Abstract

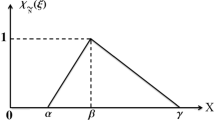

In reality, there are different types of supply-chain system for production. One such type may be that a producer purchases raw materials from several vendors and the finished products are sold to a retailer. The retailer may plan to procure in large quantity to avail the price discount, transportation advantage, etc., and adopt for warehouse facilities system-one warehouse at the market place from where sale is conducted and the other (if necessary) at a distance away from the market place from which the units are transported to the market warehouse (MW) continuously to keep MW full. This motivated us to take up the following three supply-chain production inventory models. In the first model, the above mentioned type two warehouse supply chain model (SCM) is considered with imprecise stock dependent demand and in this model the objective goal is assumed to be fuzzy. There are budget and space constraints which are also in fuzzy nature. The fuzziness are defuzzified following possibility, necessity and credibility measures. In the second model (i) nature of collection of raw-material is different; (ii) demand is increasing with time in a decreasing rate, (iii) selling price of the partial backlogging units depends on the waiting time of the customers. The model is formulated with defective production system and learning effect which is fuzzy in nature. Learning effect i.e., experience is introduced in reducing the defective rate in production. In last model, an integrated production-inventory model is presented for a supplier, manufacturer, and retailer supply chain under conditionally permissible delay in payments in uncertain environments. The supplier produces the item at a certain rate, which is a decision variable, and purchases the item to the manufacturer. The manufacturer has also purchased and produced the item in a finite rate. The manufacturer sells the product to the retailer and also gives the delay in payment to the retailer. The retailer purchases the item from the manufacture to sell it to the customers. Ideal costs of supplier, manufacturer, and retailer have been taken into account. The SCMs have been developed and solved analytically fuzzy environments, and finally, corresponding individual profits are calculated numerically and graphically.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Agarwal, V., Chao, X., Seshadri, S.: Dynamic balancing of inventory in supply chains. Eur. J. Oper. Res. 159, 296–317 (2004)

Bhunia, A.K., Maiti, M.: A two warehouses inventory model for deteriorating items with a linear trend in demand and shortages. J. Oper. Res. Soc. 49, 287–292 (1997)

Cachon, G.P., Zipkin, P.H.: Competitive and cooperative inventory policies in a two-stage supply chain. Manage. Sci. 45, 936–953 (1999)

Chen, C., Yuan, T., Lee, W.: Multi-criteria fuzzy optimization for locating warehouses and distribution centers in a supply chain network. J. Chin. Inst. Chem. Eng. 38, 393–407 (2007)

Chu, S.J.: Interactive group decision-making using a fuzzy linguistic approach for evaluating the flexibility in a supply chain. Eur. J. Oper. Res. 213, 279–289 (2011)

Cohen, M.A., Baghanan, M.P.: The stabilizing effect of inventory in supply chains. Oper. Res. 46, S72–S83 (1998)

Das, B., Maity, K., Maiti, M.: A Two Warehouse Supply-Chain Model Under Possibility/Necessity/Credibility Measures. Math.Comput. Model. 46, 398–409 (2007)

Dubois, D., Prade, H.: Ranking Fuzzy numbers in the setting of Possibility Theory. Inf. Sci. 30, 183–224 (1983)

Gabriel, G.A., Ragsdell, K.M.: The Generalized Reduced Gradient Method. AMSE J. Eng. Ind. 99, 384–400 (1977)

Goldberg, D.E.: Genetic Algorithms: Search, Optimization and Machine Learning. Addison Wesley, Massachusetts (1989)

Goyal, S.K.: Economic order quantity under conditions of permissible delay in payments. J. Oper. Res. Soc. 36, 35–38 (1985)

Grzegorzewski, P.: Nearest interval approximation of a fuzzy number. Fuzzy Sets Syst. 130, 321–330 (2002)

Kabak, O., Ulengin, F.: Possibilistic linear-programming approach for supply chain networking decisions. Eur. J. Oper. Res. 209, 253–264 (2011)

Karabakal, N., Gunal, A., Ritchie, W.: Supply-chain analysis at volkswagen of America. J. Interfaces-Supply-Chain Manage. 30(4), 46–55 (2000)

Khanra, S., Ghosh, S.K., Chaudhuri, K.S.: An EOQ model for a deteriorating item with time dependent quadratic demand under permissible delay in payment. Appl. Math. Comput. 218, 1–9 (2011)

Kristianto, Y., Helo, P., Jiao, J., Sandhu, M.: Adaptive fuzzy vendor managed inventory control for mitigating the Bullwhip effect in supply chains. Eur. J. Oper. Res. 216, 346–355 (2012)

Liu, B., Iwamura, K.B.: Chance constraint Programming with fuzzy parameters. Fuzzy Sets Syst. 94, 227–237 (1998)

Liu, B., Liu, Y.K.: Expected value of fuzzy variable and fuzzy expected value models. IEEE Trans. Fuzzy Syst. 10, 445–450 (2002)

Maihami, R., Abadi, I.N.K.: Joint control of inventory and its pricing for non-instantaneously deteriorating items under permissible delay in payments and partial backlogging mathematical and computer modelling. 55, 1722–1733 (2012)

Maiti, M.K., Maiti, M.: Fuzzy inventory model with two warehouses under possibility constraints. Fuzzy Sets Syst. 157, 52–73 (2006)

Maity, K., Maiti, M.: Numerical approach of multi-objective optimal control problem in imprecise environment. Fuzzy Optim. Decis. Making 4, 313–330 (2005)

Maity, K., Maiti, M.: Possibility and necessity constraints and their defuzzification– a multi-item production -inventory scenario via optimal control theory. Eur. J. Oper. Res. 177, 882–896 (2007)

Maity, K.: Possibility and necessity representations of fuzzy inequality and its application to two warehouse production-inventory problem. Appl. Math. Model. 35, 1252–1263 (2011)

Monthatipkul, C., Yenradee, P.: Inventory/distribution control system in a one-warehouse/multi-retailer supply chain. Int. J. Prod. Econ. 114, 119–133 (2008)

Moore, R.E.: Method and Application of Interval Analysis. SIAM, Philadelphia (1979)

Oliver, R.K., Webber, M.D.: Supply-chain management: logistics catches up with strategy (reprint from Outlook 1982). In: Christopher M. (ed.). Logistics-The Strategic Issue, pp. 62–75. London (1982)

Pakkala, T.P.M., Achary, K.K.: Discrete time inventory model for deteriorating items with two warehouses. Opsearch 29, 90–103 (1992)

Paksoy, T., Pehlivan, N.Y.: A fuzzy linear programming model for the optimization of multi-stage supply chain networks with triangular and trapezoidal membership functions. J. Franklin Inst. 349, 93–109 (2012)

Peidro, D., Mula, J., Jimenez, M., Botella, M.M.: A fuzzy linear programming based approach for tactical supply chain planning in an uncertainty environment. Eur. J. Oper. Res. 205, 65–80 (2010)

Rau, H., Wu, M.Y., Wee, H.M.: Deteriorating item inventory model with shortage due to supplier in an integrated supply chain. Int. J. Syst. Sci. 35, 293–303 (2004)

Viswanathan, S., Piplani, R.: Coordinating supply chain inventories through common replenishment epochs. Eur. J. Oper. Res. 129, 277–286 (2001)

Wang, X., Chan, H.K., Yee, R.W.Y., Rainey, I.D.: A two-stage fuzzy-AHP model for risk assessment of implementing green initiatives in the fashion supply chain. Int. J. Prod. Econ. 135, 595–606 (2012)

Wang, J., Shu, Y.F.: Fuzzy decision modelling for supply chain management. Fuzzy Sets Syst. 150, 107–127 (2005)

Zhou, Y.W., Lau, H.S., Yang, S.L.: A new variable production scheduling strategy for deteriorating items with time-varying demand and partial lost sale. Comput. Oper. Res. 30, 1753–1776 (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Maity, K. (2014). A Supply-Chain Production Inventory Model with Warehouse Facilities Under Fuzzy Environment. In: Kahraman, C., Öztayşi, B. (eds) Supply Chain Management Under Fuzziness. Studies in Fuzziness and Soft Computing, vol 313. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-53939-8_22

Download citation

DOI: https://doi.org/10.1007/978-3-642-53939-8_22

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-53938-1

Online ISBN: 978-3-642-53939-8

eBook Packages: EngineeringEngineering (R0)