Abstract

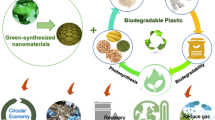

Recent interest in environmentally friendly bio-based polymers coupled with an increased food safety awareness has resulted in various packaging technology advances, including the incorporation of different kinds of nanofillers into biodegradable biopolymers to improve their overall properties for improving shelf life and preventing microbial growth. Among the different nanofillers that have recently emerged, graphene’s invention has catalyzed a multitude of novel material applications in different fields. Graphene has functionalized different biopolymers and has improved their mechanical, thermal, electrical, as well as, gas, and water vapor barrier properties, for potentially replacing petrochemical-based packaging materials that pose a great threat to the environment. The objective of this chapter is to provide comprehensive understanding of the different types of nanoreinforcement that are available for biodegradable packaging application, especially focusing on graphene oxide (GO), a graphene derivative nanofiller that is being extensively studied for packaging reinforcement. This chapter aims to draw a clear picture of synthesis and chemistry of bonding between graphene derivatives and biodegradable biopolymers suitable for packaging applications, like starch, cellulose, poly(lactic acid), and others. The methodology behind the chemical and physical changes during synthesis will be discussed, based on different spectroscopic characterization techniques, and the influence of chemical changes on resulting properties will also be highlighted. This chapter will also briefly go over other nanomaterials like clay, cellulose nanofibers, starch nanocrystals, and their usage in different biopolymers for packaging application. This will help to explain the synergy resulting from addition of nanomaterials, the use of different characterization techniques as well as the improvement in different properties.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Affdl JCH, Kardos JL (1976) The Halpin-Tsai equations: a review. Polym Eng Sci 16:344–352. doi:10.1002/pen.760160512

Akhavan O, Ghaderi E (2010) Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 4:5731–5736

Alemdar A, Sain M (2008) Biocomposites from wheat straw nanofibers: morphology, thermal and mechanical properties. Compos Sci Technol 68:557–565

Alexandre B, Langevin D, Médéric P et al (2009) Water barrier properties of polyamide 12/montmorillonite nanocomposite membranes: structure and volume fraction effects. J Membr Sci 328:186–204

An J, Zhang M, Wang S, Tang J (2008) Physical, chemical and microbiological changes in stored green asparagus spears as affected by coating of silver nanoparticles-PVP. LWT-Food Sci Technol 41:1100–1107

Angles MN, Dufresne A (2000) Plasticized starch/tunicin whiskers nanocomposites. 1. Structural analysis. Macromolecules 33:8344–8353

Angles MN, Dufresne A (2001) Plasticized starch/tunicin whiskers nanocomposite materials. 2. Mechanical behavior. Macromolecules 34:2921–2931

Ashori A (2014) Effects of graphene on the behavior of chitosan and starch nanocomposite films. Polym Eng Sci 54:2258–2263

Ashori A, Bahrami R (2014) Modification of physico-mechanical properties of chitosan-tapioca starch blend films using nano graphene. Polym-Plast Technol Eng 53:312–318

Avella M, De Vlieger JJ, Errico ME et al (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93:467–474

Azeredo H, Mattoso LHC, Wood D et al (2009) Nanocomposite edible films from mango puree reinforced with cellulose nanofibers. J Food Sci 74:N31–N35

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Barrett J (2014) Physical and biochemical strategies for improving the yield and material properties of Polyhydroxyalkanoate Biopolymers

Barrett JSF, Abdala AA, Srienc F (2014) Poly(hydroxyalkanoate) Elastomers and their Graphene nanocomposites. Macromolecules 47:3926–3941. doi:10.1021/ma500022x

Bharadwaj RK, Mehrabi AR, Hamilton C et al (2002) Structure–property relationships in cross-linked polyester–clay nanocomposites. Polymer 43:3699–3705

Bin Y, Mine M, Koganemaru A et al (2006) Morphology and mechanical and electrical properties of oriented PVA–VGCF and PVA–MWNT composites. Polymer 47:1308–1317

Boehm H-P (2010) Graphene—how a laboratory curiosity suddenly became extremely interesting. Angew Chem Int Ed 49:9332–9335

Brodie BC (1859) On the atomic weight of graphite. Philos Trans R Soc Lond 149:249–259

Brody AL (2006) Nano and food packaging technologies converge

Cabedo L, Giménez E, Lagaron JM et al (2004) Development of EVOH-kaolinite nanocomposites. Polymer 45:5233–5238. doi:10.1016/j.polymer.2004.05.018

Cabedo L, Luis Feijoo J, Pilar Villanueva M et al (2006) Optimization of biodegradable nanocomposites based on a PLA/PCL blends for food packaging applications. In: Macromolecular Symposia. Wiley Online Library, pp 191–197

Cao Y, Feng J, Wu P (2010) Preparation of organically dispersible graphene nanosheet powders through a lyophilization method and their poly(lactic acid) composites. Carbon 48:3834–3839

Celzard A, Mareche JF, Furdin G, Puricelli S (2000) Electrical conductivity of anisotropic expanded graphite-based monoliths. J Phys D Appl Phys 33:3094

Chen B, Evans JRG (2005) Thermoplastic starch–clay nanocomposites and their characteristics. Carbohyd Polym 61:455–463. doi:10.1016/j.carbpol.2005.06.020

Chen P, Zhang L (2006) Interaction and properties of highly exfoliated soy protein/montmorillonite nanocomposites. Biomacromolecules 7:1700–1706

Chen G, Weng W, Wu D et al (2004) Preparation and characterization of graphite nanosheets from ultrasonic powdering technique. Carbon 42:753–759

Chen W, Tao X, Xue P, Cheng X (2005) Enhanced mechanical properties and morphological characterizations of poly(vinyl alcohol)–carbon nanotube composite films. Appl Surf Sci 252:1404–1409

Chen Y, Cao X, Chang PR, Huneault MA (2008) Comparative study on the films of poly(vinyl alcohol)/pea starch nanocrystals and poly(vinyl alcohol)/native pea starch. Carbohyd Polym 73:8–17

Chiu W-M, Chang Y-A, Kuo H-Y et al (2008) A study of carbon nanotubes/biodegradable plastic polylactic acid composites. J Appl Polym Sci 108:3024–3030. doi:10.1002/app.27796

Chung DDL (2016) A review of exfoliated graphite. J Mater Sci 51:554–568

Cyras VP, Manfredi LB, Ton-That M-T, Vázquez A (2008) Physical and mechanical properties of thermoplastic starch/montmorillonite nanocomposite films. Carbohyd Polym 73:55–63. doi:10.1016/j.carbpol.2007.11.014

Dai J, Wang G, Ma L, Wu C (2015) Study on the surface energies and dispersibility of graphene oxide and its derivatives. J Mater Sci 50:3895–3907

Damm C, Münstedt H, Rösch A (2007) Long-term antimicrobial polyamide 6/silver-nanocomposites. J Mater Sci 42:6067–6073

De Azeredo HMC (2009) Nanocomposites for food packaging applications. Food Res Int 42:1240–1253. doi:10.1016/j.foodres.2009.03.019

de Carvalho AJF, Curvelo AAS, Agnelli JAM (2001) A first insight on composites of thermoplastic starch and kaolin. Carbohyd Polym 45:189–194. doi:10.1016/S0144-8617(00)00315-5

de Moura MR, Aouada FA, Avena-Bustillos RJ et al (2009) Improved barrier and mechanical properties of novel hydroxypropyl methylcellulose edible films with chitosan/tripolyphosphate nanoparticles. J Food Eng 92:448–453

de Souza Lima MM, Borsali R (2004) Rodlike cellulose microcrystals: structure, properties, and applications. Macromol Rapid Commun 25:771–787

Dean K, Yu L (2005) Biodegradable protein-nanoparticles composites. Biodegradable polymers for industrial applications. Woodhead Publishing Ltd, Cambridge, UK, pp 289–312

Dervishi E, Biris AR, Watanabe F et al (2011) Few-layer nano-graphene structures with large surface areas synthesized on a multifunctional Fe:Mo:MgO catalyst system. J Mater Sci 47:1910–1919. doi:10.1007/s10853-011-5980-z

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39:228–240

Dubief D, Samain E, Dufresne A (1999) Polysaccharide microcrystals reinforced amorphous poly(β-hydroxyoctanoate) nanocomposite materials. Macromolecules 32:5765–5771

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose microfibrils from potato tuber cells: processing and characterization of starch–cellulose microfibril composites. J Appl Polym Sci 76:2080–2092

Dufresne A, Vignon MR (1998) Improvement of starch film performances using cellulose microfibrils. Macromolecules 31:2693–2696

Dujardin E, Blaseby M, Mann S (2003) Synthesis of mesoporous silica by sol–gel mineralisation of cellulose nanorod nematic suspensions. J Mater Chem 13:696–699

Duncan TV, Pillai K (2014) Release of engineered nanomaterials from polymer nanocomposites: diffusion, dissolution, and desorption. ACS Appl Mater Interfaces 7:2–19

Faghihi S, Gheysour M, Karimi A, Salarian R (2014) Fabrication and mechanical characterization of graphene oxide-reinforced poly(acrylic acid)/gelatin composite hydrogels. J Appl Phys 115:083513

Fang M, Wang K, Lu H et al (2010) Single-layer graphene nanosheets with controlled grafting of polymer chains. J Mater Chem 20:1982–1992

Favier V, Cavaille JY, Canova GR, Shrivastava SC (1997) Mechanical percolation in cellulose whisker nanocomposites. Polym Eng Sci 37:1732–1739

Guan G, Lu J, Jiang H (2016) Preparation, characterization, and physical properties of graphene nanosheets and films obtained from low-temperature expandable graphite. J Mater Sci 51:926–936

Guo J, Liu J, Yang B et al (2015) Biodegradable junctionless transistors with extremely simple structure. Electron Device Lett IEEE 36:908–910

He L, Wang H, Xia G et al (2014) Chitosan/graphene oxide nanocomposite films with enhanced interfacial interaction and their electrochemical applications. Appl Surf Sci 314:510–515

He Y, Zhang N, Gong Q et al (2012) Alginate/graphene oxide fibers with enhanced mechanical strength prepared by wet spinning. Carbohyd Polym 88:1100–1108

Helbert W, Cavaille JY, Dufresne A (1996) Thermoplastic nanocomposites filled with wheat straw cellulose whiskers. Part I: processing and mechanical behavior. Polym Compos 17:604–611

Hu AW, Fu ZH (2003) Nanotechnology and its application in packaging and packaging machinery. Packag Eng 24:22–24

Hu W, Peng C, Luo W et al (2010) Graphene-based antibacterial paper. ACS nano 4:4317–4323

Huang H-D, Liu C-Y, Li D et al (2014) Ultra-low gas permeability and efficient reinforcement of cellulose nanocomposite films by well-aligned graphene oxide nanosheets. J Mater Chem A 2:15853–15863

Huang L, Li D-Q, Lin Y-J et al (2005) Controllable preparation of Nano-MgO and investigation of its bactericidal properties. J Inorg Biochem 99:986–993

Huang M, Yu J, Ma X (2006) High mechanical performance MMT-urea and formamide-plasticized thermoplastic cornstarch biodegradable nanocomposites. Carbohyd Polym 63:393–399

Hubbe MA, Rojas OJ, Lucia LA, Sain M (2008) Cellulosic nanocomposites: a review. BioResources 3:929–980

Jang BZ, Zhamu A (2008) Processing of nanographene platelets (NGPs) and NGP nanocomposites: a review. J Mater Sci 43:5092–5101

Jayasena B, Reddy CD, Subbiah S (2013) Separation, folding and shearing of graphene layers during wedge-based mechanical exfoliation. Nanotechnology 24:205301. doi:10.1088/0957-4484/24/20/205301

Jeon GW, An J-E, Jeong YG (2012) High performance cellulose acetate propionate composites reinforced with exfoliated graphene. Compos B Eng 43:3412–3418

Jiang B, Liu C, Zhang C et al (2007) The effect of non-symmetric distribution of fiber orientation and aspect ratio on elastic properties of composites. Compos B Eng 38:24–34

Jones P, Clarke-Hill C, Shears P et al (2004) Radio frequency identification in the UK: opportunities and challenges. Int J Retail Distrib Manag 32:164–171

Kang S, Pinault M, Pfefferle LD, Elimelech M (2007) Single-walled carbon nanotubes exhibit strong antimicrobial activity. Langmuir 23:8670–8673

Kaplan DL (1998) Introduction to biopolymers from renewable resources. In: Kaplan DDL (ed) Biopolymers from renewable resources. Springer, Berlin Heidelberg, pp 1–29

Kim I-H, Jeong YG (2010) Polylactide/exfoliated graphite nanocomposites with enhanced thermal stability, mechanical modulus, and electrical conductivity. J Polym Sci, Part B: Polym Phys 48:850–858

Kim JY, Han SI, Hong S (2008) Effect of modified carbon nanotube on the properties of aromatic polyester nanocomposites. Polymer 49:3335–3345

Krishnan D, Kim F, Luo J et al (2012) Energetic graphene oxide: challenges and opportunities. Nano today 7:137–152

Kuan C-F, Kuan H-C, Ma C-CM, Chen C-H (2008) Mechanical and electrical properties of multi-wall carbon nanotube/poly(lactic acid) composites. J Phys Chem Solids 69:1395–1398. doi:10.1016/j.jpcs.2007.10.060

Kumar R, Münstedt H (2005) Silver ion release from antimicrobial polyamide/silver composites. Biomaterials 26:2081–2088

Kumar B, Castro M, Feller JF (2012) Poly(lactic acid)–multi-wall carbon nanotube conductive biopolymer nanocomposite vapour sensors. Sens Actuators B: Chem 161:621–628. doi:10.1016/j.snb.2011.10.077

Kvien I, Oksman K (2007) Orientation of cellulose nanowhiskers in polyvinyl alcohol. Appl Phys A 87:641–643

Lau AK-T, Hui D (2002) The revolutionary creation of new advanced materials—carbon nanotube composites. Compos B Eng 33:263–277

Le T, Lakafosis V, Lin Z et al (2012) Inkjet-printed graphene-based wireless gas sensor modules. In: 2012 IEEE 62nd electronic components and technology conference, 1003–1008

Lerf A, He H, Forster M, Klinowski J (1998) Structure of graphite oxide revisited||. J Phys Chem B 102:4477–4482

Liau SY, Read DC, Pugh WJ et al (1997) Interaction of silver nitrate with readily identifiable groups: relationship to the antibacterialaction of silver ions. Lett Appl Microbiol 25:279–283

Li H, Li F, Wang L et al (2009) Effect of nano-packing on preservation quality of Chinese jujube (Ziziphus jujuba Mill. var. inermis (Bunge) Rehd). Food Chem 114:547–552

Li R, Liu C, Ma J (2011) Studies on the properties of graphene oxide-reinforced starch biocomposites. Carbohyd Polym 84:631–637

Liu X, Sun Q, Wang H et al (2005) Microspheres of corn protein, zein, for an ivermectin drug delivery system. Biomaterials 26:109–115. doi:10.1016/j.biomaterials.2004.02.013

Liu L, Shen Z, Liang S et al (2014) Graphene for reducing bubble defects and enhancing mechanical properties of graphene/cellulose acetate composite films. J Mater Sci 49:321–328

Ljungberg N, Bonini C, Bortolussi F et al (2005) New nanocomposite materials reinforced with cellulose whiskers in atactic polypropylene: effect of surface and dispersion characteristics. Biomacromolecules 6:2732–2739

Lu Y, Weng L, Zhang L (2004) Morphology and properties of soy protein isolate thermoplastics reinforced with chitin whiskers. Biomacromolecules 5:1046–1051

Luduena LN, Alvarez VA, Vazquez A (2007) Processing and microstructure of PCL/clay nanocomposites. Mater Sci Eng, A 460:121–129

Luecha J, Hsiao A, Brodsky S et al (2011) Green microfluidic devices made of corn proteins. Lab Chip 11:3419–3425

Luecha J, Sozer N, Kokini JL (2010) Synthesis and properties of corn zein/montmorillonite nanocomposite films. J Mater Sci 45:3529–3537. doi:10.1007/s10853-010-4395-6

Luo PG, Stutzenberger FJ (2008) Nanotechnology in the detection and control of microorganisms. Adv Appl Microbiol 63:145–181

Ma X, Yu J, Wang N (2008) Glycerol plasticized-starch/multiwall carbon nanotube composites for electroactive polymers. Compos Sci Technol 68:268–273. doi:10.1016/j.compscitech.2007.03.016

Ma T, Chang PR, Zheng P, Ma X (2013) The composites based on plasticized starch and graphene oxide/reduced graphene oxide. Carbohyd Polym 94:63–70

Mahmoudian S, Wahit MU, Imran M et al (2012) A facile approach to prepare regenerated cellulose/graphene nanoplatelets nanocomposite using room-temperature ionic liquid. J Nanosci Nanotechnol 12:5233–5239

Mark JE (1996) Ceramic-reinforced polymers and polymer-modified ceramics. Polym Eng Sci 36:2905–2920

Mirzadeh A, Kokabi M (2007) The effect of composition and draw-down ratio on morphology and oxygen permeability of polypropylene nanocomposite blown films. Eur Polymer J 43:3757–3765. doi:10.1016/j.eurpolymj.2007.06.014

Mittal V (2007) Polypropylene-layered silicate nanocomposites: filler matrix interactions and mechanical properties. J Thermoplast Compos Mater 20:575–599

Mittal V (2008) Mechanical and gas permeation properties of compatibilized polypropylene–layered silicate nanocomposites. J Appl Polym Sci 107:1350–1361

Nachay K (2007) Analyzing nanotechnology. Food Technol 61:34–36

Nie L, Liu C, Wang J et al (2015) Effects of surface functionalized graphene oxide on the behavior of sodium alginate. Carbohyd Polym 117:616–623

Novoselov KS, Geim AK, Morozov SV et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Pan Y, Wu T, Bao H, Li L (2011) Green fabrication of chitosan films reinforced with parallel aligned graphene oxide. Carbohyd Polym 83:1908–1915

Paralikar SA, Simonsen J, Lombardi J (2008) Poly(vinyl alcohol)/cellulose nanocrystal barrier membranes. J Membr Sci 320:248–258

Park S, Ruoff RS (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4:217–224

Park H-M, Li X, Jin C-Z et al (2002) Preparation and properties of biodegradable thermoplastic starch/clay hybrids. Macromol Mater Eng 287:553–558

Petersson L, Oksman K (2006) Preparation and properties of biopolymer-based nanocomposite films using microcrystalline cellulose. In: ACS symposium series. Oxford University Press, pp 132–150

Petersen K, Væggemose Nielsen P, Bertelsen G et al (1999) Potential of biobased materials for food packaging. Trends Food Sci Technol 10:52–68. doi:10.1016/S0924-2244(99)00019-9

Pinto AM, Cabral J, Tanaka DAP et al (2013a) Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly(lactic acid) films. Polym Int 62:33–40

Pinto AM, Moreira S, Gonçalves IC et al (2013b) Biocompatibility of poly(lactic acid) with incorporated graphene-based materials. Colloids Surf, B 104:229–238

Podsiadlo P, Choi S-Y, Shim B et al (2005) Molecularly engineered nanocomposites: layer-by-layer assembly of cellulose nanocrystals. Biomacromol 6:2914–2918

Pötschke P, Abdel-Goad* M, Pegel S et al (2009) Comparisons among electrical and rheological properties of melt-mixed composites containing various carbon nanostructures. J Macromol Sci Part A 47:12–19

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52:5–25

Qi L, Xu Z, Jiang X et al (2004) Preparation and antibacterial activity of chitosan nanoparticles. Carbohyd Res 339:2693–2700

Qian C, Sun J, Yang J, Gao Y (2015) Flexible organic field-effect transistors on biodegradable cellulose paper with efficient reusable ion gel dielectrics. RSC Adv 5:14567–14574

Ray SS, Bandyopadhyay J, Bousmina M (2007) Thermal and thermomechanical properties of poly [(butylene succinate)-co-adipate] nanocomposite. Polym Degrad Stab 92:802–812

Ray SS, Yamada K, Okamoto M, Ueda K (2003) New polylactide-layered silicate nanocomposites. 2. Concurrent improvements of material properties, biodegradability and melt rheology. Polymer 44:857–866

Rhim J-W, Ng PKW (2007) Natural biopolymer-based nanocomposite films for packaging applications. Crit Rev Food Sci Nutr 47:411–433. doi:10.1080/10408390600846366

Rhim J-W, Lee J-H, Kwak H-S (2005) Mechanical and water barrier properties of soy protein and clay mineral composite films. Food Sci Biotechnol 14:112–116

Rouf TB, Kokini JL (2016) Biodegradable biopolymer–graphene nanocomposites. J Mater Sci 51:9915–9945

Ruan D, Zhang L, Zhang Z, Xia X (2004) Structure and properties of regenerated cellulose/tourmaline nanocrystal composite films. J Polym Sci Part B: Polym Phys 42:367–373

Ruiz-Garcia L, Lunadei L (2011) The role of RFID in agriculture: applications, limitations and challenges. Comput Electron Agric 79:42–50

Samir MASA, Alloin F, Sanchez J-Y, Dufresne A (2004) Cellulose nanocrystals reinforced poly(oxyethylene). Polymer 45:4149–4157

Sanchez-Garcia MD, Gimenez E, Lagaron JM (2008) Morphology and barrier properties of solvent cast composites of thermoplastic biopolymers and purified cellulose fibers. Carbohyd Polym 71:235–244

Sarac A, Absi N, Dauzère-Pérès S (2010) A literature review on the impact of RFID technologies on supply chain management. Int J Prod Econ 128:77–95

Shokrieh MM, Esmkhani M, Shahverdi HR, Vahedi F (2013) Effect of graphene nanosheets (GNS) and graphite nanoplatelets (GNP) on the Mechanical properties of epoxy nanocomposites. Sci Adv Mater 5:260–266

Shukla R, Cheryan M (2001) Zein: the industrial protein from corn. Ind Crops Prod 13:171–192

Si H, Luo H, Xiong G et al (2014) One-step in situ biosynthesis of graphene oxide-bacterial cellulose nanocomposite hydrogels. Macromol Rapid Commun 35:1706–1711

Sinclair RG (1996) The case for polylactic acid as a commodity packaging plastic. J Macromol Sci Part A 33:585–597. doi:10.1080/10601329608010880

Singh V, Joung D, Zhai L et al (2011) Graphene based materials: past, present and future. Prog Mater Sci 56:1178–1271

Song K, Zhao X, Xu Y, Liu H (2013) Modification of graphene oxide via photo-initiated grafting polymerization. J Mater Sci 48:5750–5755

Sriupayo J, Supaphol P, Blackwell J, Rujiravanit R (2005) Preparation and characterization of α-chitin whisker-reinforced chitosan nanocomposite films with or without heat treatment. Carbohyd Polym 62:130–136

Stanier DC, Patil AJ, Sriwong C et al (2014) The reinforcement effect of exfoliated graphene oxide nanoplatelets on the mechanical and viscoelastic properties of natural rubber. Compos Sci Technol 95:59–66

Staudenmaier L (1898) Verfahren zur darstellung der graphitsäure. Ber Dtsch Chem Ges 31:1481–1487

Svagan AJ, Hedenqvist MS, Berglund L (2009) Reduced water vapour sorption in cellulose nanocomposites with starch matrix. Compos Sci Technol 69:500–506

Szabó T, Berkesi O, Forgó P et al (2006) Evolution of surface functional groups in a series of progressively oxidized graphite oxides. Chem Mater 18:2740–2749. doi:10.1021/cm060258

Terzopoulou Z, Kyzas GZ, Bikiaris DN (2015) Recent advances in nanocomposite materials of graphene derivatives with polysaccharides. Materials 8:652–683

Thakur S, Karak N (2013) Bio-based tough hyperbranched polyurethane–graphene oxide nanocomposites as advanced shape memory materials. RSC Adv 3:9476–9482

Thellen C, Orroth C, Froio D et al (2005) Influence of montmorillonite layered silicate on plasticized poly(l-lactide) blown films. Polymer 46:11716–11727. doi:10.1016/j.polymer.2005.09.057

Tian M, Qu L, Zhang X et al (2014) Enhanced mechanical and thermal properties of regenerated cellulose/graphene composite fibers. Carbohyd Polym 111:456–462

Uyama H, Kuwabara M, Tsujimoto T et al (2003) Green nanocomposites from renewable resources: plant oil-clay hybrid materials. Chem Mater 15:2492–2494

Vanderroost M, Ragaert P, Devlieghere F, De Meulenaer B (2014) Intelligent food packaging: the next generation. Trends Food Sci Technol 39:47–62

Villmow T, Pötschke P, Pegel S et al (2008) Influence of twin-screw extrusion conditions on the dispersion of multi-walled carbon nanotubes in a poly(lactic acid) matrix. Polymer 49:3500–3509. doi:10.1016/j.polymer.2008.06.010

Wang B, Sain M (2007) Isolation of nanofibers from soybean source and their reinforcing capability on synthetic polymers. Compos Sci Technol 67:2521–2527

Wang H, Qiu Z (2011) Crystallization behaviors of biodegradable poly(l-lactic acid)/graphene oxide nanocomposites from the amorphous state. Thermochim Acta 526:229–236

Wang H, Qiu Z (2012) Crystallization kinetics and morphology of biodegradable poly(l-lactic acid)/graphene oxide nanocomposites: influences of graphene oxide loading and crystallization temperature. Thermochim Acta 527:40–46

Weiss J, Takhistov P, McClements DJ (2006) Functional materials in food nanotechnology. J Food Sci 71:R107–R116. doi:10.1111/j.1750-3841.2006.00195.x

William S, Hummers JR, Offeman RE, others (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Xu Y, Zhou J, Hanna MA (2005) Melt-intercalated starch acetate nanocomposite foams as affected by type of organoclay 1. Cereal Chem 82:105–110

Yadav M, Rhee KY, Jung IH, Park SJ (2013) Eco-friendly synthesis, characterization and properties of a sodium carboxymethyl cellulose/graphene oxide nanocomposite film. Cellulose 20:687–698

Yadav M, Rhee KY, Park SJ (2014) Synthesis and characterization of graphene oxide/carboxymethylcellulose/alginate composite blend films. Carbohyd Polym 110:18–25

Yang J-H, Lin S-H, Lee Y-D (2012) Preparation and characterization of poly(l-lactide)–graphene composites using the in situ ring-opening polymerization of PLLA with graphene as the initiator. J Mater Chem 22:10805–10815

Yasmin A, Luo J-J, Daniel IM (2006) Processing of expanded graphite reinforced polymer nanocomposites. Compos Sci Technol 66:1182–1189

Yoon JT, Jeong YG, Lee SC, Min BG (2009) Influences of poly(lactic acid)-grafted carbon nanotube on thermal, mechanical, and electrical properties of poly(lactic acid). Polym Adv Technol 20:631–638. doi:10.1002/pat.1312

Yoon S-Y, Deng Y (2006) Clay–starch composites and their application in papermaking. J Appl Polym Sci 100:1032–1038

Yoon OJ, Jung CY, Sohn IY et al (2011) Nanocomposite nanofibers of poly(d, l-lactic-co-glycolic acid) and graphene oxide nanosheets. Compos A Appl Sci Manuf 42:1978–1984

Yu J, Cui G, Wei M, Huang J (2007) Facile exfoliation of rectorite nanoplatelets in soy protein matrix and reinforced bionanocomposites thereof. J Appl Polym Sci 104:3367–3377. doi:10.1002/app.25969

Zeng H, Gao C, Wang Y et al (2006) In situ polymerization approach to multiwalled carbon nanotubes-reinforced nylon 1010 composites: mechanical properties and crystallization behavior. Polymer 47:113–122

Zhang X, Liu X, Zheng W, Zhu J (2012) Regenerated cellulose/graphene nanocomposite films prepared in DMAC/LiCl solution. Carbohyd Polym 88:26–30

Zheng W, Lu X, Wong S-C (2004) Electrical and mechanical properties of expanded graphite-reinforced high-density polyethylene. J Appl Polym Sci 91:2781–2788

Zheng P, Ma T, Ma X (2013) Fabrication and properties of starch-grafted graphene nanosheet/plasticized-starch composites. Ind Eng Chem Res 52:14201–14207

Zhou X, Shin E, Wang KW, Bakis CE (2004) Interfacial damping characteristics of carbon nanotube-based composites. Compos Sci Technol 64:2425–2437. doi:10.1016/j.compscitech.2004.06.001

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6:754–761

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Rouf, T.B., Kokini, J.L. (2018). Natural Biopolymer-Based Nanocomposite Films for Packaging Applications. In: Jawaid, M., Swain, S. (eds) Bionanocomposites for Packaging Applications. Springer, Cham. https://doi.org/10.1007/978-3-319-67319-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-67319-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-67318-9

Online ISBN: 978-3-319-67319-6

eBook Packages: EngineeringEngineering (R0)