Abstract

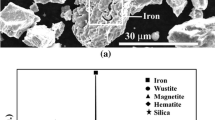

A novel ironmaking process is under development at the University of Utah aimed at producing iron directly from iron oxide concentrate in a flash reactor. This process will reduce hazardous emissions and save energy. The kinetics of magnetite reduction with hydrogen was previously investigated in our laboratory in the temperature range 1150 to 1400 °C at large temperature increments (~100 °C increments). Due to the significant melting that occurs above 1350 °C, the reduction kinetics was measured and analyzed in two distinct temperature ranges of 1150 to 1350 °C and 1350 to 1600 °C (~50 °C increments). Experiments were performed using magnetite concentrate particles of different sizes under various hydrogen partial pressures and residence times. Reduction degrees of more than 90 % were achieved in a few seconds at temperatures as low as 1250 °G Different rate expressions were needed to obtain reliable agreement with experimental data.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

M. Y. Mohassab- Ahmed and H. Y. Sohn, Method and Device for Digestion of Materials in a Microwave Oven, 2012, US Patent App. 61/651.

MY. Mohassab-Ahmed, H. Y. Sohn, “Effect of Water Vapor Content in H2-H2O-CO-CO2 Mxtures on the Equilibrium Distribution of Manganese between CaO-MgOsat-SiO2-Al2Q3-FeO-P2O5 Slag and Molten Iron.” Steel Res. Int., 85 (2014), 875–884.

M.Y. Mohassab Ahmed, “Phase Equilibria between Iron and Slag in CO/CO 2/ H 2 /H 2 O Atmospheres Relevant to a Novel Flash Ironmaking Technology” (PhD Dissertation, The University of Utah, 2013).

M.Y. Mohassab-Ahmed, H. Y Sohn, “Effect of Water Vapor Content in H2-H2O-CO-CO2 Mxtures on the Activity of Iron Oxide in Slags Relevant to a Novel Flash Ironmaking Technology.” Ironmaking Steelmaking, 41(2014), 665 – 675.

Y Mohassab and H. Sohn, “Effect of Water Vapour on Distribution of Phosphorus between liquid Iron and MgO Saturated Slag Relevant to Flash Ironmaking Technology.” Ironmaking Steelmaking, 41 (2014), 575–582.

Y Mohassab and HY. Sohn, “Effect of Water Vapor on Sulfur Distribution between liquid Fe and MgSaturated Slag Relevant to a Flash Ironmaking Technology.” Steel Res. Int., 86 (2014), 753–759.

Y. Mohassab and H.Y. Sohn, “Analysis of Slag Chemistry by FTIRxRAS and Raman Spectroscopy: Effect of Water Vapor Content in H2-H2O-CO-CO2 Mxtures Relevant to a Novel Green Ironmaking Technology.” Steel Res. Int., 86 (2014), 740–752.

M.Y. Mohassab-Ahmed, H.Y. Sohn, and L. Zhu, “Effect of Water Vapour Content in H2-H2O-CO-CO2 Mxtures on MgO Solubility in Slag under Conditions of Novel Flash Ironmaking Technology.” Ironmaking Steelmaking, 41 (2014), 575–582.

F. Chen, Y. Mohassab, T. Jiang, and H.Y. Sohn, “Hydrogen Reduction Kinetics of Hematite Concentrate Particles Relevant to a Novel Hash Ironmaking Process.” Metall. Mater. Trans. B, 46(2015), 1133–1145.

F. Chen, Y. Mohassab, S. Zhang, and H.Y. Sohn, “Kinetics of the Reduction of Hematite Concentrate Particles by Carbon Monoxide Relevant to a Novel Hash Ironmaking Process.” Metall. Mater. Trans. B, 46 (2015), 1716–1728.

H. Wang and H.Y. Sohn, “Hydrogen Reduction Kinetics of Magnetite Concentrate Particles Relevant to a Novel Flash Ironmaking Process.” Metall. Mater. Trans. B, 44 (2012), 133–145.

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2016 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Elzohiery, M., Mohassab, Y., Abdelghany, A., Zhang, S., Chen, F., Sohn, H.Y. (2016). Reduction Kinetics of Magnetite Concentrate Particles with Hydrogen at 1150–1600 °C Relevant to a Novel Flash Ironmaking Process. In: Allanore, A., Bartlett, L., Wang, C., Zhang, L., Lee, J. (eds) EPD Congress 2016. Springer, Cham. https://doi.org/10.1007/978-3-319-48111-1_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-48111-1_5

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48621-5

Online ISBN: 978-3-319-48111-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)