Abstract

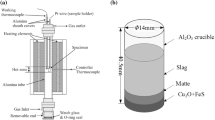

Smelting is an important process in copper production to produce matte and slag. The slag, containing about 1–12% Cu, can be further processed to recover the copper contaminated, but recycle of the slag concentrate reduces overall productivity and efficiency of the operation. The best solution is to minimize the copper loss to the slag. The entrained matte droplets in copper smelting slag may originate from a few sources. The present study aims to investigate possible copper matte loss mechanisms by visualization of room temperature experiments and high-temperature examination. It is believed that the gas bubbles from the matte phase disperse the matte droplets into the slag causing entrained matte in slag. Analyses of quenched slags from industrial operation and laboratory experiments confirmed that matte droplets in the slag are extensively associated with the gas bubbles. Water model is used to simulate the procedure and the bubble behaviors at the liquid-liquid interface are observed experimentally with a high-speed camera.

Similar content being viewed by others

References

D. Poggi, R. Minto, W.G. Davenport, Mechanisms of metal entrapment in slags. J. Met. 21(11), 40–45 (1969)

R. Minto, W.G. Davenport, Entrapment and flotation of matte in molten slags. Inst. Min. Metall. Trans. Sect. C 81, C36–C42 (1972)

M. Kemiha, E. Olmos, W. Fei, S. Poncin, H.Z. Li, Passage of a gas bubble through a liquid-liquid interface. Ind. Eng. Chem. Res. 46(19), 6099–6104 (2007)

Roland Clift, J.R. Grace, M.E. Weber, Bubbles, drops, and particles (Dover Publications, INC., New York, NY, 2005), pp. 30–34

C. Bale, E. Bélisle, P. Chartrand, S. Degterov, G. Eriksson, K. Hack, I.H. Jung, Y.B. Kang, J. Melançon, A. Pelton, FactSage thermochemical software and databases—recent developments. Calphad 33, 295–311 (2009)

E. De Wilde, I. Bellemans, L. Zheng, M. Campforts, M. Guo, B. Blanpain, N. Moelans, K. Verbeken, Origin and sedimentation of Cu-droplets sticking to spinel solids in pyrometallurgical slags. Mater. Sci. Technol. (2016). doi:10.1080/02670836.2016.1151998

M. Chen, B. Zhao, Phase equilibrium Studies of “Cu2O”–SiO2–Al2O3 system in equilibrium with metallic copper. J. Am. Ceram. Soc. 96(11), 3631–3636 (2013)

P. George, A.V. Nguyen, G.J. Jameson, Assessment of true flotation and entrainment in the flotation of submicron particles by fine bubbles. Miner. Eng. 17(7–8), 847–853 (2004)

G.K. Bachelor, F.R.S., An Introduction to Fluid Dynamics (Cambridge, UK: Cambridge University Press, 1967), pp. 378–380

Acknowledgements

The authors would like to thank National Copper Corporation of Chile (Codelco), Dongying Fangyuan Nonferrous Metals (Fangyuan) and Australia Research Council for financial support through the ARC Linkage program. The authors also would like to thank China Scholarship Council (CSC) and The University of Queensland to provide Xiangfeng Cheng scholarship.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Cheng, X., Cui, Z., Contreras, L., Chen, M., Nguyen, A., Zhao, B. (2017). Introduction of Matte Droplets in Copper Smelting Slag. In: Hwang, JY., et al. 8th International Symposium on High-Temperature Metallurgical Processing. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-51340-9_37

Download citation

DOI: https://doi.org/10.1007/978-3-319-51340-9_37

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51339-3

Online ISBN: 978-3-319-51340-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)