Abstract

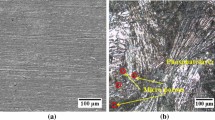

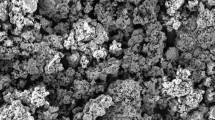

Molybdenum disulphide (MoS2) is widely used in various applications because of its lubricating properties. However, its performance needs to further improve. In the present work Molybdenum disulphide (MoS2) based composite coating with addition of TiO2 (having different particle size and weight% addition) were developed and coated on AISI52100 steel substrate. The substrate specimens were pre-treated using phosphating to improve the porosity which helps to enhance the bond strength between the coating and steel substrate. A tribological study of this developed composite coating was carried out at different contact pressures and sliding speeds using the pin-on-disc test rig. It was observed that particle size of TiO2 and its different wt% significantly affects the tribological properties of the developed composite coating. In case of all considered operating conditions with developed samples of composite MoS2-TiO2 coating, the sample C (63.3 nm particle size with 15 wt% addition) of TiO2 depicts about 31% lower coefficient of friction and 39% lower wear rate compared to pure MoS2 coating.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Arslan E, Bulbul F, Efeoglu I (2004) The structural and tribological properties of MoS2-Ti composite solid lubricants. Tribol Trans 47(2):218–226

ASTM AS. G99 (2010) Standard test method for wear testing with a pin-on-disk apparatus, pp 1–5

Bulbul F, Efeoglu I (2010) MoS2-Ti composite films having (002) orientation and low Ti content. Crystallogr Rep 55(7):1177–1182

Chen JM, Jia JH (2001) Investigation of the tribological behavior of an aluminum alloy with embedded materials. Mater Sci Eng 302(2):222–226

Ding XZ, Zeng XT, He XY, Chen Z (2010) Tribological properties of Cr-and Ti-doped MoS2 composite coatings under different humidity atmosphere. Surf Coat Technol 205(1):224–231

Duszczyk J, Siuzdak K, Klimczuk T, Strychalska-Nowak J, Zaleska-Medynska A (2018) Manganese phosphatizing coatings: the effects of preparation conditions on surface properties. Materials 11(12):1–22

Erdemir A (2000) Solid lubricants and self-lubricating films. In: Bhushan B (ed) Modern tribology handbook. CRC Press, US, pp 4–39

Essa FA, Zhang Q, Huang X, Ali MKA, Elagouz A, Abdelkareem MA (2017) Effects of ZnO and MoS2 solid lubricants on mechanical and tribological properties of M50-steel-based composites at high temperatures: experimental and simulation study. Tribol Lett 65(3):1–29

Fridrici V, Fouvry S, Kapsa P, Perruchaut P (2003) Impact of contact size and geometry on the lifetime of a solid lubricant. Wear 255(7–12):875–882

Gadow R, Scherer D (2002) Composite coatings with dry lubrication ability on light metal substrates. Surf Coat Technol 151:471–477

Hernandez-Perez I, Maubert AM, Rendon L, Santiago P, Herrera-Hernandez H, Diaz-Barriga Arceo L, Garibay Febles V, Palacios Gonzalez E, Gonzalez-Reyes L (2012) Ultrasonic synthesis: structural, optical and electrical correlation of TiO2 nanoparticles. Int J Electrochem Sci 7:8832–8847

Hiraoka N (2001) Wear life mechanism of journal bearings with bonded MoS2 film lubricants in air and vacuum. Wear 249(10–11):1014–1020

Kubart T, Polcar T, Kopecky L, Novak R, Novakova D (2005) Temperature dependence of tribological properties of MoS2 and MoSe2 coatings. Surf Coat Technol 193(1–3):230–233

Luo J, Zhu MH, Wang YD, Zheng JF, Mo JL (2011) Study on rotational fretting wear of bonded MoS2 solid lubricant coating prepared on medium carbon steel. Tribol Int 44(11):1565–1570

Menezes PL, Nosonovsky M, Ingole SP, Kailas SV, Lovell MR (eds) (2013) Tribology for scientists and engineers. Springer, New York

Pokorny P, Tej P, Szelag P (2016) Discussion about magnesium phosphating. Metalurgija 55(3):507–510

Rajagopal C, Vasu KI (2000) Properties of phosphate coatings and influencing factors. In: Conversion coatings: a reference for phosphating, chromating, and anodizing processes. Tata McGraw-Hill, New York, pp 62–70

Ramamoorthy R, Venkatesan T, Rajendran R (2017) Solid lubricant assisted machining—an environmental friendly clean technology to improve the surface quality. SAE Tech Pap 28(1):1–4

Sankara Narayanan TSN (2005) Surface pretretament by phosphate conversion coatings—a review. Rev Adv Mater Sci 9:130–177

Shang K, Zheng S, Ren S, Pu J, He D, Liu S (2018) Improving the tribological and corrosive properties of MoS2-based coatings by dual-doping and multilayer construction. Appl Surf Sci 437:233–244

Shankara A, Menezes PL, Simha KRY, Kailas SV (2008) Study of solid lubrication with MoS2 coating in the presence of additives using reciprocating ball-on-flat scratch tester. Sadhana 33(3):207–220

Sharma SM, Anand A (2016) Solid lubrication in iron based materials—a review. Tribol Ind 38(3):318–331

Shen MX, Cai ZB, Peng JF, Peng XD, Zhu MH (2017) Antiwear properties of bonded MoS2 solid lubricant coating under dual-rotary fretting conditions. Tribol Trans 60(2):217–225

Vadiraj A, Kamaraj M, Sreenivasan VS (2012) Effect of solid lubricants on friction and wear behaviour of alloyed gray cast iron. Sadhana 37(5):569–577

Xu J, Zhu MH, Zhou ZR, Kapsa P, Vincent L (2003) An investigation on fretting wear life of bonded MoS2 solid lubricant coatings in complex conditions. Wear 255(1–6):253–258

Xu J, Zhou ZR, Zhang CH, Zhu MH, Luo JB (2007) An investigation of fretting wear behaviours of bonded solid lubricant coatings. J Mater Process Technol 182(1–3):146–151

Ye Y, Chen J, Zhou H (2009) An investigation of friction and wear performances of bonded molybdenum disulfide solid film lubricants in fretting conditions. Wear 266(7–8):859–864

Zhu X, Lauwerens W, Cosemans P, Van Stappen M, Celis JP, Stals LM, He J (2003) Different tribological behavior of MoS2 coatings under fretting and pin-on-disk conditions. Surf Coat Technol 163:422–428

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Borgaonkar, A.V., Syed, I., Sonawane, S.H. (2021). Effects of Lubrication on Tribological Properties of Composite MoS2-TiO2 Coating Material. In: Hameed Sultan, M.T., Mohd Jamir, M.R., Abdul Majid, M.S., Azmi, A.I., Saba, N. (eds) Tribological Applications of Composite Materials. Composites Science and Technology . Springer, Singapore. https://doi.org/10.1007/978-981-15-9635-3_10

Download citation

DOI: https://doi.org/10.1007/978-981-15-9635-3_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9634-6

Online ISBN: 978-981-15-9635-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)