Abstract

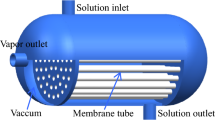

One of the possible options for renewable energy is the use of bioethanol biofuels. To concentrate bioethanol, it is effective to use the process of vacuum membrane distillation. Membrane process is a relatively new and one of the most effective ways to separate multicomponent mixtures. Membrane distillation has many features compared to traditional separation methods, such as: low operating temperature of the process; the solution to be separated must not be heated to boiling point. A mathematical model of the process of vacuum membrane distillation is proposed and investigated. A control system has been developed using the method of analysis and synthesis of predictive control model (MPC) control systems based on mathematical optimization methods using predictive models. The method is chosen because the membrane changes its properties over time and can provide better control of the process over a long period of time. The systems of automatic control of a non-stationary dynamic object based on the MPC controller and the PID controller with fuzzy logic are compared.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Burban, A.F.: Membrane distillation in the processes of water treatment, desalination and wastewater treatment. Sci. Notes 157, 15–24 (2014)

Drioli, E., Romano, M.: Progress and new perspectives on integrated membrane operations for sustainable industrial growth. Ind. Eng. Chem. Res. 40, 1277–1300 (2001)

Bryk, M.T., Nigmatullin, R.R.: Membrane distillation. Adv. Chem. 12(63), 1114–1129 (1994)

Alkhudhiri, A., Darwish, N., Hilal, N.: Membrane distillation: a comprehensive review. Desalination 287, 3–18 (2012)

Khayet, M.: Membranes and theoretical modeling of membrane distillation: a review. Adv. Coll. Interface. Sci. 164, 56–88 (2011)

Ugrozov, V.V.: Mathematical modeling of the process of contact membrane distillation in a flow-through module. TOCT 28(4), 375–380 (1994)

Benavides-Prada, O.A., Guevara-Lastre, C.A., Barón-Núñez, F.W.: Vacuum membrane distillation: modeling and analysis for recovery of ethanol from ethanol/water solutions. J. Oil Gas Energy 5(2), 47–57 (2013)

Ladieva, L.R., Zhulinsky, O.A.: Mathematical model of the process of contact membrane distillation. Autom. Autom. Electrotech. Complexes Syst. 2(14), 46–51 (2004)

Ladieva, L.R., Zhulinsky, O.A.: Mathematical model of the dynamics of the contact membrane distillation process. Autom. Prod. Process. 1(20), 19–21 (2005)

Ladieva, L.R., Onishchenko, V.O., Dubik, R.M.: Mathematical modeling of temperature distribution in the membrane module in the process of membrane distillation. Sci.-intensive Technol. 1(25), 5–8 (2015)

Ladieva, L.R., Dubik, R.M.: Mathematical model of heat exchange in the process of contact membrane distillation. Energy Econ. Technol. Ecol. 1(28), 10–16 (2011)

Ladieva, L.R., Bereza, O.M.: Patent for utility model 144730. Method for automatic control of membrane distillation process. Bull. 20 (2020). Declared 12 March 2020, Published 26 October 2020

Ladieva, L.R., Bereza, O.M.: Mathematical modeling of vacuum membrane distillation process in ethanol production. Sci.-intensive Technol. 1(49), 77–82 (2021). https://doi.org/10.18372/2310-5461.49.15293

Denisenko, N.A., Rogachev, A.I.: The problem of optimal control with prediction for a quadratic functional. Bull. Vinnytsia Polytechnic Inst. 6, 10–13 (2006)

Veremey, E.I., Eremeev, V.V.: Introduction to management problems based on predictions. All-Russian scientific conference “Design of scientific and engineering applications in the MATLAB environment”, pp. 98–115 (2004)

Goryunov, A.G., Nadezhdin, I.S., Manenti, F.: Control systems for a nonstationary object based on an MPC controller and a PID controller with fuzzy logic. Manag. Large Syst. Anal. Synthesis Control Syst. 75, 50–75 (2018)

Korniyenko, B., Ladieva, L.: Method of static optimization of the process of granulation of mineral fertilizers in the fluidized bed. In: Hu, Z., Petoukhov, S., Dychka, I., He, M. (eds.) ICCSEEA 2021. LNDECT, vol. 83, pp. 196–207. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-80472-5_17

Zhulynskyi, A.A., Ladieva, L.R., Korniyenko, B.Y.: Parametric identification of the process of contact membrane distillation. ARPN J. Eng. Appl. Sci. 14(17), 3108–3112 (2019)

Galata, L., Korniyenko, B.: Research of the training ground for the protection of critical information resources by iRisk method. In: Zawiślak, S., Rysiński, J. (eds.) Engineer of the XXI Century. MMS, vol. 70, pp. 227–237. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-13321-4_21

Korniyenko, B.Y., Borzenkova, S.V., Ladieva, L.R.: Research of three-phase mathematical model of dehydration and granulation process in the fluidized bed. ARPN J. Eng. Appl. Sci. 14(12), 2329–2332 (2019)

Kornienko, Y.M., Liubeka, A.M., Sachok, R.V., Korniyenko, B.Y.: Modeling of heat exchangement in fluidized bed with mechanical liquid distribution. ARPN J. Eng. Appl. Sci. 14(12), 2203–2210 (2019)

Korniyenko, B., Galata, L., Ladieva, L.: Security estimation of the simulation polygon for the protection of critical information resources. Paper Presented at the CEUR Workshop Proceedings, vol. 2318, pp. 176–-187 (2018)

Galata, L.P., Korniyenko, B.Y., Yudin, A.K.: Research of the simulation polygon for the protection of critical information resources. Paper Presented at the CEUR Workshop Proceedings, vol. 2067, pp. 23–31 (2017)

Korniyenko, B., Osipa, L.: Identification of the granulation process in the fluidized bed. ARPN J. Eng. Appl. Sci. 13(14), 4365–4370 (2018)

Korniyenko, B., Galata, L.: Implementation of the information resources protection based on the CentOS operating system. In: 2019 IEEE 2nd Ukraine Conference on Electrical and Computer Engineering, UKRCON 2019 – Proceedings 2019, pp. 1007–1011 (2019)

Zhuchenko, A.I., Cheropkin, Y.S., Osipa, R.A., Korniyenko, B.Y.: Features of mathematical modeling of the first stage of paper web drying. ARPN J. Eng. Appl. Sci. 15(5), 647–656 (2020)

Kornienko, Y.M., Haidai, S.S., Sachok, R.V., Liubeka, A.M., Korniyenko, B.Y.: Increasing of the heat and mass transfer processes efficiency with the application of non-uniform fluidization. ARPN J. Eng. Appl. Sci. 15(7), 890–900 (2020)

Korniyenko, B., Galata, L., Ladieva, L.: Research of information protection system of corporate network based on GNS3. In: 2019 IEEE International Conference on Advanced Trends in Information Theory, ATIT 2019 – Proceedings 2019, pp. 244–248 (2019)

Korniyenko, B., Galata, L., Ladieva, L.: Mathematical model of threats resistance in the critical information resources protection system. Paper Presented at the CEUR Workshop Proceedings, vol. 2577, pp. 281–291 (2019)

Korniyenko, B., Ladieva, L.: Mathematical modeling dynamics of the process dehydration and granulation in the fluidized bed. In: Hu, Z., Petoukhov, S., Dychka, I., He, M. (eds.) ICCSEEA 2020. AISC, vol. 1247, pp. 18–30. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-55506-1_2

Zhuchenko, A.I., Yaroshchuk, L.D., Chechet, A.M., Makarov, T.V., Korniyenko, B.Y.: Position of the sustainable development in the system of soda production automation. ARPN J. Eng. Appl. Sci. 16(2), 255–269 (2021)

Korniyenko, B., Ladieva, L., Galata, L.: Control system for the production of mineral fertilizers in a granulator with a fluidized bed. In: Proceedings: 2020 2nd IEEE International Conference on Advanced Trends in Information Theory, ATIT 2020, vol. 349344, pp. 307–310 (2020). https://doi.org/10.1109/ATIT50783.2020.9349344

Ladieva, L., Kozanevych, Z., Klusta, T., Korniyenko, B.: System of control of the process of alkylation of benzene with peripene in the liquid phase. In: Proceedings: 2020 2nd IEEE International Conference on Advanced Trends in Information Theory, ATIT 2020, vol. 9349330, pp. 311–314 (2020). https://doi.org/10.1109/ATIT50783.2020.9349330

Kornienko, Y.M., Sachok, R., Tsepkalo, O.V.: Modelling of multifactor processes while obtaining multilayer humic-mineral solid composites. Chemistry 20(3), E19–E26 (2011)

Kornienko, Ya.N., Podmogilnyi, N.V., Silvestrov, A.N., Khotyachuk, R.F.: Current control of product granulometric composition in apparatus with fluidized layer. J. Autom. Inf. Sci. 31(12), 97–106 (1999)

Babak, V., Shchepetov, V., Nedaiborshch, S.: Wear resistance of nanocomposite coatings with dry lubricant under vacuum. Sci. Bull. Natl. Min. Univ. (1), 47–52 (2016)

Kravets, P., Shymkovych, V.: Hardware implementation neural network controller on FPGA for stability ball on the platform. In: Hu, Z., Petoukhov, S., Dychka, I., He, M. (eds.) ICCSEEA 2019. AISC, vol. 938, pp. 247–256. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-16621-2_23

Babak, V.P., Babak, S.V., Myslovych, M.V., Zaporozhets, A.O., Zvaritch, V.M.: Methods and models for information data analysis. In: Babak, V.P., Babak, S.V., Myslovych, M.V., Zaporozhets, A.O., Zvaritch, V.M. (eds.) Diagnostic Systems For Energy Equipments. SSDC, vol. 281, pp. 23–70. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-44443-3_2

Shymkovych, V., Telenyk, S., Kravets, P.: Hardware implementation of radial-basis neural networks with Gaussian activation functions on FPGA. Neural Comput. Appl. 33(15), 9467–9479 (2021). https://doi.org/10.1007/s00521-021-05706-3

Karthika, B.S., Deka, P.C.: Modeling of air temperature using ANFIS by wavelet refined parameters. Int. J. Intell. Syst. Appl. 8(1), 25–34 (2016). https://doi.org/10.5815/ijisa.2016.01.04

Ghiasi-Freez, J., Hatampour, A., Parvasi, P.: Application of optimized neural network models for prediction of nuclear magnetic resonance parameters in carbonate reservoir rocks. Int. J. Intell. Syst. Appl. (IJISA) 7(6), 21–32 (2015). https://doi.org/10.5815/ijisa.2015.06.02

Malekzadeh, M., Khosravi, A., Noei, A.R., Ghaderi, R.: Application of adaptive neural network observer in chaotic systems. Int. J. Intell. Syst. Appl. 6(2), 37–43 (2014). https://doi.org/10.5815/ijisa.2014.02.05

Bhagawati, K., Bhagawati, R., Jini, D.: Intelligence and its application in agriculture: techniques to deal with variations and uncertainties. Int. J. Intell. Syst. Appl. (IJISA) 8(9), 56–61 (2016). https://doi.org/10.5815/ijisa.2016.09.07

Wang, W., Cui, L., Li, Z.: Theoretical design and computational fluid dynamic analysis of projectile intake. Int. J. Intell. Syst. Appl. (IJISA) 3(5), 56–63 (2011). https://doi.org/10.5815/ijisa.2011.05.08

Patnaik, P., Das, D.P., Mishra, S.K.: Adaptive inverse model of nonlinear systems. Int. J. Intell. Syst. Appl. 7(5), 40–47 (2015). https://doi.org/10.5815/ijisa.2015.05.06

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Korniyenko, B., Ladieva, L., Bereza, O. (2022). Optimal Control with Prediction for the Process of Vacuum Membrane Distillation. In: Hu, Z., Zhang, Q., Petoukhov, S., He, M. (eds) Advances in Artificial Systems for Logistics Engineering. ICAILE 2022. Lecture Notes on Data Engineering and Communications Technologies, vol 135. Springer, Cham. https://doi.org/10.1007/978-3-031-04809-8_4

Download citation

DOI: https://doi.org/10.1007/978-3-031-04809-8_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-04808-1

Online ISBN: 978-3-031-04809-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)