Abstract

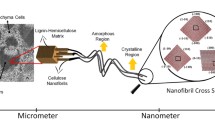

Bamboo, a grass, with stiffness-to-weight and strength-to-weight ratios higher than steel and concrete is a wonder of nature. In this chapter we present a comprehensive review of the mechanical properties of bamboo from nano- to macroscale. After presenting the main toughening mechanisms in bamboo, we present a summary of the atomistic simulations of bamboo microfibril which is the main sources of stiffness and strength in bamboo fibers. The role of humidity in bamboo microfibril is also presented at small scale. It is shown experimentally and numerically that the addition of 1% moisture content to the system does not change density and increases the elastic modulus in the longitudinal direction. This is probably due to the relatively larger fractional free volume in the structure of lignin, and subsequently LCC, at low moisture contents. This interesting phenomenon is important in understanding the mechanics of bamboo microfibrils.

Similar content being viewed by others

References

Adler E (1977) Lignin chemistry–past, present and future. Wood Sci Technol 11:169–218

Amada S, Untao S (2001) Fracture properties of bamboo. Compos Part B Eng 32(5):451–459

Amada S, Ichikawa Y, Munekata T, Nagase Y, Shimizu H (1997) Fiber texture and mechanical graded structure of bamboo. Compos Part B Eng 28(1):13–20

Askarinejad S, Kotowski P, Shalchy F, Rahbar N (2015) Effects of humidity on shear behavior of bamboo. Theor Appl Mech Lett 5(6):236–243

Bai XS, Lee AWC, Thompson LL, Rosowsky DV (1999) Finite element analysis of moso bamboo-reinforced southern pine OSB composite team. Wood Fiber Sci 31:403

Basu P (2007) Microscopes made from bamboo bring biology into focus. Nat Med 13:1128

Batsanov SS (2001) Van der Waals radii of elements. Inorg Mater 37:871–885

Bergander A, Salmen LJ (2002) Cell wall properties and their effects on the mechanical properties of fibers. Mater Sci 37:151–156

Bertinetti L, Hangen UD, Eder M, Leibner P, Fratzl P, Zlotnikov I (2015) Characterizing moisture-dependent mechanical properties of organic materials: humidity-controlled static and dynamic nanoindentation of wood cell walls. Philos Mag 95:1992–1998

Besombes S, Mazeau K (2005a) The cellulose/lignin assembly assessed by molecular modeling. Part 1: adsorption of a threo guaiacyl β-O-4 dimer onto a Iβ cellulose whisker. Plant Physiol Biochem 43:299–308

Besombes S, Mazeau K (2005b) The cellulose/lignin assembly assessed by molecular modeling. Part 2: seeking for evidence of organization of lignin molecules at the interface with cellulose. Plant Physiol Biochem 43:277–286

Bloyer DR, Rao KTV, Ritchie RO (1998) Fracture toughness and R-curve behavior of laminated brittle-matrix composites. Metall Mater Trans A 29A(10):2483–2496

Bloyer DR, Rao KTV, Ritchie RO (1999) Fatigue-crack propagation behavior of ductile/brittle laminated composites. Metall Mater Trans A 30A(3):633–642

Bondi A (1966) Van der Waals volumes and radii of metals in covalent compounds. J Phys Chem 70:3006–3007

Brauns F (1962) Soluble native lignin, milled wood lignin, synthetic lignin, and the structure of lignin. Holzforschung Int J Biol Chem Phys Technol Wood 16:97–102

Budiansky B, Amazigo JC, Evans AG (1988) Small-scale crack bridging and the fracture toughness of particulate-reinforced ceramics. J Mech Phys Solids 36(2):167–187

Buehler M (2008) Atomistic modeling of materials failure. Springer Science & Business Media, Boston

Chang ST, Wang SY, Wu JH (1998) Rapid extraction of epidermis chlorophyll of moso bamboo (Phyllostachys pubescens) culm using ultrasonics. J Wood Sci 44(1):78–80

Chung KF, Yu WK, Chan SL (2002) Mechanical properties and engineering data of structural bamboo. In: Proceedings of international seminar – bamboo scaffolds in building construction

Chung MJ, Cheng SS, Lee CJ, Chang ST (2014) Novel methods for dyeing the epidermis of bamboo culms and their colour fastness. Color Technol 130(2):112–119

Ciesielski PN, Matthews JF, Tucker MP, Beckham GT, Crowley MF, Himmel ME, Donohoe BS (2013) 3D electron tomography of pretreated biomass informs atomic modeling of cellulose microfibrils. ACS Nano 7(9):8011–8019

Connolly ML (1985) Computation of molecular volume. J Am Chem Soc 107:1118–1124

Cousins W (1976) Elastic modulus of lignin as related to moisture content. Wood Sci Technol 10:9–17

Cousins WJ (1977) Elasticity of isolated lignin: young’s modulus by a continuous indentation method. N Z J For Sci 7:107–112

Cousins W (1978) Young’s modulus of hemicellulose as related to moisture content. Wood Sci Technol 12:161–167

Diddens I, Murphy B, Krisch M, Muller M (2008) Anisotropic elastic properties of cellulose measured using inelastic X-ray scattering. Macromolecules 41:9755–9759

Ding SY, Himmel ME (2006) The maize primary cell wall microfibril: a new model derived from direct visualization. J Agric Food Chem 54:597–606

Dixon PG, Gibson LJ (2014) The structure and mechanics of Moso bamboo material. J R Soc Interface 11(99):20140321

Dri F, Hector GJ, Moon R, Zavattieri P (2013) Anisotropy of the elastic properties of crystalline cellulose from first principles density functional theory with Van der Waals interactions. Cellulose 20:2703–2718

Eichhorn SJ, Young RJ, Davies GR (2005) Modeling crystal and molecular deformation in regenerated cellulose fibers. Biomacromolecules 6(1):507–513

Fernandes AN, Thomas LH, Altaner CM, Callow P, Forsyth VT, Apperley DC, Jarvis MC (2011) Nanostructure of cellulose microfibrils in spruce wood. Proc Natl Acad Sci 108(47):E1195–E1203

Fett T, Munz D (1994) Stress intensity factors and weight functions for one dimensional cracks, Report KfK 5290. Karlsruhe: Institut fur Material forschung

Forss K, Fremer KE, Stenlund B (1966) Spruce lignin and its reactions in sulfite cooking. I. Structure of lignin. Pap Puu-pap Och Tra 48:565–574

Geymayer HG, Cox FB (1970) Bamboo reinforced concrete. ACI J Proc 67(10):841–846

Ghavami K (1995) Ultimate load behavior of bamboo-reinforced lightweight concrete beams. Cem Concr Compos 17:281

Ghavami K (2005) Bamboo as reinforcement in structural concrete elements. Cem Concr Compos 27:637–649

Ghavami K, Rodrigues CS, Paciornik S (2003) Bamboo – functionally graded composite material. Asian J Civil Eng 4:1

Gibson LJ (2012) The hierarchical structure and mechanics of plant materials. J R Soc Interface 9(76):2749–2766

Glasser WG, Glasser HR (1974) Simulation of reactions with lignin by computer (Simrel). II. A model for softwood lignin. Holzforschung Int J Biol Chem Phys Technol Wood 28:5–11

Green DW, Kretschmann DE (1994) Moisture content and the properties of clear southern pine. Research paper FPL (USA)

Habibi MK, Lu Y (2014) Crack propagation in bamboo’s hierarchical cellular structure. Scientific reports, 4

Habibi MK, Samaei AT, Gheshlaghi B, Lu J, Lu Y (2015) Asymmetric flexural behavior from bamboo’s functionally graded hierarchical structure: underlying mechanisms. Acta Biomater 16:178–186

He XQ, Suzuki K, Kitamura S, Lin JX, Cui KM, Itoh T (2002) Toward understanding the different function of two types of parenchyma cells in bamboo culms. Plant Cell Physiol 43(2):186–195

Hosoya T, Kawamoto H, Saka S (2007) Cellulose–hemicellulose and cellulose–lignin interactions in wood pyrolysis at gasification temperature. J Anal Appl Pyrolysis 80:118–125

Huang X, Netravali A (2009) Biodegradable green composites made using bamboo micro/nano-fibrils and chemically modified soy protein resin. Compos Sci Technol 69(7):1009–1015

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10:2571–2576

Jager A, Hofstetter K, Buksnowitz C, Gindl-Altmutter W, Konnerth J (2011) Identification of stiffness tensor components of wood cell walls by means of nanoindentation. Compos A Appl Sci Manuf 42:2101–2109

Jain S, Kumar R, Jindal UC (1992) Mechanical behavior of bamboo and bamboo composite. J Mater Sci 27(17):4598–4604

Jakes JE, Hunt CG, Yelle DJ, Lorenz L, Hirth K, Gleber SC, Frihart CR (2015) Synchrotron-based X-ray fluorescence microscopy in conjunction with nanoindentation to study molecular-scale interactions of phenol? Formaldehyde in wood cell walls. ACS Appl Mater Interfaces 7:6584–6589

Janssen JJA (1981) Bamboo in building structures. Doctoral dissertation, Technische Hogeschool Eindhoven

Janssen JJA (1991) Mechanical properties of bamboo. Kluwer Academic Publishers, Dordrecht

Jeffries TW (1990) Biodegradation of lignin-carbohydrate complexes. Biodegradation 1:163

Keogh L, O’Hanlon P, O’Reilly P, Taylor D (2015) Fatigue in Bamboo. Int J Fatigue 75:51–56

Khalil HA, Bhat IUH, Jawaid M, Zaidon A, Hermawan D, Hadi YS (2012) Bamboo fibre reinforced biocomposites: a review. Mater Des 42:353–368

Kulasinski K, Keten S, Churakov SV, Guyer R, Carmeliet J, Derome D (2014a) Molecular mechanism of moisture-induced transition in amorphous cellulose. ACS Macro Lett 3(10):1037–1040

Kulasinski K, Keten S, Churakov SV, Derome D, Carmeliet J (2014b) A comparative molecular dynamics study of crystalline, paracrystalline and amorphous states of cellulose. Cellulose 21:1103–1116

Kulasinski K, Guyer R, Derome D, Carmeliet J (2015) Water adsorption in wood microfibril-hemicellulose system: role of the crystalline-amorphous interface. Biomacromolecules 16:2972–2978

Lahiji RR et al (2010) Atomic force microscopy characterization of cellulose nanocrystals. Langmuir 26:4480–4488

Lakkad SC, Patel JM (1980) Mechanical properties of bamboo, a natural composite. Fibre Sci Tech 14:319

Lee AWC, Bai XS, Bangi AP (1997) Flexural properties of bamboo-reinforced southern pine OSB beams. Forest Prod J 47:74

Li LJ, Wang YP, Wang G, Cheng HT, Han XJ (2010) Evaluation of properties of natural bamboo fiber for application in summer textiles. J Fiber Bioeng Inform 3(2):94–99

Lindner B, Petridis L, Schulz R, Smith JC (2013) Solvent-driven preferential association of lignin with regions of crystalline cellulose in molecular dynamics simulation. Biomacromolecules 14:3390–3398

Lo TY, Cui HZ, Leung HC (2004) The affect of fiber density on strength capacity of bamboo. Mater Lett 58:2595

Lo TY, Cui HZ, Tang PWC, Leu HC (2008) The effect of fiber density on strength capacity of bamboo. Construct Build Mater 22(7):1532–1535

MacKerell AD Jr et al (1998) All-atom empirical potential for molecular modeling and dynamics studies of proteins. J Phys Chem B 102:3586–3616

Maekawa E (1976) Studies on hemicellulose of bamboo. Wood Res-Slovakia 59:153–179

Malherbe S, Cloete T (2002) Lignocellulose biodegradation: fundamentals and applications. Rev Environ Sci Biotechnol 1:105–114

Mannan S, Paul Knox J, Basu S (2017) Correlations between axial stiffness and microstructure of a species of bamboo. R Soc Open Sci 4:160412

Mayo SL, Olafson BD, Goddard WA (1990) DREIDING: a generic force field for molecular simulations. J Phys Chem 94:8897–8909

Miyamoto H, Umemura M, Aoyagi T, Yamane C, Ueda K, Takahashi K (2009) Structural reorganization of molecular sheets derived from cellulose II by molecular dynamics simulations. Carbohydr Res 344(9):1085–1094

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40(7):3941–3994

Nimz H (1974) Beech lignin – proposal of a constitutional scheme. Angew Chem Int Ed Engl 13:313–321

Nogata F, Takahashi H (1995) Intelligent functionally graded material: bamboo. Compos Eng 5(7):743–751

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20

Osorio L, Trujillo E, Van Vuure AW, Verpoest I (2011) Morphological aspects and mechanical properties of single bamboo fibres and flexural characterization of bamboo/epoxy composites. J Reinf Plast Compos 30:0731684410397683

Pakzad A, Yassar R (2013) New frontiers of nanoparticles and nanocomposite materials. Adv Struct Mater 4:233–263

Phong NT, Fujii T, Chuong B, Okubo K (2011) Study on how to effectively extract bamboo fibers from raw bamboo and wastewater treatment. J Mater Sci Res 1(1):144

Pu Y, Zhang D, Singh PM, Ragauskas AJ (2008) The new forestry biofuels sector. Biofuels Bioprod Biorefin 2:58–73

Rao KMM, Rao KM (2007) Extraction and tensile properties of natural fibers: vakka, date and bamboo. Compos Struct 77(3):288–295

Ray AK, Das SK, Mondal S, Ramachandrarao P (2004) Microstructural characterization of bamboo. J Mater Sci 39:1055

Sakakibara A (1980) A structural model of softwood lignin. Wood Sci Technol 14:89–100

Salmen L (2004) Micromechanical understanding of the cell-wall structure. C R Biol 327:873–880

Sathitsuksanoh N, Zhu Z, Ho TJ, Bai MD, Zhang YHP (2010) Special issue on lignocellulosic bioethanol: current status and perspectives. Bioresour Technol 101:4926–4929

Scheller HV, Ulvskov P (2010) Hemicelluloses. Plant Biol 61:263–288

Shao ZP, Fang CH, Tian GL (2009) Mode I interlaminar fracture property of moso bamboo (Phyllostachys pubescens). Wood Sci Technol 43:527–36

Shi Z et al (2013) Isolation and structural exploration of hemicelluloses from the largest bamboo species: dendrocalamus sinicus. Bioresources 8:5036–5050

Silva ECN, Walters MC, Paulino GH (2006) Modeling bamboo as a functionally graded material: lessons for the analysis of affordable materials. J Mater Sci 41(21):6991–7004

Sinko R, Mishra S, Ruiz L, Brandis N, Keten S (2013) Dimensions of biological cellulose nanocrystals maximize fracture strength. ACS Macro Lett 3:64–69

Sturcov A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules 6(2):1055–1061

Sun H (1998) COMPASS: an ab initio force-field optimized for condensed-phase applications: overview with details on alkane and benzene compounds. J Phys Chem B 102:7338–7364

Sun RC, Fang J, Tomkinson J (2000) Delignification of rye straw using hydrogen peroxide. Ind Crop Prod 12:71–83

Suresh S, Mortensen A (1988) Fundamentals of functionally graded materials. IOM Communications, London

Tan T, Rahbar N, Allameh SM, Kwofie S, Dissmore D, Ghavami K, Soboyejo WO (2011) Mechanical properties of functionally graded hierarchical bamboo structures. Acta Biomater 7(10):3796–3803

Taylor D, Kinane B, Sweeney C, Sweetnam D, O’Reilly P, Duan K (2015) The biomechanics of bamboo: investigating the role of the nodes. Wood Sci Technol 49:345–357

Thran A, Kroll G, Faupel F (1999) Correlation between fractional free volume and diffusivity of gas molecules in glassy polymers. J Polym Sci B Polym Phys 37:3344–3358

Vanholme R, Morreel K, Ralph J, Boerjan W (2008) Lignin engineering. Curr Opin Plant Biol 11:278–285

Wang X, Ren H, Zhang B, Fei B, Burgert I (2012a) Cell wall structure and formation of maturing fibres of moso bamboo (Phyllostachys pubescens) increase buckling resistance. J R Soc Interface 9(70):988–996

Wang SG, Lin SY, Pu XL, Ding YL, Wan XC (2012b) Developmental changes in cell wall of bundle sheath fibers close to phloem of Fargesia yunnanensis. Bot Stud 53(3):353–362

Watching Grass Grow The Economist (2018) Innovative materials from bamboo are helping a new industry to sprout.

Wegst UGK (2011) Bending efficiency through property gradients in bamboo, palm, and wood-based composites. J Mech Behav Biomed Mater 4(5):744–755. ISSN:1878-0180

Wegst UGK, Ashby MF (2004) The mechanical efficiency of natural materials. Philos Mag 84(21):2167–2186

Wegst UG, Bai H, Saiz E, Tomsia AP, Ritchie RO (2014) Bioinspired structural materials. Nat Mater 14:23–36

Xiao B, Sun X, Sun R (2001) Chemical, structural, and thermal characterizations of alkali-soluble lignins and hemicelluloses, and cellulose from maize stems, rye straw, and rice straw. Polym Degrad Stab 74:307–319

Xiao Y, Zhou Q, Shan B (2010) Design and construction of modern bamboo bridges. J Bridge Eng 15(5):533–541

Youssefian S, Rahbar N (2015) Molecular origin of strength and stiffness in bamboo fibrils. Sci Rep 5:11116

Youssefian S, Jakes JE, Rahbar N (2017) Variation of nanostructures, molecular interactions, and anisotropic elastic moduli of lignocellulosic cell walls with moisture. Sci Rep 7:2054

Yu D, Tan H, Ruan Y (2011a) A future bamboo-structure residential building prototype in China: life cycle assessment of energy use and carbon emission. Energ Buildings 43(10):2638–2646

Yu Y, Fei B, Wang H, Tian G (2011b) Longitudinal mechanical properties of cell wall of Masson pine (Pinus massoniana Lamb) as related to moisture content: a nanoindentation study. Holzforschung 65:121–126

Yueping W, Ge W, Haitao C, Genlin T, Zheng L, QunFeng X, Xiangqi Z, Xiaojun H, Xushan G (2009) Structures of natural bamboo fiber for textiles. Text Res J 80:334–343

Zachariah EJ, Sabulal B, Nair DNK, Johnson AJ, Kumar CSP (2016) Carbon dioxide emission from bamboo culms. Plant Biol 18:400–405

Zhao YH, Abraham MH, Zissimos AM (2003) Fast calculation of van der Waals volume as a sum of atomic and bond contributions and its application to drug compounds. J Org Chem 68:7368–7373

Zou L, Jin H, Lu WY, Li X (2009) Nanoscale structural and mechanical characterization of the cell wall of bamboo fibers. Mater Sci Eng C 29:1375–1379

Acknowledgements

This work was supported in part by the NSF CAREER grant #1261284.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Section Editor information

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this entry

Cite this entry

Askarinejad, S., Youssefian, S., Rahbar, N. (2019). Toughening and Strengthening Mechanisms in Bamboo from Atoms to Fibers. In: Andreoni, W., Yip, S. (eds) Handbook of Materials Modeling. Springer, Cham. https://doi.org/10.1007/978-3-319-50257-1_88-1

Download citation

DOI: https://doi.org/10.1007/978-3-319-50257-1_88-1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-50257-1

Online ISBN: 978-3-319-50257-1

eBook Packages: Springer Reference Physics and AstronomyReference Module Physical and Materials ScienceReference Module Chemistry, Materials and Physics