Abstract

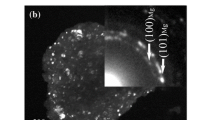

It is extremely difficult to incorporate and disperse nanoparticles (NPs), especially for a high percentage, into metal matrix during solidification processing to achieve crucial property enhancement in metal matrix nanocomposites (MMNCs), mainly due to the strong tendency of NP aggregation. Thus, the significant property enhancement expected by the addition of a high percentage of NPs is rarely achieved in solidification processing of bulk MMNCs. Here we show that an unprecedented uniform distribution of 5 vol.% SiC NPs in Mgl8Sn alloy matrix is obtained by solidification processing. The resulting Mg18Sn matrix nanocomposites exhibits a very high microhardness value of 150 kg/mm2. The results reported in this work shed light on a potential pathway for production of ultrahigh performance metallic nanocomposites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Z. Zhang, D.L. Chen, “Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength,” Scripta Mater., 54 (2006), 1321–1326.

V. Provenzano, R.L. Holtz, “Nanocomposites for high temperature applications,” Mater. Sci. Eng. A, 204 (1995), 125–134.

S.C. Tjong, “Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties,” Adv. Eng. Mater., 9 (2007), 639–652.

J.B. Ferguson, F. Sheykh-Jaberi, C.S. Kim, P.K. Rohatgi, K. Cho, “On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs),” Mater. Sci. Eng. A, 558 (2012), 193–204.

C.S. Kim, I. Sohn, M. Nezafati, J.B. Ferguson, B.F. Schultz, Z. Bajestani-Gohari, P.K. Rohatgi, K. Cho, “Prediction models for the yield strength of particle-reinforced unimodal pure magnesium (Mg) metal matrix nanocomposites (MMNCs),” J. Mater. Sci., 48 (2013), 4191–4204.

H. Ferkel, B.L. Mordike, “Magnesium strengthened by SiC nanoparticles,” Mater. Sei. Eng. A, 298 (2001), 193–199.

C. Capdevila, H. Bhadeshia, “Manufacturing and microstructural evolution of mechanically alloyed oxide dispersion strengthened superalloys,” Adv. Eng. Mater., 3 (2001), 647–656.

R.S. Mishra, Z.Y. Ma, I. Charit, “Friction stir processing: a novel technique for fabrication of surface composite,” Mater. Sci. Eng. A, 341 (2003), 307–310.

R.S. Mishra, Z.Y. Ma, “Friction stir welding and processing,” Mater. Sei. Eng. R, 50 (2005), 1–78.

L.Y. Chen, H. Konishi, A. Fehrenbacher, C. Ma, J.Q. Xu, H. Choi, H.F. Xu, F.E. Pfefferkorn, X.C. Li, “Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites,” Scripta Mater., 67 (2012), 29–32.

L.Y. Chen, H. Choi, A. Fehrenbacher, J.Q. Xu, C. Ma, X.C. Li, “Uniform dispersion of nanoparticles in metal matrix nanocomposites,” in Supplemental Proceedings: Materials Processing and Interfaces, Page 757–763, Volume 1 (ed TMS), John Wiley & Sons, Inc., Hoboken, NJ, USA., (2012).

L.Y. Chen, J.Y. Peng, J.Q. Xu, H. Choi, X.C. Li, “Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing,” Scripta Mater., 69 (2013), 634–637.

Y. Sun, H. Choi, H. Konishi, V. Pikhovich, R. Hathaway, L.Y. Chen, X.C. Li, “Effect of core-shelled nanoparticles of carbon-coated nickel on magnesium,” Mater. Sci. Eng. A, 546 (2012), 284–290.

Y. Yang, J. Lan, X.C. Li, “Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy,” Mater. Sci. Eng. A, 380 (2004), 378–383.

X.C. Li, Y. Yang, X.D. Cheng, “Ultrasonic-assisted fabrication of metal matrix nanocomposites,” J. Mater. Sci., 39 (2004), 3211–3212.

J.Q. Xu, L.Y. Chen, H. Choi, X.C. Li, “Theoretical study and pathways for nanoparticle capture during solidification of metal melt,” J. Phys. Condens. Matter, 24 (2012), 255304.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Chen, LY., Peng, JY., Xu, JQ., Choi, H., Li, XC. (2014). Achieving Uniform Distribution and Dispersion of a High Percentage Nanoparticles in Mg18Sn Matrix by Solidification Processing. In: Alderman, M., Manuel, M.V., Hort, N., Neelameggham, N.R. (eds) Magnesium Technology 2014. Springer, Cham. https://doi.org/10.1007/978-3-319-48231-6_85

Download citation

DOI: https://doi.org/10.1007/978-3-319-48231-6_85

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48589-8

Online ISBN: 978-3-319-48231-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)