Abstract

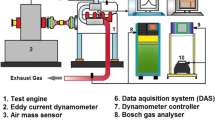

The demand for fossil fuel and its price is rising every year, and hence, the dominant fuel source, i.e., petroleum-based fuel, is depleting at a faster rate leading to harmful pollution. The usage of vegetable oil eradicates these two drawbacks as fuel. But the main disadvantage of vegetable oil is low performance and combustion characteristics due to its higher value of viscosity. The main objective of this research is to reduce the vegetable oil viscosity by the transesterification process and to blend with diesel oil and to study its fuel properties, performance, combustion and emissions characteristics in detail. Here, Jatropha oil is experimented as fuel due to its availability in plenty. The Jatropha biofuel is blended with diesel in various proportions (J20, J40, J60, J80 & J100) by the transesterification process. An experimental study was conducted with fuel samples in an unmodified single-cylinder compression ignition engine. From the experimental information, it was observed that brake thermal efficiency decreased while brake specific fuel consumption increased as the proportion of Jatropha increased in biodiesel. However, biodiesel blend J20 had a higher brake thermal efficiency of 31.1% at 80% load conditions, and it was closer to that of diesel, which is 32.5%. Jatropha blend had a closer combustion characteristic such as heat release rate and rate of pressure rise to diesel oil. Most of the primary exhaust pollutants, such as carbon monoxide, carbon dioxide and hydrocarbons, were comparatively lower for Jatropha oil, but an increase in NOx and smoke opacity was observed. However, blend J20 had value comparable with diesel. The outcome of the experimental investigation on performance, combustion and emission on Jatropha biodiesel indicated that J20 could be the best alternative fuel as it gave better efficiency and emissions similar to those of diesel, then it could be directly used in CI engine without any modification.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- ASTM:

-

American Society for Testing Materials

- CI:

-

Compression ignition

- CO:

-

Carbon monoxide

- HC:

-

Hydrocarbon

- CO2:

-

Carbon dioxide

- NOx:

-

Oxides of nitrogen

- HRR:

-

Heat release rate

- J20:

-

20% transesterified Jatropha oil and 80% diesel in volume

- J40:

-

40% transesterified Jatropha oil and 60% diesel in volume

- J60:

-

60% transesterified Jatropha oil and 40% diesel in volume

- J80:

-

80% transesterified Jatropha oil and 20% diesel in volume

- J100:

-

100% volume of transesterified Jatropha oil in volume

References

Rehman, A., Phalke, D. R., & Pandey, R. (2011). Alternative fuel for gas turbine: Esterified jatropha oil–diesel blend. Renewable Energy, 36(10), 2635–2640.

Balasubramanian, D., Kamaraj, S., & Krishnamoorthy, R. (2020). Synthesis of biodiesel from waste cooking oil by alkali doped calcinated waste egg shell powder catalyst and optimization of process parameters to improve biodiesel conversion (No. 2020-01-0341). SAE Technical Paper.

Kaisan, M. U., Abubakar, S., Ashok, B., Balasubramanian, D., Narayan, S., Grujic, I., & Stojanovic, N. (2018). Comparative analyses of biodiesel produced from jatropha and neem seed oil using a gas chromatography–mass spectroscopy technique. Biofuels, 1–12.

Mat, S. C., Idroas, M. Y., Hamid, M. F., & Zainal, Z. A. (2018). Performance and emissions of straight vegetable oils and its blends as a fuel in a diesel engine: A review. Renewable and Sustainable Energy Reviews, 82, 808–823.

EL-Seesy, A. I., He, Z., Hassan, H., & Balasubramanian, D. (2020). Improvement of combustion and emission characteristics of a diesel engine working with diesel/jojoba oil blends and butanol additive. Fuel, 279, 118433.

Gautam, A., & Agarwal, A. K. (2013). Experimental investigations of comparative performance, emission and combustion characteristics of a cottonseed biodiesel-fueled four-stroke locomotive diesel engine. International Journal of Engine Research, 14(4), 354–372.

Ali, M. H., Mashud, M., Rubel, M. R., & Ahmad, R. H. (2013). Biodiesel from neem oil as an alternative fuel for diesel engines. Procedia Engineering, 56, 625–630.

da Silva, M. A. V., Ferreira, B. L. G., da Costa Marques, L. G., Murta, A. L. S., & de Freitas, M. A. V. (2017). Comparative study of NOx emissions of biodiesel-diesel blends from soybean, palm, and waste frying oils using methyl and ethyl transesterification routes. Fuel, 194, 144–156.

Leung, D. Y., Wu, X., & Leung, M. K. H. (2010). A review on biodiesel production using catalyzed transesterification. Applied Energy, 87(4), 1083–1095.

Sahoo, P. K., Das, L. M., Babu, M. K. G., Arora, P., Singh, V. P., Kumar, N. R., et al. (2009). Comparative evaluation of performance and emission characteristics of Jatropha, karanja, and polanga based biodiesel as fuel in a tractor engine. Fuel, 88(9), 1698–1707.

Gog, A., Roman, M., Toşa, M., Paizs, C., & Irimie, F. D. (2012). Biodiesel production using enzymatic transesterification–current state and perspectives. Renewable Energy, 39(1), 10–16.

Lee, A. F., Bennett, J. A., Manayil, J. C., & Wilson, K. (2014). Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chemical Society Reviews, 43(22), 7887–7916.

Kouzu, M., & Hidaka, J. S. (2012). Transesterification of vegetable oil into biodiesel catalyzed by CaO: A review. Fuel, 93, 1–12.

Ramalingam, K., Balasubramanian, D., Chellakumar, P. J. T. J. S., Padmanaban, J., Murugesan, P., & Xuan, T. (2020). An assessment on production and engine characterization of a novel environment-friendly fuel. Fuel, 279,.

Lingesan, S., Annamalai, K., Parthasarathy, M., Ramalingam, K. M., Dhinesh, B., & Lalvani, J. I. J. (2018). Production of Garcinia gummi-gutta methyl ester (GGME) as a potential alternative feedstock for existing unmodified DI diesel engine: Combustion, performance, and emission characteristics. Journal of Testing and Evaluation, 46(6), 2661–2678.

Khalid, A., Tajuddin, A. S. A., Jaat, N., Manshoor, B., Zaman, I., Hadi, S. A. A., et al. (2017). Performance and emissions of a diesel engine fuelled with preheated biodiesel fuel derived from crude palm, Jatropha, and waste cooking oils. International Journal of Automotive and Mechanical Engineering, 14, 4273–4284.

Chauhan, B. S., Kumar, N., Du Jun, Y., & Lee, K. B. (2010). Performance and emission study of preheated Jatropha oil on a medium-capacity diesel engine. Energy, 35(6), 2484–2492.

Hazar, H., & Aydin, H. (2010). Performance and emission evaluation of a CI engine fueled with preheated raw rapeseed oil (RRO)–diesel blends. Applied Energy, 87(3), 786–790.

Jeyakumar, N., Narayanasamy, B., Balasubramanian, D., & Viswanathan, K. (2020). Characterization and effect of Moringa Oleifera Lam. antioxidant additive on the storage stability of Jatropha biodiesel. Fuel, 281, 118614.

Pradhan, P., Raheman, H., & Padhee, D. (2014). Combustion and performance of a diesel engine with preheated Jatropha curcas oil using waste heat from the exhaust gas. Fuel, 115, 527–533.

Anand, B. P., Saravanan, C. G., & Srinivasan, C. A. (2010). Performance and exhaust emission of turpentine oil powered direct injection diesel engine. Renewable Energy, 35(6), 1179–1184.

Nabi, M. N., Akhter, M. S., & Shahadat, M. M. Z. (2006). Improvement of engine emissions with conventional diesel fuel and diesel–biodiesel blends. Bioresource Technology, 97(3), 372–378.

Tarabet, L., Loubar, K., Lounici, M. S., Khiari, K., Belmrabet, T., & Tazerout, M. (2014). Experimental investigation of DI diesel engine operating with eucalyptus biodiesel/natural gas under dual fuel mode. Fuel, 133, 129–138.

Gogoi, T. K., & Baruah, D. C. (2011). The use of Korach seed oil methyl ester blends as fuel in a diesel engine. Applied Energy, 88(8), 2713–2725.

Haiter, L. A., Ravi, R., Arumugham, S., & Thyagarajan, K. (2012). Performance, emission, and combustion evaluation of diesel engines using methyl esters of Mahua oil. International Journal of Environmental Sciences, 3(1), 639–649.

Agarwal, A. K., & Dhar, A. (2013). Experimental investigations of performance, emission, and combustion characteristics of Karanja oil blends fuelled the DICI engine. Renewable Energy, 52, 283–291.

Nithyananda, B. S., Anand, A., & Prakash, G. V. N. (2013). Experimental investigation of neem and mixed Pongamia-coconut methyl esters as biodiesel on CI engine. International Journal of Mechanical Engineering & Technology, 4, 232–242.

Sanjid, A., Masjuki, H. H., Kalam, M. A., Abedin, M. J., & Rahman, S. A. (2014). Experimental investigation of mustard biodiesel blend properties, performance, exhaust emission, and noise in an unmodified diesel engine. APCBEE Procedia, 10, 149–153.

Nalgundwar, A., Paul, B., & Sharma, S. K. (2016). Comparison of performance and emissions characteristics of DI CI engine fueled with dual biodiesel blends of palm and Jatropha. Fuel, 173, 172–179.

Kakati, J., & Gogoi, T. K. (2016). Biodiesel production from Kutkura (Meyna Spinosa Roxb. Ex.) fruit seed oil: Its characterization and engine performance evaluation with 10 and 20% blends. Energy Conversion and Management, 121, 152–161.

Datta, A., & Mandal, B. K. (2014). Use of Jatropha biodiesel as a future sustainable fuel. Energy Technology & Policy, 1(1), 8–14.

Buyukkaya, E. (2010). Effects of biodiesel on a DI diesel engine performance, emission, and combustion characteristics. Fuel, 89(10), 3099–3105.

Silitonga, A. S., Ong, H. C., Mahlia, T. M. I., Masjuki, H. H., & Chong, W. T. (2014). Biodiesel conversion from high FFA crude jatropha curcas, Calophyllum inophyllum, and Ceiba pentandra oil. Energy Procedia, 61, 480–483.

Henning, R. K. (1994). Fighting desertification by integrated utilisation of the Jatropha plant. www.Jatropha.org.

Xiao, J., Zhang, H., & Niu, L. (2015). Effect of detoxification on conformational and functional properties of Jatropha curcas proteins. International Journal of Food Properties, 18(7), 1524–1534.

Rani, C., Kajla, S., Pal, M., Poonia, A. K., & Kharb, P. (2013). Jatropha curcas: A potential source for biofuel production. Renewable Energy Sources and Their Applications, 155.

Silitonga, A. S., Atabani, A. E., Mahlia, T. M. I., Masjuki, H. H., Badruddin, I. A., & Mekhilef, S. (2011). A review of the prospect of Jatropha curcas for biodiesel in Indonesia. Renewable and Sustainable Energy Reviews, 15(8), 3733–3756.

Kim, H., & Choi, B. (2010). The effect of biodiesel and bioethanol blended diesel fuel on nanoparticles and exhaust emissions from the CRDI diesel engine. Renewable Energy, 35(1), 157–163.

Padhi, S. K. (2010). Preparation and characterization of biodiesel from non-edible oils (Doctoral dissertation).

Ahmed, W., Nazar, M. F., Ali, S. D., Rana, U. A., & Khan, S. U. D. (2015). Detailed investigation of optimized alkali catalyzed transesterification of Jatropha oil for biodiesel production. Journal of Energy Chemistry, 24(3), 331–336.

Kawakami, K., Oda, Y., & Takahashi, R. (2011). Application of a Burkholderia cepacialipase-immobilized silica monolith to batch and continuous biodiesel production with a stoichiometric mixture of methanol and crude Jatropha oil. Biotechnology for Biofuels, 4(1), 42.

Karthickeyan, V., Thiyagarajan, S., Ashok, B., Geo, V. E., & Azad, A. K. (2020). Experimental investigation of pomegranate oil methyl ester in ceramic coated engine at different operating condition in direct injection diesel engine with energy and exergy analysis. Energy Conversion and Management, 205,.

Özener, O., Yüksek, L., Ergenç, A. T., & Özkan, M. (2014). Effects of soybean biodiesel on a DI diesel engine performance, emission, and combustion characteristics. Fuel, 115, 875–883.

Kumar, P., Sharma, M. P., & Dwivedi, G. (2014). Impact of biodiesel on combustion, performance, and exhaust emissions of diesel engines. Journal of Integrated Science and Technology, 2(2), 57–63.

Elango, T., & Senthilkumar, T. (2011). Combustion and emission characteristics of a diesel engine fuelled with jatropha and diesel oil blends. Thermal Science, 15(4), 1205–1214.

Jeevahan, J., Mageshwaran, G., Joseph, G. B., Raj, R. D., & Kannan, R. T. (2017). Various strategies for reducing Nox emissions of biodiesel fuel used in conventional diesel engines: A review. Chemical Engineering Communications, 204(10), 1202–1223.

Acknowledgements

The authors would like to convey their heartfelt thanks to Dr. S. Saravanan, Principal, CK College of Engineering and Technology, Cuddalore, for encouraging this research work and to the authorities of Mepco Schlenk Engineering College, Sivakasi, for their support.

Declaration of Competing Interest

The authors announce that they have no recognized competing financial interests or personal relationships that could have seemed to influence the work described in this article.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Balasubramanian, D., Rajarajan, A., Krishnamoorthy, R., Quoc, T.D. (2021). Experimental Investigation of Unmodified Diesel Engine on Performance, Combustion and Emission with Various Proportions of Jatropha Biofuel in Diesel. In: Singh, A.P., Kumar, D., Agarwal, A.K. (eds) Alternative Fuels and Advanced Combustion Techniques as Sustainable Solutions for Internal Combustion Engines. Energy, Environment, and Sustainability. Springer, Singapore. https://doi.org/10.1007/978-981-16-1513-9_7

Download citation

DOI: https://doi.org/10.1007/978-981-16-1513-9_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1512-2

Online ISBN: 978-981-16-1513-9

eBook Packages: EnergyEnergy (R0)