Abstract

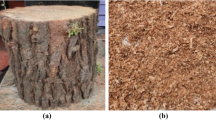

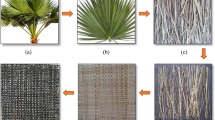

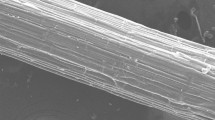

The latest advancements in composite materials have offered an additional advantage to engineers as far as quality and cost. Along these lines, these materials are being favored over the regular materials in pretty much every field of science and innovation. Henceforth, further improvement in the current age cannot be conceivable without thinking about the significance of composites. Among all developed composites, the demand for natural fiber-reinforced composites is growing day by day due to ongoing environmental concerns. In this context, an endeavor is accomplished to build a novel hybrid composite through the natural fibers extracted from the bark of the Terminalia bellirica tree. The hand layup method was adopted for the preparation of the composite samples. To strengthen the mechanical properties of the material, carbon fibers, in varying weight percentages, were also dispersed in the matrix phase. The prepared samples were cut as per the ASTM standards for examining the tensile, flexural, and hardness attributes of the material. The results reveal that the varying percentage of T. bellirica + carbon fibers heavily affect the mechanical attributes of the developed composites. With this varying dispersion, the tensile strength of the composites samples increases whereas the flexural strength and hardness decrease.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Thakur, A., Purohit, R., Rana, R. S., & Bandhu, D. (2018). Characterization and evaluation of mechanical behavior of epoxy-CNT-bamboo matrix hybrid composites. Materials Today Proceedings, 5, 3971–3980. https://doi.org/10.1016/j.matpr.2017.11.655

Bandhu, D., Mohan, M. M., Praveen, G., Yadav, K., Reddy, K. J., & Shavali, G. S. (2016). Mechanical properties of Makhana (Euryale Ferox Salisbury) reinforced composite. IJSRD—International Journal of Science Research Development, 4, 2321–2613.

Hull, D., & Clyne, T. W. (1996). An introduction to composite materials. Cambridge University Press. https://doi.org/10.1017/cbo9781139170130

Ngo, T.-D. (2020) Introduction to composite materials. In Fiber Composites. IntechOpen. https://doi.org/10.5772/intechopen.91285.

Komanduri, R. (1997). Machining of fiber-reinforced composites. https://www.tandfonline.com/doi/abs/10.1080/10940349708945641.

Kumar, D., & Singh, K. K. (2015). An approach towards damage free machining of CFRP and GFRP composite material: A review. Advanced Composite Materials, 24, 49–63. https://doi.org/10.1080/09243046.2014.928966

Kuruc, M. (2020). Machining of composite materials by ultrasonic assistance. Advanced Science Technology Research of Journal, 14, 140–144. https://doi.org/10.12913/22998624/118943.

Ablyaz, T. R., Muratov, K. R., Shlykov, E. S., Shipunov, G. S., & Shakirzyanov, T. V. (2019). Electric-discharge machining of polymer composites. Russian Engineering Research, 39, 898–900. https://doi.org/10.3103/S1068798X19100058

Mohamed, S. B., Rashid, R. A., Muhamad, M., & Ismail, J. (2019). Composite materials and types of machining. In SpringerBriefs in applied sciences and technology (pp. 1–14). Springer Verlag. https://doi.org/10.1007/978-981-13-1804-7_1.

Bandhu, D., Thakur, A., Purohit, R., Verma, R. K., & Abhishek, K. (2018). Characterization & evaluation of Al7075 MMCs reinforced with ceramic particulates and influence of age hardening on their tensile behavior. Journal of Mechanical Science and Technology, 32, 3123–3128. https://doi.org/10.1007/s12206-018-0615-9

Naga Phani Sastry, M., Devaki Devi, K., & Bandhu, D. (2016). Characterization of Aegle Marmelos fiber reinforced composite. International Journal of Engineering Research, 5, 345–349. https://doi.org/10.17950/ijer/v5i2/009.

Shavali, G. S., Venugopal Goud, E., Praveen, G., Yadav, K., & Bandhu, D. (2016). Tensile and flexural characterization of Nomex and E-glass fibre reinforced epoxy composites. IJSRD—International Journal of Science Research Development, 4, 2321–2613.

Tripathi, D. R., Vachhani, K. H., Kumari, S., Dinbandhu, & Abhishek, K. (2020). Experimental investigation on material removal rate during abrasive water jet machining of GFRP composites. Materials Today Proceedings, 26, 1389–1392. https://doi.org/10.1016/j.matpr.2020.02.280.

Shesan, O. J., Stephen, A. C., Chioma, A. G., Neerish, R., & Rotimi, S. E. (2019). Improving the mechanical properties of natural fiber composites for structural and biomedical applications. In Renewable and sustainable composites. IntechOpen. https://doi.org/10.5772/intechopen.85252.

Jeyapragash, R., Srinivasan, V., & Sathiyamurthy, S. (2020). Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Materials Today: Proceedings, 1223–1227. https://doi.org/10.1016/j.matpr.2019.12.146.

Vinayagamoorthy, R. (2019). Trends and challenges on the development of hybridized natural fiber composites. Journal of Natural Fibers, 1–18. https://doi.org/10.1080/15440478.2019.1598916.

Ashok, K. G., & Damodaran, A. (2020). Mechanical and morphological properties of luffa/carbon fiber reinforced hybrid composites. Materials Today Proceedings. https://doi.org/10.1016/j.matpr.2020.05.716

Bakshi, P., Pappu, A., Patidar, R., Gupta, M. K., & Thakur, V. K. (2020). Transforming marble waste into high-performance, water-resistant, and thermally insulative hybrid polymer composites for environmental sustainability. Polymers (Basel), 12, 1781. https://doi.org/10.3390/polym12081781.

Oliveira, P. R., Ribeiro Filho, S. L. M., Panzera, T. H., Christoforo, A. L., Durão, L. M. P., & Scarpa, F. (2020). Hybrid polymer composites made of sugarcane bagasse fibres and disposed rubber particles. Polymers and Polymer Composites, 096739112094345. https://doi.org/10.1177/0967391120943459.

Prabhuram, T., Elilraja, D., Prathap Singh, S., & Durairaj, I. (2021) Investigation of mechanical and chemical properties of the coir fiber and wood powder reinforced hybrid polymer composite. In Lecture Notes in Mechanical Engineering, pp. 285–292. Springer. https://doi.org/10.1007/978-981-15-4745-4_26.

Akash, S. R., Patil, V., & Girisha, K. G. (2021) An experimental study on hemp/sisal fiber embedded hybrid polymer composites. In Lecture Notes in Mechanical Engineering. pp. 293–301. Springer. https://doi.org/10.1007/978-981-15-4745-4_27.

Somaiah Chowdary, M., Raghavendra, G., Niranjan Kumar, M. S. R., Ojha, S., & Om Prakash, M. (2020) A review on the degradation of properties under the influence of liquid medium of hybrid polymer composites. SN Application Science, 2, 1708. https://doi.org/10.1007/s42452-020-03502-7.

Sinha, A. K., Narang, H. K., Bhattacharya, S. (2020). Mechanical properties of hybrid polymer composites: A review. https://doi.org/10.1007/s40430-020-02517-w.

Priya, I. I. M., & Vinayagam, B. (2018). Enhancement of bi-axial glass fibre reinforced polymer composite with graphene platelet nanopowder modifies epoxy resin. Advances in Mechanical Engineering, 10, 168781401879326. https://doi.org/10.1177/1687814018793261

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Dinbandhu, Abhishek, K., Thakur, A., Nagaphani Sastry, M., Devaki Devi, K., Nishant, A. (2021). A Study on Mechanical Attributes of Epoxy-Carbon Fiber-Terminalia bellirica Embedded Hybrid Composites. In: Agrawal, R., Jain, J.K., Yadav, V.S., Manupati, V.K., Varela, L. (eds) Recent Advances in Smart Manufacturing and Materials. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-3033-0_15

Download citation

DOI: https://doi.org/10.1007/978-981-16-3033-0_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3032-3

Online ISBN: 978-981-16-3033-0

eBook Packages: EngineeringEngineering (R0)