Abstract

The ability of manufacturing companies to compete depends strongly on the efficient use of production resources and the flexibility to adapt to changing production conditions. Essential requirements for the energetic infrastructure (EGI) result from the production itself, e.g., security of supply, efficiency and peak shaving. Since production always takes priority and must not be disturbed, the flexibility potential in terms of energy efficiency lies primarily in the EGI. Based on this, strategies will be developed that support companies in increasing their efficiency and flexibility by optimizing the configuration and operation of the EGI, while production processes are reliably supplied and not adapted. This is reached with intelligent operation strategies for the heating and cooling network based on forecasts, the use of energy storage systems, and the coupling of energy sectors. This paper presents an approach for energy forecasts used for the optimization of operation strategies. Hence, an energy-forecast-tool was developed, which is used for the prediction of electrical and thermal loads depending on the expected production. Therefore, machine learning models are trained with past weather, energy, and production data. Using production planning data and weather forecasts, the model can predict energy demands as input for an EGI optimization.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The exhaustion of fossil energy sources, increased use of renewable energy, restrictions due to government regulations or international interstate crises and conflicts, lead to higher energy prices and a weakening of confidence and financial markets [4, 10, 16]. In addition, as renewable energy is expanding and a generation-based consumption is increasing due to volatility of renewable energies, industry is increasingly forced to flexibly adapt to energy supply [17, 18]. This change ensures a shift of the manufacturing industry towards more efficient and sustainable systems, thus requiring the identification of energy saving opportunities and the development of new strategies to improve the energy efficiency of industrial energy systems [4].

Since manufacturing companies are often under enormous competitive pressure and are forced to constantly optimize their production with regard to costs, quality and time, interventions in the ongoing production process are associated with effort and involve risks with regard to these three mentioned central factors of project management [18]. For this reason, the guiding principle in many areas is not to affect production. This leaves the energy infrastructure for providing the energy requirements (in the form of electricity, heating, cooling) of production as the only adjusting factor for energy saving potentials. This flexibilization of the energetic infrastructure (EGI) is being investigated in more detail in the ProEnergie Bayern research project [13] in order to derive operating strategies for the EGI using AI-based energy forecasts. These forecasts use production planning data and weather forecasts to predict load curves for the electricity, heating and cooling sectors. They can be used to generate an operating strategy for the EGI components in order, for example, to charge or discharge storage facilities in an optimized manner, to run energy plants at the optimal operating point and to reduce load peaks [9, 12].

2 Related Work

In this paper, the focus is on the prediction of energetic load curves of the production. In recent years, a large number of different prediction methods have been investigated. For example, significant benefits can be achieved by using simulations to predict energy demand. Due to the effort required for simulations, it can be more feasible for an SME to use energy measurements and numerical approaches to identify potential energy savings or efficiency improvements [7]. Therefore, an alternative to simulations are AI methods and thus machine learning (ML). For example, Artificial Neural Networks (ANN) [11] are well suited for energy consumption modeling [1, 8, 19]. Usually, an ANN is trained during the model development phase using experimental or previous operational data [14]. Among others, the focus for ML predictions in recent years has often been on energy predictions for buildings [3, 6, 20] or whole district heating systems, where the usual load forecasts are based on decision trees or simple neural networks [2, 5].

For industrial energy demand, there is a wide range of techniques for modeling and forecasting. Reinhardt et al. understand energy consumption forecasting as a modeling problem and therefore derive their classification scheme from the input-processing-output cycle of model development. The distinguished categories are system (consisting of the dimensions factory, multiple machines, single machine, and machine part), input (consisting of the dimensions energy, environment, process, and product), and processing (consisting of the dimensions artificial neural network, fuzzy logic, empirical expression, simulation, and theoretical expression) [14].

Schmidt et al. suggest a methodology for the reliable prediction of specific energy consumption of arbitrary manufacturing processes. This methodology is based on a few energy measurements and requires little effort and previous knowledge due to precise specifications about the machines. Firstly, a decision tree is provided to categorize production machines into groups according to their energy consumption. Then for each machine group, an individual procedure is presented for establishing a prediction model. For this purpose, the energy consumption is either estimated with an average value or broken down into repeatable energy consumption components. For the complex machines, the energy consumption in manufacturing can be estimated using nominal power, exergy, simulation and empirical modeling [15].

3 Concept

In the solution proposed the adaption and optimization of the configuration and operation of the EGI is reached through intelligent operation strategies, the use of electrical and thermal energy storage systems and the coupling of energy sectors. Therefore, energy forecasts are developed and used for the optimization of the strategies and the configuration of the EGI. To increase the accuracy of the forecasts, ML models are trained with past weather, energy and production data (historical data). As a result, these models can be used to forecast energy demands on factory, machine group or machine level on basis of production planning data and weather forecasts (planning data). Two software tools were developed for this approach: the energy-forecast-tool to predict the electrical and thermal loads depending on the expected production and the EGI-optimization-tool to optimize the EGI’s components and operational strategy.

As shown in Fig. 1, historical data from three different sources is used for the model training in the energy-forecast-tool:

-

i)

production data: information about the processes (e.g. start and end time, duration), product and plant specific information (e.g. material, geometry, process id, number of produced parts), the shift schedule and the work center calendar.

-

ii)

energy demands: the electrical and thermal load profiles for the corresponding plant, section or factory.

-

iii)

weather data: temperature and humidity of the weather station of the factory or the nearest station of the German Metereologial Service (“Deutscher Wetterdienst”, DWD).

Since the historical data was acquired from multiple different sources and was therefore not necessarily synchronized, the data needed to be harmonized in regard to a defined time interval. In this tool, a one-minute-interval was defined. For the training of the ML models, a time series was generated with a moving window. The size of the window depends on the use case and was set in the range between 60 min and 10 h. Each window corresponds with one data point of the energy demand data set. The data was then split into a train and test set, with a ratio of 75:25. The train set was used to train the models, and the test set to evaluate the models and to select the best trained model for further predictions. As shown in Table 1, multiple model architectures were trained and evaluated with varying hyperparameters in a defined range.

The evaluation of the models is based on selected metrics, e.g. mean absolute error (MAE), root mean square error (RMSE) and coefficient of determination (R\(^{2}\)). Afterwards, the best trained model can be used to predict energy loads based on production planning data and weather forecasts (planning data). Therefore, the data has to go through the same steps of preprocessing as described for the historical data. The predictions can be exported from this energy-forecast-tool for further use in the EGI-optimization-tool. The forecasting enables the optimization of the operating strategies of the energetic infrastructure. For example, with the knowledge of upcoming electrical energy demands, the charging and discharging of electrical storage systems can be adjusted flexible to avoid load peaks and to purchase energy economically. In addition, power plants can be operated at their optimum efficiency level.

The EGI-optimization-tool was developed to simulate the industrial energy system based on models of the energy consumers, producers and storage systems. These models were mainly developed as grey-box models to reduce computing times and to increase the generalization and transferability for similiar components. In the tool, the infrastructure was recreated with components that include different models and operating strategies that describe the functionality and purpose of the component within the EGI. The operating strategies include three types: reduction of peak loads, optimization of self-sufficiency for energy and increase in energy efficiency (e.g. optimal operating points). The energy demands are representated by historical load profiles or by the predicted energy loads from the energy-forecast-tool. The parameters of the energy producers and storage systems are being defined in entry forms of the tool. Afterwards, optimized operating strategies for the EGI components are simulated to increase the energy efficiency and flexibility of the EGI.

4 Experimental Evaluation

The concept of the energy-forecast-tool was evaluated on a use case at a manufacturing company in the metal processing industry. The research subject were two laser cutting machines. The aim was to predict the electrical load based on the production data. Therefore, the data was collected for six months and included the start and end date of the orders, the duration, the material number and thickness and the state of the machine, together with the shift schedule and the work site calendar. The electrical load was captured in 15 min intervals as an average for the elapsed period. Since these two datasets were not synchronous, the production data was transformed to a uniform time interval of one minute. Intervals where no order was produced were zero-filled. The 15 min intervals of the electrical load were then assigned to the corresponding 15 one minute intervals of the transformed production data.

The data was then split into a train, validation and test set (ratio of 65:10:25) without shuffling, so that the periods of the sets are consecutive in the mentioned order. The models were then trained on the train set and the hyperparameters were optimized on the validation set for each architecture. For the training of the models, the Adam algorithm was used as optimizer and the mean square error (MSE) was used as the loss function. Afterwards, the best trained models regarding the validation set were evaluated on the test data. As shown in Table 2, the best results over all metrics were achieved with the model with GRU layers.

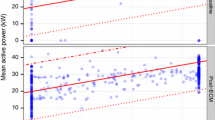

Figure 2 shows the load predicted with the GRU model compared with the actual load over an one week period of the test data. A qualitative analysis of the prediction has indicated that the model was able to approximate the energy demand of the machine and to predict most of the load peaks. However, there were slight deviations observed, especially at the upper and lower limits.

5 Discussion and Future Work

The EGI-optimization-tool is used to investigate and optimize changes and extensions to the energy building infrastructure. The EGI can be configured dynamically. For example, the integration of generation plants and storage units can be examined. The optimization currently takes place via a so-called job list with multiple parameter sets. In the future, it will also be possible to integrate mathematical parameter optimization.

The energy-forecast-tool is used to predict the electrical and thermal loads depending on the expected production. The quality of the predictions strongly depends on the input, especially how accurate the planning data is. The production processes are not adapted or optimized, in that way, the tool does not disturb the production itself.

With our methodology, we were able to show that the energy demand can be predicted with ANNs on basis of production data. The best result was achieved with the GRU model, whereby the quality of the models depend on the amount of training data and thus could be further improved with data over a longer period.

AutoML approaches are intended to further reduce the user effort required to optimize the ML models. AutoML eliminates most of the manual steps of the classical iterative process (preparation of data, feature engineering, selection of the appropriate ML models and features, training of the models - incl. hyperparameter search, prediction by the model). Thus, the user only has to define the prepared training data as input and an optimized model is created automatically.

In addition, the approach of further developing the ML models with more and more data will be pursued in the future. Transfer learning will also be used to reduce the training effort and make it transferable for similar processes. Additionally, federated learning can be used here to optimize ML models across company boundaries.

References

Ak, R., Helu, M.M., Rachuri, S.: Ensemble neural network model for predicting the energy consumption of a milling machine. In: 20th Design for Manufacturing and the Life Cycle Conference; 9th International Conference on Micro- and Nanosystems, vol. 4, p. V004T05A056. American Society of Mechanical Engineers, Boston (2015)

Beckmann, M., Hurtado, A., Technische Universität Dresden hrsg: Kraftwerkstechnik 2019: Power plant technology - Optimierte Wärmelastprognose mittels Deep Learning, p. 425. SAXONIA, Freiberg (2019)

Dagdougui, H., Bagheri, F., Le, H., Dessaint, L.: Neural network model for short-term and very-short-term load forecasting in district buildings. Energy Build. 203, 109408 (2019). https://doi.org/10.1016/j.enbuild.2019.109408

Diaz C., J.L., Ocampo-Martinez, C.: Energy efficiency in discrete-manufacturing systems: insights, trends, and control strategies. J. Manuf. Syst. 52, 131–145 (2019). https://doi.org/10.1016/j.jmsy.2019.05.002

Faber, T., Finkenrath, M.: Load forecasting in district heating systems using stacked ensembles of machine learning algorithms. In: Gehalten auf der 14th International Renewable Energy Storage Conference 2020 (IRES 2020), Bonn, Germany (2021)

Fumo, N.: A review on the basics of building energy estimation. Renew. Sustain. Energy Rev. 31, 53–60 (2014). https://doi.org/10.1016/j.rser.2013.11.040

Garwood, T.L., Hughes, B.R., Oates, M.R., O’Connor, D., Hughes, R.: A review of energy simulation tools for the manufacturing sector. Renew. Sustain. Energy Rev. 81, 895–911 (2018). https://doi.org/10.1016/j.rser.2017.08.063

Kant, G., Sangwan, K.S.: Predictive modeling for power consumption in machining using artificial intelligence techniques. Procedia CIRP 26, 403–407 (2015). https://doi.org/10.1016/j.procir.2014.07.072

Lange, C., Rueß, A., Nuß, A., Öchsner, R., März, M.: Dimensioning battery energy storage systems for peak shaving based on a real-time control algorithm. Appl. Energy 280, 115993 (2020). https://doi.org/10.1016/j.apenergy.2020.115993

Liadze, I., Macchiarelli, C., Mortimer-Lee, P., Juanino, P.S.: The Economic Costs of the Russia- Ukraine Conflict, 12 (2022)

Lu, Z., Pu, H., Wang, F., Hu, Z., Wang, L.: The expressive power of neural networks: a view from the width. In: Guyon, I., et al. (hrsg.) Advances in Neural Information Processing Systems. Curran Associates, Inc. (2017)

Öchsner, R., Nuß, A., Lange, C., Rueß, A.: Research platform: decentralized energy system for sector coupling. Chem. Eng. Technol. 42, 1886–1894 (2019). https://doi.org/10.1002/ceat.201800714

ProEnergie - Bayern. https://www.proenergie-bayern.de/

Reinhardt, H., Bergmann, J.-P., Münnich, M., Rein, D., Putz, M.: A survey on modeling and forecasting the energy consumption in discrete manufacturing. Procedia CIRP 90, 443–448 (2020). https://doi.org/10.1016/j.procir.2020.01.078

Schmidt, C., Li, W., Thiede, S., Kara, S., Herrmann, C.: A methodology for customized prediction of energy consumption in manufacturing industries. Int. J. Precis. Eng. Manuf. Green Technol. 2(2), 163–172 (2015). https://doi.org/10.1007/s40684-015-0021-z

Schuh, G., et al.: Datenbedarfe für eine energie-flexible Produktionsplanung und -steuerung. Zeitschrift für wirtschaftlichen Fabrikbetrieb. 113, 550–553 (2018). https://doi.org/10.3139/104.111966

Walther, J., Weigold, M.: A systematic review on predicting and forecasting the electrical energy consumption in the manufacturing industry. Energies 14, 968 (2021). https://doi.org/10.3390/en14040968

Weckmann, S., Jin, H., Sauer, A.: Demand side management - evaluation of DSM potential, based on the energy value stream. wt. 106, 462–468 (2016). https://doi.org/10.37544/1436-4980-2016-06-92

Zhao, G., Hou, C., Qiao, J., Cheng, X.: Energy consumption characteristics evaluation method in turning. Adv. Mech. Eng. 8, 168781401668073 (2016). https://doi.org/10.1177/1687814016680737

Zhao, H., Magoulès, F.: A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 16, 3586–3592 (2012). https://doi.org/10.1016/j.rser.2012.02.049

Acknowledgement

This contribution was supported by the Bavarian Research Foundation as part of the research project “ProEnergie”.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Trenz, A., Hoffmann, C., Lange, C., Öchsner, R. (2023). Increasing Energy Efficiency and Flexibility by Forecasting Production Energy Demand Based on Machine Learning. In: Kohl, H., Seliger, G., Dietrich, F. (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28839-5_50

Download citation

DOI: https://doi.org/10.1007/978-3-031-28839-5_50

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28838-8

Online ISBN: 978-3-031-28839-5

eBook Packages: EngineeringEngineering (R0)