Abstract

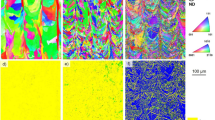

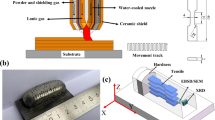

Six pre-alloyed high entropy alloys powders from the CoCrFeNiMnzAlxCuy family were used to manufacture samples through Laser Powder Bed Fusion technology. These samples were used to assess the manufacturability, microstructure and mechanical properties of the developed alloys. It was found that increasing the Al concentration promoted the formation of a BCC/B2 phase, increasing the hardness and having a direct positive impact on the tensile properties. However, adding more aluminium than what can be found in the Al0.5CoCrFeNi alloy led to extensive manufacturability issues that hindered the tensile properties. On the other hand, the Cu concentration did not appear to yield any significant impact on the microstructures and mechanical properties of the alloys. The considered additively manufactured alloys presented an overall higher hardness than their conventionally manufactured counterparts, but a lower ductility. Thermal treatment led to the precipitation of a σ phase in Al-containing HEAs, and of a secondary FCC phase in Cu-containing alloys. Finally, this paper proves the potential of the CoCrFeNiAlx alloy family compared to single-phase stainless steels such as 316L and two-phase stainless steels such as SAF 2507.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhang, Y., et al.: Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014). https://doi.org/10.1016/j.pmatsci.2013.10.001

Cantor, B., Chang, I.T.H., Knight, P., Vincent, A.J.B.: Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377, 213–218 (2004). https://doi.org/10.1016/j.msea.2003.10.257

Zhang, Y., Yang, X., Liaw, P.K.: Alloy design and properties optimization of high-entropy alloys. JOM 64, 830–838 (2012). https://doi.org/10.1007/s11837-012-0366-5

Ye, Y.F., Wang, Q., Lu, J., Liu, C.T., Yang, Y.: High-entropy alloy: challenges and prospects. Mat. Today 19, 349–362 (2016). https://doi.org/10.1016/j.mattod.2015.11.026

Shams, S.A.A., et al.: Low-cycle fatigue properties of CoCrFeMnNi high-entropy alloy compared with its conventional counterparts. Mater. Sci. Eng. A 792, 139661 (2020). https://doi.org/10.1016/j.msea.2020.139661

Bartolomeu, F., et al.: 316L stainless steel mechanical and tribological behavior—A comparison between selective laser melting, hot pressing and conventional casting. Addit. Manuf.. Manuf. 16, 81–89 (2017). https://doi.org/10.1016/j.addma.2017.05.007

Xian, X., et al.: Precipitation and its strengthening of Cu-rich phase in CrMnFeCoNiCux high-entropy alloys. Mat. Sci. Eng. A 713, 134–140 (2018). https://doi.org/10.1016/j.msea.2017.12.060

Zhu, Z.G., et al.: Hierarchical microstructure and strengthening mechanisms of a CoCrFeNiMn high entropy alloy additively manufactured by selective laser melting. Scripta Mater. 154, 20–24 (2018). https://doi.org/10.1016/j.scriptamat.2018.05.015

Zhou, P.F., Xiao, D.H., Wu, Z., Ou, X.Q.: Al0.5FeCoCrNi high entropy alloy prepared by selective laser melting with gas-atomized pre-alloy powders. Mater. Sci. Eng. A 739, 86–89 (2019). https://doi.org/10.1016/j.msea.2018.10.035

Karlsson, D., et al.: Elemental segregation in an AlCoCrFeNi high-entropy alloy – a comparison between selective laser melting and induction melting. J. Alloy. Compd. 784, 195–203 (2019). https://doi.org/10.1016/j.jallcom.2018.12.267

Gao, J., et al.: Fabricating antibacterial CoCrCuFeNi high-entropy alloy via selective laser melting and in-situ alloying. J. Mater. Sci. Technol. 102, 159–165 (2022). https://doi.org/10.1016/j.jmst.2021.07.002

Lee, C., et al.: Lattice distortion in a strong and ductile refractory high-entropy alloy. Acta Mater. 160, 158–172 (2018). https://doi.org/10.1016/j.actamat.2018.08.053

Callister, Jr.: WD Fundamentals of Materials Science and Engineering, 5th edn. John Wiley & Sons, Inc.

Wang, W.-R., Wang, W.-L., Wang, S.-C., Tsai, Y.-C., Lai, C.-H., Yeh, J.-W.: Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Interm. 26, 44–51 (2012). https://doi.org/10.1016/j.intermet.2012.03.005

Du, C., Hu, L., Pan, Q., Chen, K., Zhou, P., Wang, G.: Effect of Cu on the strengthening and embrittling of an FeCoNiCr-xCu HEA. Mater. Sci. Eng. AA 832, 142413 (2022). https://doi.org/10.1016/j.msea.2021.142413

Acknowledgements

This work is supported by the French Defense Innovation agency (AID) from the French Army Ministry. The authors also gratefully acknowledge the helpful comments and suggestions of the reviewers, which have improved the presentation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Barth, E., Hor, A. (2024). Manufacturability of CoCrFeNiMnzAlxCuy High Entropy Alloy by Laser Powder Bed Fusion. In: Mabrouki, T., Sahlaoui, H., Sallem, H., Ghanem, F., Benyahya, N. (eds) Advances in Additive Manufacturing: Materials, Processes and Applications. AIAM 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-47784-3_3

Download citation

DOI: https://doi.org/10.1007/978-3-031-47784-3_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-47783-6

Online ISBN: 978-3-031-47784-3

eBook Packages: EngineeringEngineering (R0)