erenkov OY, Igumnov PV, Nikishechkin VL (2010) Mechanical properties of polymer composites. Russ Eng Res 30(4):373–375

Friedrich K (2018) Polymer composites for tribological applications. Adv Ind Eng Polym Res 1(1):3–39

Friedrich K, Zhang Z, Schlarb AK (2005) Effects of various fillers on the sliding wear of polymer composites. Compos Sci Technol 65(15–16):2329–2343

Fukushima Y, Inagaki S (1987) J IncluPhen 5: 473–482. In: Fukushima Y, Okada A, Kawasumi M, Kurauchi T, Kamigaito O (eds) (1988) Clay Miner 23, pp 27–34

Giannelis EP (1996) Polymer layered silicate nanocomposites. Adv Mater 8(1):29–35

Gnecco E, Meyer E (eds) (2015) Fundamentals of friction and wear on the nanoscale. Springer, New York

Gotsmann B, Lantz MA (2008) Atomistic wear in a single asperity sliding contact. Phys Rev Lett 101(12):125501

Greenhalgh E (2009) Failure analysis and fractography of polymer composites. Elsevier

Greenwood JA, Williamson JP (1966) Contact of nominally flat surfaces. In: Proceedings of the royal society of London. Series A. Mathematical and physical sciences 295(1442):300–319

Halliday JS (1955) Surface examination by reflection electron microscopy. In: Proceedings of the Institution of mechanical engineers 169(1):777–787

Harsha AP, Tewari US, Venkatraman B (2003) Solid particle erosion behaviour of various polyaryletherketone composites. Wear 254(7–8):693–712

Jaśkiewicz R (2019) Comparison of composite laminates machining methods and its influence on process temperature and edge quality. Trans Aerosp Res 2019(4):46–54

Kundalwal SI, Ray MC, Meguid SA (2014) Shear lag model for regularly staggered short fuzzy fiber reinforced composite. J Appl Mech 81(9)

Lancaster JK (1968) Relationships between the wear of polymers and their mechanical properties. In: Proceedings of the Institution of Mechanical Engineers, Conference Proceedings (vol 183, No. 16, pp 98–106). Sage UK: London, England: SAGE Publications

Lanz RW, Melkote SN, Kotnis M (2001) Effect of process parameters and tool shape on the machinability of a particulate filled-polymer composite material for rapid tooling

Lednicky F, Michler GH (1990) Soft matrix fracture surface as a means to reveal the morphology of multi-phase polymer systems. J Mater Sci 25(10):4549–4554

Michler GH (2008) Electron microscopy of polymers. Springer Science & Business Media

Michler GH (1999) Micromechanics of polymers. J Macromol Sci Phys 38(5–6):787–802

Mo Y, Turner KT, Szlufarska I (2009) Friction laws at the nanoscale. Nature 457(7233):1116–1119

Myshkin NK, Petrokovets MI, Kovalev AV (2005) Tribology of polymers: adhesion, friction, wear, and mass-transfer. Tribol Int 38(11–12):910–921

Nuruzzaman DM, Rahaman ML, Chowdhury MA (2012) Friction coefficient and wear rate of polymer and composite materials at different sliding speeds. Int J Surf Sci Eng 6(3):231–245

Ojha S, Acharya SK, Gujjala R (2014) Characterization and wear behavior of carbon black filled polymer composites. Procedia Mater Sci 6:468–475

Omrani E, Menezes PL, Rohatgi PK (2016) State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng Sci Technol Int J 19(2):717–736

Prakash MO, Raghavendra G, Ojha S, Kumar D (2020) Investigation of tribological properties of biomass developed porous nano activated carbon composites. Wear 203523

Robertson RE (1976) Toughness and brittleness of plastics. Adv Chem Ser 154

Samal S (2020) Effect of shape and size of filler particle on the aggregation and sedimentation behavior of the polymer composite. Powder Technol

Smithies F (1952) Conduction of heat in solids. By HS Carslaw and JC Jaeger Pp. viii 386. 30s. 1947.(Oxford, at the Clarendon Press). The Mathematical Gazette 36(316):142–143

Srivastava VK, Jain PK, Kumar P, Pegoretti A, Bowen CR (2020) Smart manufacturing process of carbon-based low-dimensional structures and fiber-reinforced polymer composites for engineering applications. J Mater Eng Perform 29(7):4162–4186

Tewari US, Harsha AP, Häger AM, Friedrich K (2002) Solid particle erosion of unidirectional carbon fibre reinforced polyetheretherketone composites. Wear 252(11–12):992–1000

Tewari US, Harsha AP, Häger AM, Friedrich K (2003) Solid particle erosion of carbon fibre–and glass fibre–epoxy composites. Compos Sci Technol 63(3–4):549–557

Vajari DA, González C, Llorca J, Legarth BN (2014) A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites. Compos Sci Technol 97:46–54

Wang J (1999) Abrasive waterjet machining of polymer matrix composites–cutting performance, erosive process and predictive models. Int J Adv Manufact Technol 15(10):757–768

Zdero R, Guenther LE, Gascoyne TC (2017) Pin-on-disk wear testing of biomaterials used for total joint replacements. In: Experimental methods in orthopaedic biomechanics (pp 299–311). Academic Press

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Gara, D.K., Raghavendra, G., Ojha, S., Bandyopadhyay, S., Ismail, S., Rao, R.N. (2021). Scientific Insights on Tribological Aspects of Polymer Based Composites. In: Jena, H., Katiyar, J.K., Patnaik, A. (eds) Tribology of Polymer and Polymer Composites for Industry 4.0. Composites Science and Technology . Springer, Singapore. https://doi.org/10.1007/978-981-16-3903-6_2

Download citation

DOI: https://doi.org/10.1007/978-981-16-3903-6_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3902-9

Online ISBN: 978-981-16-3903-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)