Abstract

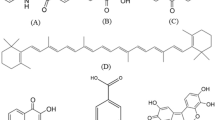

Dyeing of fabrics is one of the most important finishing steps of the textile industry. Fixation of dye over the textile fabric using various chemicals may cause environmental pollution. Generally, the fixation process is highly dependent on the compatibility between fabric and dye. Alkali and salts through which chemical bonds between dyes and fabrics have been conventionally employed for fixing active dye species. Conventional methods have been made to be sustainable by the treatment of fibers with physical techniques including ultrasound, ultraviolet, plasma, and microwave treatments prior to dyeing. Catalytic fixation of dyes using mordants, surfactants, and crosslinkers has been recognized to be promising from a practical point of view. Micellar catalysis has been recently introduced as an efficient, environmentally friendly, and less water-consuming dye fixation protocol. In this chapter, the basic structures and properties of textile fabrics and dyes, the mechanism of fixation of various dyes on different fabrics, and practical examples of sustainable dye fixation are discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ahmed, N. S. (2005). The use of sodium edate in the dyeing of cotton with reactive dyes. Dyes and Pigments, 65(3), 221–225.

Ammayappan, L., Jose, S., & Arputha, R. A. (2016). Sustainable production processes in textile dyeing. Green Fashion, 1, 185–216.

Arivithamani, N., & Dev, V. R. (2018). Characterization and comparison of salt-free reactive dyed cationized cotton hosiery fabrics with that of conventional dyed cotton fabrics. Journal of Cleaner Production, 183, 579–589.

Atav, R. (2013). The use of new technologies in dyeing of proteinous fibers. Eco-friendly Textile Dyeing and Finishing, 16, 103–147.

Bafana, A., Devi, S. S., & Chakrabarti, T. (2011). Azo dyes: Past, present and the future. Environmental Reviews, 19, 350–371.

Bahria, H., & Erbil, Y. (2016). UV technology for use in textile dyeing and printing: Photocured applications. Dyes and Pigments, 134, 442–447.

Baig, R., Hussain, D., Najam-Ul-Haq, M., et al. (2019). Eco-friendly route for dyeing of cotton fabric using three organic mordants in reactive dyes. Industria Textila, 70(1), 25–29.

Bairabathina, V., Shanmugam, K. S., & Chilukoti, G. R. (2022). A review on reverse micellar approach for natural fiber dyeing. Coloration Technology, 138(4), 329–341.

Benkhaya, S., M’rabet, S., Lgaz, H., El Bachiri, A., & El Harfi, A. (2022). Dyes: Classification, pollution, and environmental effects. In Dye biodegradation, mechanisms and techniques: Recent advances (pp. 1–50). Springer.

Bhuiyan, M. A., Shahid, M. A., Hannan, M. A., & Kafi, M. A. (2012). Influence of mixed alkali on fixation of deep shade on single Jersey cotton fabrics with reactive dyes. Journal of Chemical Engineering, 27, 58–63.

Bukhari, M. N., Shabbir, M., Rather, L. J., et al. (2017). Dyeing studies and fastness properties of brown naphtoquinone colorant extracted from Juglans regia L on natural protein fiber using different metal salt mordants. Textiles and Clothing Sustainability, 3, 1–9.

Cai, G., Sun, L., Wu, J., & Wang, J. (2015). Influence of nonionic surfactant on hydrolysis of vinyl sulfone reactive dye. Journal of Surfactants and Detergents, 18(6), 1127–1135.

Choi, T. S., Shimizu, Y., Shirai, H., & Hamada, K. (2001). Disperse dyeing of polyester fiber using gemini surfactants containing ammonium cations as auxiliaries. Dyes and Pigments, 50(1), 55–65.

David, S. K., & Pailthorpe, M. T. (1999). Classification of textile fibres: Production, structure, and properties. In Forensic examination of fibres (p. 2). Ellis Horwood.

El Harfi, S., & El Harfi, A. (2017). Classifications, properties and applications of textile dyes: A review. Applied Journal of Environmental Engineering Science, 3(3), 00000-3.

Elsahida K, Fauzi A M, Sailah I, & Siregar I Z (2019, December) Sustainability of the use of natural dyes in the textile industry. In IOP Conference Series: Earth and Environmental Science (Vol. 399, No. 1, p. 012065). IOP Publishing.

Fox, M. R. (1973). Fixation processes in dyeing. Review of Progress in Coloration and Related Topics, 4(1), 18–37.

Goswami, P., Blackburn, R. S., Taylor, J., & White, P. (2009). Dyeing behaviour of lyocell fabric: Effect of NaOH pre-treatment. Cellulose, 16, 481–489.

Grishanov, S. (2011). Structure and properties of textile materials. In Handbook of textile and industrial dyeing (pp. 28–63). Woodhead Publishing.

Gupta, B. S. (2008). Textile fiber morphology, structure and properties in relation to friction. In Friction in textile materials (pp. 3–36). Woodhead Publishing.

Haji, A., & Naebe, M. (2020). Cleaner dyeing of textiles using plasma treatment and natural dyes: A review. Journal of Cleaner Production, 265, 121866.

Hosen, M. D., Rabbi, M. F., Raihan, M. A., & Al Mamun, M. A. (2021). Effect of turmeric dye and biomordants on knitted cotton fabric coloration: A promising alternative to metallic mordanting. Cleaner Engineering and Technology, 3, 100124.

Hossain, M. Y., Sarker, S., & Zakaria, M. (2020). Influence of process parameters on exhaustion, fixation and color strength in dyeing of cellulose fiber with reactive dye. International Journal of Textile Science, 3(127), 2690–0106.

Hynes, N. R., Kumar, J. S., Kamyab, H., et al. (2020). Modern enabling techniques and adsorbents based dye removal with sustainability concerns in textile industrial sector – A comprehensive review. Journal of Cleaner Production, 272, 122636.

Iqbal, J., Bhatti, I. A., & Adeel, S. (2008). Effect of UV radiation on dyeing of cotton fabric with extracts of henna leaves. Indian Journal of Fibre & Textile Research, 33, 157–162.

Ismal, Ö. (2016). Patterns from nature: Contact printing. Journal of Textile Association, 77(2), 81–91.

İşmal, Ö. E., & Yıldırım, L. (2019). Metal mordants and biomordants. In The impact and prospects of green chemistry for textile technology (pp. 57–82). Woodhead Publishing.

Jabar, J. M., Ogunmokun, A. I., & Taleat, T. A. (2020). Color and fastness properties of mordanted Bridelia ferruginea B dyed cellulosic fabric. Fashion and Textiles, 7, 1–3.

Jun, J. H., Sawada, K., & Ueda, M. (2004). Application of perfluoropolyether reverse micelles in supercritical CO2 to dyeing process. Dyes and Pigments, 61(1), 17–22.

Kamel, M. M., El-Shishtawy, R. M., Hanna, H. L., & Ahmed, N. S. (2003). Ultrasonic-assisted dyeing: I. Nylon dyeability with reactive dyes. Polymer International, 52(3), 373–380.

Kan, C. W. (2018). Non-aqueous wool fiber dyeing process using reverse micellar approach. In 11th Annual TechConnect World Innovation Conference and Expo: Held Jointly with the 20th Annual Nanotech Conference and Expo, the 2018 SBIR/STTR Spring Innovation Conference, and the Defense TechConnect DTC Spring Conference 2018, TechConnect, pp. 249–252.

Ketema, A., & Worku, A. (2020). Review on intermolecular forces between dyes used for polyester dyeing and polyester fiber. Journal of Chemistry, 2020, 1–7.

Kirk-Othmer. (2004). Kirk-Othmer encyclopedia of chemical technology (p. 7). Wiley.

Kozlowski, R. M., & Mackiewicz-Talarczyk, M. (Eds.). (2020). Handbook of natural fibres: Volume 1: Types, properties and factors affecting breeding and cultivation. Woodhead Publishing.

Lewis, D. M. (2014). Developments in the chemistry of reactive dyes and their application processes. Coloration Technology, 130(6), 382–412.

Lewis, D. M., & Ho, Y. C. (1995). Improved fixation of dyes on polyamide fibres. Part 1: Using 1, 3, 5-triacroylamino-hexahydro-s-triazine as a crosslinking agent. Dyes and Pigments, 28(3), 171–192.

Lewis, D. M., & Vo, L. T. (2007). Dyeing cotton with reactive dyes under neutral conditions. Coloration Technology, 123(5), 306–311.

Lützel, G. (1966). Dye fixation by means of polyfunctional cross–linking agents. Journal of the Society of Dyers and Colourists, 82(8), 293–299.

Merdan, N., Akalin, M., Kocak, D., & Usta, I. (2004). Effects of ultrasonic energy on dyeing of polyamide (microfibre)/Lycra blends. Ultrasonics, 42(1–9), 165–168.

Millington, K. (1998). Using ultraviolet radiation to reduce pilling of knitted wool and cotton. Textile Research Journal, 68(6), 413–421.

Millington, K. R. (2006). UV technology: Applications in the textile industry. Journal of Textile Fibre Technology, 1–4.

Miran, M. S., Manjum, M., Islam, M. M., et al. (2015). Micelle-assisted dyeing of cotton with reactive dyes. In Textile research conference 2015, Dhaka, Bangladesh.

Niemeyer, E. D., & Bright, F. V. (1998). The pH within PFPE reverse micelles formed in supercritical CO2. Journal of Physical Chemistry B, 102(8), 1474–1478.

Oakes, J., & Gratton, P. (2003). Solubilisation of dyes by surfactant micelles. Part 2; Molecular interactions of azo dyes with cationic and zwitterionic surfactants. Coloration Technology, 119(2), 100–107.

Patel, H. (2018). Charcoal as an adsorbent for textile wastewater treatment. Separation Science and Technology, 53(17), 2797–2812.

Paul, D., Das, S. C., Islam, T., et al. (2017). Effect of alkali concentration on dyeing cotton knitted fabrics with reactive dyes. Journal of Chemistry, 11, 162–167.

Prabu, H. G., & Sundrarajan, M. (2002). Effect of the bio-salt trisodium citrate in the dyeing of cotton. Coloration Technology, 118(3), 131–134.

Sawada, K., & Ueda, M. (2003a). Adsorption and fixation of a reactive dye on cotton in non-aqueous systems. Coloration Technology, 119(3), 182–186.

Sawada, K., & Ueda, M. (2003b). Dyeing of protein fiber in a reverse micellar system. Dyes and Pigments, 58(2), 99–103.

Sawada, K., Takagi, T., Jun, J. H., et al. (2002). Dyeing natural fibres in supercritical carbon dioxide using a nonionic surfactant reverse micellar system. Coloration Technology, 118(5), 233–237.

Saxena, S., & Raja, A. S. (2014). Natural dyes: Sources, chemistry, application and sustainability issues. In Roadmap to sustainable textiles and clothing: Eco-friendly raw materials, technologies, and processing methods (pp. 37–80). Springer.

Scalbi, S., Tarantini, M., & Mattioli, D. (2005). Efficient use of water in the textile finishing industry (pp. 1–18). E-Water (electronic publication of the European Water Association).

Singh, G., Mathur, P., Singh, N., & Sheikh, J. (2019). Functionalization of wool fabric using kapok flower and bio-mordant. Sustainable Chemistry and Pharmacy, 14, 100184.

Sun, D., Guo, Q., & Liu, X. (2010). Investigation into dyeing acceleration efficiency of ultrasound energy. Ultrasonics, 50(4–5), 441–446.

Sun, D., Zhang, X., & Du, H. (2017). Application of liquid organic salt to cotton dyeing process with reactive dyes. Fibers and Polymers, 18, 1969–1974.

Tang, B., Zhang, S., Yang, J., & Liu, F. (2006). Synthesis of a novel water-soluble crosslinking polymeric dye with good dyeing properties. Dyes and Pigments, 68(1), 69–73.

Tang, A. Y. L., Lee, C. H., Wang, Y., & Kan, C. W. (2018). Dyeing properties of cotton with reactive dye in nonane nonaqueous reverse micelle system. ACS Omega, 3(3), 2812–2819.

Wang, Y., Lee, C. H., Tang, Y. L., & Kan, C. W. (2016). Dyeing cotton in alkane solvent using polyethylene glycol-based reverse micelle as reactive dye carrier. Cellulose, 23, 965–980.

Wolela, A. D. (2021). Effect and role of salt in cellulosic fabric dyeing. Advance Research in Textile Engineering, 6(1), 1061.

Xie, K., Cheng, F., Zhao, W., & Xu, L. (2011). Micelle dyeing with low liquor ratio for reactive dyes using dialkyl maleic acid ester surfactants. Journal of Cleaner Production, 19(4), 332–336.

Yen, M. S. (2001). Application of chitosan/nonionic surfactant mixture in reactive dyes for dyeing wool fabrics. Journal of Applied Polymer Science, 80(14), 2859–2864.

Zhang, H. Y. (2014). Application of K/S value in determination of fixation rate. In Advanced materials research (Vol. 1048, pp. 116–119). Trans Tech Publications Ltd.

Zhang, S., Tang, B., Yang, J., et al. (2000). Crosslinking dyes. Kirk-Othmer Encyclopedia of Chemical Technology, 4, 1–45.

Zhang, S., Ma, W., Tang, B., & Shan, B. (2022). Innovation and application of dyes with high fixation. Chinese Journal of Chemical Engineering, 51, 146–152.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Chowdhury, U.S., Rahman, F., Ehsan, M.F., Pabel, M.Y., Islam, M.M. (2024). Catalytic Methods for Sustainable Textile Dyeing. In: Muthu, S.S. (eds) Sustainable Manufacturing Practices in the Textiles and Fashion Sector. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry. Springer, Cham. https://doi.org/10.1007/978-3-031-51362-6_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-51362-6_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-51361-9

Online ISBN: 978-3-031-51362-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)