Abstract

Materials serve as the foundation of the technical framework on which modern society relies every day. Generations have developed new materials, tried to understand the origins of their properties, and found ways to predict them. Modern computational tools have vastly expanded our capabilities to make predictions, not only of material properties but also of component properties and of the component health status over its life cycle. Integrated Computational Materials Engineering (ICME) aims at simulating the material and component properties along the complete process chain and across the length scales from microstructure to component scale. In this way a digital twin of the material or component can be generated, which can be leveraged to facilitate gains in productivity and service life of technical systems. By reducing the complexity of models for the digital twin where necessary, combining them with in-process data using innovative sensor technology and suitable mathematically driven approximation procedures such as machine learning, it is possible to conceive a digital material shadow that resolves elements of the dilemma between data granularity, data volume, and processing speed to enable process monitoring and control for materials processing. To enable communication between humans and machines it is necessary to create a strictly defined language in the form of ontologies. Ontologies are typically domain-specific, but care must be taken to make them consistent across domains. Integrated Structural Health Engineering (ISHE) aims at predicting and monitoring the health state of components over their entire life cycle, enabling timely replacement of components and avoiding costly and possibly life-threatening failures. In particular when components are subjected to cyclic loading, their structural health does not primarily depend on the average material properties, but on the presence of more or less statistically distributed defects. These defects are intrinsic to materials processing, cannot be completely avoided, and evolve during various stages of the production process. The objective of ISHE is to predict their formation and evolution during the production process and their impact on the component structural health during its life cycle. It is clear that the material and component properties are strongly dependent on the process by which they are produced. Therefore, many of the topics discussed in this part have relational counterparts in Part IV: Production.

You have full access to this open access chapter, Download reference work entry PDF

Similar content being viewed by others

Keywords

- Integrated Computational Materials Engineering

- Integrated Structural Health Engineering

- Machine learning

- Ontologies

- Simulation platform

- Digital materials shadow

- Digital component shadow

1 Introduction

The development of computer power and simulation methods has led to enormous advances in the last few decades. Simulation models are increasingly used for material and process development and a large number of simulation tools are now available. Today, they describe phenomena on all time and length scales relevant to materials and can often be run on a standard laptop, even for complex simulations. Currently, these software solutions have reached a level in their respective fields that allows valuable contributions to modern design tasks in knowledge-based production models. The aim is to provide digital material and component models (digital twins and digital shadows) that can be used in the wider context of the Internet of Production. Three Workstreams have been defined to highlight various aspects of the ICME and ISHE methods and show how digital twins and digital shadows can be derived and leveraged to enable a targeted response to the individual defect density. The Workstreams to be described in the three following chapters are “Material Solutions to Increase the Information Density in Mold-Based Production Systems,” “Towards Holistic Digital Material Description During Press-Hardening,” and “Materials in the Drive Chain: Modeling Materials for the Internet of Production.”

2 ICME in a Production Environment

Overall, the complex interaction of atomistic processes, thermodynamics, process conditions, microstructure development, material, and component properties can only be described by combining different simulation and machine learning (ML) tools within the framework of an “Integrated Computational Materials Engineering” (ICME) approach.

The history of ICME actually began with the first use of computers in materials science at all and has led via "Computational Thermodynamics" to the CALPHAD methodology (Lukas et al. 2007; Saunders and Miodownik 1998) and further to spatially resolved simulations of microstructure formation using the multi-phase field methodology, to crystal plasticity models and many more. Currently, a heterogeneous variety of hundreds of software tools related to ICME is available (Schmitz and Prahl 2016).

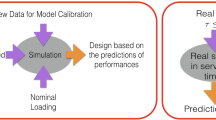

The basic idea of ICME is to simulate the material and the component through the complete process chain, from raw materials to finished component, and across the length scales, from atomic scale to component scale. The simulation results from one step in the process chain then form the input for the next step. In this way digital material/component twins and shadows can be constructed. The fast digital shadows with specifically reduced information content can be augmented by in-process data and can, thus, be used to control the process to achieve the final desired component properties. The properties of materials are largely determined by the microstructure, i.e., the distribution of phases, grain size (crystallite size), amount and distribution of dislocations, etc. The formation of the microstructure is ultimately determined by processes on the atomic scale. To reach component scale properties it is therefore necessary to use model-reduction and scale bridging to sufficiently coarse-grain the models to make them usable at the component scale without sacrificing the physics inherent in the lower scale models (Heo et al. 2021).

ICME in contemporary material concepts aims at improved properties by adapting and tailoring the microstructure. Several trends are of interest here: the quantitative evaluation of very small microstructure components on the nm scale, the description of very inhomogeneous microstructures, a higher level of alloying and the interaction of different alloying elements associated with it, the incorporation of metastable phases, and eventually the determination of effective material properties by means of mathematical homogenization and virtual tests The use of ICME methods leads to an understanding of the underlying physical phenomena, enables faster material and process development, and increases process reliability and robustness.

Applying ICME for new material classes and new production methods allows efficiently rethinking design approaches and entire components. An example is performance-oriented material development under the aspects of strain hardening engineering (SHE) using the possibilities resulting from the use of additive manufacturing processes (AM).

3 Integrated Structural Health Engineering

The fatigue strength of a component is often determined by defects. These defects can either be surface defects created during the production or usage as a result of, e.g., wear or corrosion, or they can be internal defects, typically created at the very beginning of the process chain and modified throughout the process chain. Critical internal defects may be relatively rare, but even if only one component in one thousand has a critical internal defect, which actually reduces the component lifetime, the failure of this component must be prevented by timely repair or replacement. Traditionally, this is achieved by regular maintenance intervals where components are inspected for damage. Within Structural Health Monitoring (SHM) (Farrar et al. 2001; Strantza et al. 2015) this can be augmented by using sensors to capture damage in situ using, e.g., changes in acoustic, vibrational, or compliance properties. This is particularly important when the component is not easily available for inspection. Integrated Structural Health Engineering (ISHE) offers a more holistic approach by including also the production process chain and extend the ICME generated Digital Material Shadow to a Digital Component Shadow, which includes the components health status with a prediction of its residual lifetime. Defects can be assumed to be distributed statistically within the material, but only the tail-end of the distribution is of particular interest here. By the combination of sensors and machine learning methods, process conditions that can result in defect formation can be identified. The evolution of the defects can be predicted and influenced with the help of the ICME tools used to produce the Digital Material Shadow. Statistical methods combined with ML methods are then used to predict their location within components and the resulting impact on the component’s predicted fatigue life.

4 Machine Learning

Machine learning methods can complement or replace simulation models if sufficient data are available. Due to the black-box behavior of most of these methods, increasing the understanding of their outcome is of great importance to improve their prediction quality. For this purpose, mathematical tools can be applied. To give an example, a special type of residual neural networks (ResNets) has an underlying structure which allows for analyzing at least simple ResNets using mathematical techniques from kinetic gas dynamics (Herty et al. 2022). Furthermore, classical or deep neural networks can be linked to physics by incorporating the governing equations of the problem at hand. The resulting physics-informed neural networks (PINNs) compute the residuals of the underlying partial differential equations applying automatic differentiation of the neural network outputs to optimize the training of the network (Raissi et al. 2019). If the governing equations are only partly known, PINNs even allow for the data-driven discovery of underlying physics, e.g., by determining unknown parameters.

A common problem of an already trained machine learning method is its limited reusability. A neural network may have to be retrained if, e.g., a material component in a production process is modified. Efficient transfer learning algorithms such as ensemble Kalman filtering (Kovachki and Stuart 2019) allow for a fast retraining in settings where only few external conditions change (Herty et al. 2021).

5 Ontologies for ICME

Future ICME will be based on interoperability. The interaction – i.e., “interoperability” – between different simulation tools, between experiment and simulation, between product and manufacturing process, between human and computer, between models and data, and between different knowledge and experience domains requires a “common language” which is understood by both machines and humans. Especially enhanced interoperability between data and models will lead to new models being based on production data or on experimental data (AI) and especially to model- (or physics-) informed neural networks, e.g., Torabi Rad et al. (2020).

Current trends in ICME thus are based on the development, the use, and the modular configuration of ontologies. Ontologies are at the top of the semantic spectrum stretching from symbol, via keyword, thesaurus, syntax, semantics, taxonomy, ontology eventually up to epistemology (Obrst 2010). In addition to the hierarchical “isA” relation” used in taxonomy, ontologies provide further relations between different classes of things. These additional relations may be arbitrarily selected (“lightweight ontologies”) or are based on fundamental concepts of analytical philosophy like mereology (Casati and Varzi 1999; Schmitz 2020), mereotopology (Schmitz 2022), causality (Ghedini et al. 2022), and semiosis (Atkin 2010) being formulated in first-order logics (“heavyweight ontologies”).

Application of ontologies in industrial settings requires the fundamental philosophical concepts to be exposed to harsh environments of industrial production. Such applications in fact can be attained when harnessing a foundational core ontology by suitable domain ontologies. The Elementary Multiperspective Material Ontology EMMO (EMMO 2022) is a foundational ontology providing the framework for standardized integration and a modular, re-useable configuration of a variety of domain ontologies. EMMO in this context is not the only foundational ontology. Other foundational ontologies are BFO (Arp et al. 2015), BORO method (BORO 2021), Dublin Core (2022), GFO (Herre et al. 2007), Cyc/OpenCyc/ResearchCyc (Cyc 2022), SUMO (2021), UMBEL (2021), UFO (Nardi et al. 2013), DOLCE (Borgo and Masolo 2010; Gangemi et al. 2002), WordNet (2022), and OMT/OPM (Dori 2002; OPM 2022). Their harmonization toward a unifying Top Reference Ontology (TRO) is an on-going effort of a European research project (OntoCommons 2022).

5.1 Ontologies in Materials

The 118 chemical elements in the periodic table being relevant in everyday life are a result of combinations of only a subset of the elementary particles. The standard reference covering chemical elements is the IUPAC Gold Book (Gold 2019). Combinations of different chemical elements lead to an exploding variety of possible substances and arrangements like molecules, crystals, nanoparticles, and eventually all bulk materials constituting the macroscopic production world. For almost each of these classes there exist some individual taxonomies or ontologies like the CheBi (“Chemical Substances of Biological interest” (ChEBI 2018)), the Nanoparticle Ontology (NPO (Thomas et al. 2011)), Environmental Material Ontology (ENVO (Buttigieg et al. 2016)), or the Crystallographic Information File (CIF (Brown and McMahon 2002)). Further classification of materials often proceeds by chemical composition. Ceramics in general are distinguished into oxides, carbides, nitrides, silicides to name a few. Metals and alloys are first classified by the major chemical element like Al-alloys, Fe–alloys/steels, Ni-alloys, Cu-alloys. Taxonomies of technical materials are widely used in characterization and reliability fields of materials engineering to distinguish various industrially used alloys, metals, and ceramics. The International Alloy Designation System, for example, is the most widely accepted classification and naming scheme for aluminum-based alloys enabling automated and human interpretation of the type of materials by a digit-based encoding system, e.g., “Al 6061” (Aluminium Alloy 2022). Even for the same overall chemical composition, however, the properties of the resulting material still depend on the way it was further processed, e.g., in tempering processes. The respective temper designation thus follows the digit-based designation number with a dash, e.g., 6061-T6. The definitions for the tempers are, e.g., (for a full list see (Aluminium Alloy 2022)): -F (as fabricated), -H, and -T. Current Material Databases (e.g. (Ansys Granta 2022)) provide compilations of processing and property data for a huge variety of alloys, compounds, and substances.

From the end user perspective, the ultimate functionality of the material is the major topic of interest. These end users are not at all interested in any detail of the material like its microstructure or its composition. These users are interested in knowing the effective properties of the volume filled by the material. Current trends of materials taxonomy and more specifically ontology developments thus direct toward a sub-domain and/or particular application specific focus, e.g., Ceramics (van der Vet et al. 1994), Structural Materials (Ashino 2010), Composites (Premkumar et al. 2014), Alloys (Zhang et al. 2016), Catalysts (Takahashi et al. 2018), or Functionally Graded Materials (Furini et al. 2016). In many cases nowadays the microstructure of a material is considered as the state variable defining the materials properties. Semantic microstructure descriptions thus increasingly become subject of ontology development using a standardized nomenclature (CWA 17284 2018), suitable metadata descriptions (Schmitz et al. 2016), and eventually a foundational ontology framework like EMMO. EMMO compliant domain material ontologies have already been developed for characterization (Morgado et al. 2020) and crystallography (CIF ontology 2022), and currently are under development for microstructure and thermodynamics within task groups of the European Materials Modelling Council (EMMC ASBL (EMMC 2022; EMMC Task Group 2022)).

5.2 Ontologies in Production

Quite a number of ontologies related to different aspects of production have emerged over the years, Fig. 1.

Table of some contemporary ontologies in the area of production. (Reproduced from (Borgo and Leitão 2007))

They are not harmonized neither in terms of their underlying foundational ontology nor in the general use ontological relations being somehow arbitrary and not being based on first-order logic concepts. Accordingly, most of them have to be considered as “lightweight” ontologies. The diversity of the underlying foundational ontologies and the heterogeneity of the ontological relations being used make this variety of ontologies hardly be configurable and mutually interoperable. An example is the ADACOR ontology (Borgo and Leitão 2007) being based on the DOLCE (Borgo and Masolo 2010; Gangemi et al. 2002) foundational ontology.

Scope of all types of production ontologies is to make production – and also all product – data FAIR meaning Findable, Accessible, Interoperable, and Re-usable. Production data as well as in-service life product data can be classified into dynamic DataStreams and static DataTraces. DataStreams can further be sub-classified into SensorDataStreams and ActuatorDataStreams. SensorDataStreams provide all information about the actual state of the production system. Their recording into static DataTraces allows tracing the history of the entire production system. DataTraces, i.e., stored information, also comprise all static information about the production system like information on machinery, their arrangement in the production system, geometries of product components, etc. The SensorDataStream along with the available DataTraces comprehensively describes the actual status of the production system including short-term evolution trends and thus the “data of today.” The ActuatorDataStream, in contrast, comprises all types of data allowing to intentionally and actively “change” the state of the production system, e.g., by changing controller settings or simply stopping a machine. The ActuatorDataStream thus provides the data for an intended behavior of the production system “tomorrow,” Fig. 2.

Sensor DataStreams and ActuatorDataStreams are the only interfaces providing knowledge of the production system or allowing to influence its behavior. Solely based on these data, a neural network could be trained or other models be informed. No notion about the actual production machinery would be necessary

5.3 Modular Configurable and Re-Usable Ontologies

Contemporary ontologies in many cases have been developed independently and aiming at adequately covering the knowledge of the respective domain. In many cases the full specification of notions also being important for other domains was necessary. Examples for ontologies of common interest and likely to be used in many domain ontologies are, e.g., ontologies for SI-units, for basic mathematical operations and expression, for basic chemistry, thermodynamics, and crystallography to name a few. A modular configurable set of mid-level ontologies bridging between the foundational ontology and the application-oriented domain ontologies thus is highly desirable. The Elementary Multiperspective Material Ontology EMMO supports such a strategy and quite a number of mid-level and domain ontologies are already publicly available (EMMO Middle 2021).

One of the scopes of IOP work was to structure the domain of “Industry 4.0” and to identify the required domain ontologies, which have to match the language of industrial production. In detail EMMO compliant domain ontologies/taxonomies for ManufacturingProcesses, for ProductionSystems, for ContinuumMaterials, and for ModellingSoftware were developed. The ManufacturingProcess taxonomy, Fig. 3, has been defined based on established standards (DIN8580) and realized in English language using a standardized translation.

The ManufacturingProcess ontology is one of the building blocks of an overarching, modular ontological framework. The vision of such a future modular framework of an industrial setting and its actual status is outlined in Fig. 4.

Modular configurable system of domain ontologies for an industrial setting. Squares denote the ontological description of a state, while ellipsoidals represent ontological descriptions of processes. The arrows indicate ontological relations based on mereology and mereotopology (Casati and Varzi 1999; Schmitz 2020, 2022). Processes havePart other processes (e.g., SensorProcess hasPart SensorDataStream) and have participants, which are states (e.g., SensorProcess hasParticipant SensorSystem). The cream-colored ontology screenshots indicate the currently available taxonomies/ontologies

Emerging domain ontologies for SensorSystems, ActuatorSystems, DataStreams and DigitalShadows as currently developed in the CoE (Becker et al. 2021) will be integrated soon and complement the overall ontological framework. Especially the MaterialOntology will be further connected to the numerous relevant domain ontologies like a MicrostructureOntology, a CrystallographicOntology, and many others already introduced in the section on material ontologies. Eventually this will allow to link production process data to material property data and vice versa. The modular ontological framework then will allow to also include further domain ontologies like production planning, logistics, business, and finance and many more.

6 Simulation Platforms

Once interoperability between a variety of models and data is obtained there is a chance for the realization of integrating workflows allowing the description of materials and components along their entire production and service life-cycle. The major requirements for a “simulation platform” are: (i) suitable and available hardware (e.g., cloud, grid, HPC), (ii) a comprehensive set of relevant and modular configurable software, (iii) a workload manager, and (iv) a workflow orchestrator. In case commercial codes or proprietary data are involved there is a further need for (v) a user and access rights management and eventually for (vi) back office solutions, e.g., for accounting purposes.

Quite a number of simulation platforms are nowadays available, Fig. 5, with a number of them being harmonized and integrated into a metaplatform being currently under development in the MarketPlace project (MarketPlace 2022).

Currently known open simulation platforms (DGM 2022). Open in this context means the backbone of the platform to be opensource resp. open access and contrasts to commercial platforms like 3D experience or Ansys workbench

Work within the Cluster of Excellence in this area has been focused on AixViPMaP, which is based on a first concept for an ICME simulation platform addressing process chains being proposed about a decade ago (Schmitz and Prahl 2012). The AixViPMaP platform since then has significantly matured and now is operational for microstructure simulation workflows adaptable to different metallic systems and process conditions (Koschmieder et al. 2019).

Workflows on AixViPMaP (and also on many other platforms) are orchestrated by Jupyter notebooks invoking software modules of different classes: “Creators” serve to generate an initial virtual material state and may also comprise experimental data. “Evolvers” advance this state according to process conditions. “Extractors” eventually calculate properties from a state, while not altering it. The material state data is stored in a HDF5 file being consecutively updated with new data throughout the workflow eventually leading to a full description of a microstructure at given conditions. AixViPMaP (www.aixvipmap.de) can be run either in the cloud or on a grid with the workload distribution being controlled by a HT Condor middleware. Essentially the AixViPMaP is software agnostic and thus basically all types of software can be run, with the minimum requirement being a batch execution capability. Integrated Computational Materials Engineering (ICME) is characterized by application and combination of multiple simulation software tools and a variety of data. A respective cloud-based infrastructure comprising dedicated commercial and open access simulation tools has successfully been used not only for first research projects but also already during an interactive online training/education event (Koschmieder et al. 2021).

7 Conclusion

By the use of Integrated Computational Materials Engineering (ICME) a digital twin of the material or component can be derived. By combining the digital twin with in process data and machine learning it is possible to conceive a digital materials shadow. By the use Integrated Structural Health Engineering (ISHE) the health state of components can be monitored during their entire life cycle to avoid failures and enable timely replacement. To enable communication between humans and machines, it is necessary to create a strictly defined language in the form of ontologies.

References

Aluminium Alloy (2022) https://en.wikipedia.org/wiki/Aluminium_alloy. Accessed 29 April 2022

Ansys Granta (2022) https://grantadesign.com/industry/products/data/. Accessed 29 April 2022

Arp R, Smith B, Spear AD (2015) Building ontologies with basic formal ontology. MIT, Cambridge

Ashino T (2010) Materials ontology: an infrastructure for exchanging materials information and knowledge. Data Sci J 9:54–61. https://doi.org/10.2481/dsj.008-041

Atkin A (2010) Peirce’s theory of signs. https://plato.stanford.edu/entries/peirce-semiotics/. Accessed 29 April 2022

Becker F, Bibow P, Dalibor M, Gannouni A, Hahn V, Hopmann C, Jarke M, Koren I, Kröger M, Lipp J, Maibaum J, Michael J, Rumpe B, Sapel P, Schäfer N, Schmitz GJ, Schuh G, Wortmann A (2021) A conceptual model for digital shadows in industry and its application. In: Ghose A, Horkoff J, Silva Souza VE, Parsons J, Evermann J (eds) Conceptual modeling, vol 13011. Springer International Publishing, Cham, pp 271–281

Borgo S, Leitão P (2007) Foundations for a core ontology of manufacturing. In: Sharda R, Voß S, Sharman R, Kishore R, Ramesh R (eds) Ontologies, vol 14. Springer US, Boston, pp 751–775

Borgo S, Masolo C (2010) Ontological foundations of dolce. In: Poli R, Healy M, Kameas A (eds) Theory and applications of ontology: computer applications. Springer, Netherlands, pp 279–295

BORO (2021) https://en.wikipedia.org/wiki/BORO. Accessed 29 April 2022

Brown ID, McMahon B (2002) CIF: the computer language of crystallography. Acta Crystallogr B 58:317–324. https://doi.org/10.1107/S0108768102003464

Buttigieg PL, Pafilis E, Lewis SE, Schildhauer MP, Walls RL, Mungall CJ (2016) The environment ontology in 2016: bridging domains with increased scope, semantic density, and interoperation. J Biomed Semant 7:57. https://doi.org/10.1186/s13326-016-0097-6

Casati R, Varzi AC (1999) Parts and places: the structures of spatial representation. MIT Press, Cambridge

ChEBI (2018) https://www.ebi.ac.uk/chebi/. Accessed 29 April 2022

CIF ontology (2022) https://github.com/emmo-repo/CIF-ontology. Accessed 29 April 2022

CWA 17284 (2018) Materials modelling – terminology, classification and metadata. CEN

Cyc (2022) https://en.wikipedia.org/wiki/Cyc. Accessed 29 April 2022

DGM (2022) Simulation platforms and interoperability. https://dgm.de/en/network/expert-joint-committees/materials-modelling-simulation-and-data/simulation-platforms-and-interoperability. Accessed 29 April 2022

Dori D (2002) Object-process methodology: a holistic systems paradigm. Springer, Berlin Heidelberg

Dublin Core (2022) https://en.wikipedia.org/wiki/Dublin_Core. Accessed 29 April 2022

EMMC (2022) The European Materials Modelling Council. https://emmc.eu/. Accessed 29 April 2022

EMMC Task Group (2022) Interoperability. https://emmc.eu/focus-areas/interoperability/. Accessed 29 April 2022

EMMO (2022) https://emmc.info/emmo-info. Accessed 29 April 2022

EMMO Middle (2021) https://github.com/emmo-repo/EMMO/tree/master/middle. Accessed 29 April 2022

Farrar CR, Sohn H, Fugate ML, Czarnecki JJ (2001) Integrated structural health monitoring. In: Kundu T (ed) Advanced nondestructive evaluation for structural and biological health monitoring. SPIE

Furini F, Rai R, Smith B, Colombo G, Krovi V (2016) Development of a manufacturing ontology for functionally graded materials. In: Volume 1B: 36th Computers and Information in Engineering Conference. ASME

Gangemi A, Guarino N, Masolo C, Oltramari A, Schneider L (2002) Sweetening ontologies with DOLCE. In: Goos G, Hartmanis J, van Leeuwen J, Gómez-Pérez A, Benjamins VR (eds) Knowledge engineering and knowledge management: ontologies and the semantic web. Springer, Berlin/Heidelberg, pp 166–181

Ghedini E, Friis J, Goldbeck G, Hashibon A, Schmitz GJ, Moruzzi S (2022) EMMO – The elementary multiperspective material ontology. in preparation

Gold V (2019) The IUPAC compendium of chemical terminology. IUPAC, Research Triangle Park

Heo TW, Khairallah SA, Shi R, Berry J, Perron A, Calta NP, Martin AA, Barton NR, Roehling J, Roehling T, Fattebert J-L, Anderson A, Nichols AL, Wopschall S, King WE, McKeown JT, Matthews MJ (2021) A mesoscopic digital twin that bridges length and time scales for control of additively manufactured metal microstructures. J Phys Mater 4:34012. https://doi.org/10.1088/2515-7639/abeef8

Herre H, Heller B, Burek P, Hoehndorf R, Loebe F, Michalek H (2007) General Formal Ontology (GFO): A foundational ontology integrating objects and processes. Part I: Basic principles. https://www.onto-med.de/ontologies/gfo. Accessed 29 April 2022

Herty M, Rom M, Visconti G (2021) Einsparung kostenintensiver Experimente und Simulationen durch Maschinelles Lernen. In: Trauth D, Bergs T, Prinz W (eds) Monetarisierung von technischen Daten. Springer, Berlin/Heidelberg, pp 691–709

Herty M, Trimborn T, Visconti G (2022) Mean-field and kinetic descriptions of neural differential equations. Found Data Sci 0:0. https://doi.org/10.3934/fods.2022007

Koschmieder L, Hojda S, Apel M, Altenfeld R, Bami Y, Haase C, Lin M, Vuppala A, Hirt G, Schmitz GJ (2019) AixViPMaP®—an operational platform for microstructure modeling workflows. Integr Mater Manuf Innov 8:122–143. https://doi.org/10.1007/s40192-019-00138-3

Koschmieder L, Altenfeld R, Eiken J, Böttger B, Schmitz GJ (2021) Cloud-based ICME software training. Educ Sci 11:5. https://doi.org/10.3390/educsci11010005

Kovachki NB, Stuart AM (2019) Ensemble Kalman inversion: a derivative-free technique for machine learning tasks. Inverse Problems 35:95005. https://doi.org/10.1088/1361-6420/ab1c3a

Lukas HL, Fries SG, Sundman B (2007) Computational thermodynamics. The CALPHAD method. Cambridge University Press, Cambridge

MarketPlace (2022) MARKETPLACE – Materials modelling marketplace for increased industrial innovation. https://the-marketplace-project.eu. Accessed 29 April 2022

Morgado JF, Ghedini E, Goldbeck G, Hashibon A, Schmitz GJ, Friis J, de Baas AF (2020) Mechanical testing ontology for digital-twins: a roadmap based on EMMO. In: Garcia-Castro R, Davies J, Antoniou G, Fortuna C (eds) Semantic digital twins 2020. CEUR

Nardi JC, Falbo RdA, Almeida JPA, Guizzardi G, Pires LF, van Sinderen MJ, Guarino N (2013) Towards a commitment-based reference ontology for services. In: 2013 17th IEEE International Enterprise Distributed Object Computing Conference. IEEE, pp 175–184

Obrst L (2010) Ontological architectures. In: Poli R, Healy M, Kameas A (eds) Theory and applications of ontology: computer applications. Springer, Netherlands, pp 27–66

OntoCommons (2022) https://www.ontocommons.eu. Accessed 29 April 2022

OPM (2022). https://en.wikipedia.org/wiki/Object_Process_Methodology. Accessed 29 April 2022

Premkumar V, Krishnamurty S, Wileden JC, Grosse IR (2014) A semantic knowledge management system for laminated composites. Adv Eng Inform 28:91–101. https://doi.org/10.1016/j.aei.2013.12.004

Raissi M, Perdikaris P, Karniadakis GE (2019) Physics-informed neural networks: a deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J Comput Phys 378:686–707. https://doi.org/10.1016/j.jcp.2018.10.045

Saunders N, Miodownik AP (1998) CALPHAD (calculation of phase diagrams). A comprehensive guide. Pergamon, Oxford/New York

Schmitz GJ (2020) Quantitative mereology: an essay to align physics laws with a philosophical concept. Phys Essays 33:479–488

Schmitz GJ (2022) A phase-field perspective on mereotopology. Appl Math 2:54–103. https://doi.org/10.3390/appliedmath2010004

Schmitz GJ, Prahl U (2012) Integrative computational materials engineering – concepts and applications of a modular simulation platform. Wiley-VCH, Weinheim

Schmitz GJ, Prahl U (2016) Handbook of software solutions for ICME. Wiley-VCH, Weinheim

Schmitz GJ, Böttger B, Apel M, Eiken J, Laschet G, Altenfeld R, Berger R, Boussinot G, Viardin A (2016) Towards a metadata scheme for the description of materials – the description of microstructures. Sci Technol Adv Mater 17:410–430. https://doi.org/10.1080/14686996.2016.1194166

Strantza M, Baere D de, Rombouts M, Maes G, Guillaume P, van Hemelrijck D (2015) Feasibility study on integrated structural health monitoring system produced by metal three-dimensional printing. Struct Health Monit 14:622–632. doi:https://doi.org/10.1177/1475921715604389

SUMO (2021) https://en.wikipedia.org/wiki/Suggested_Upper_Merged_Ontology. Accessed 29 April 2022

Takahashi L, Miyazato I, Takahashi K (2018) Redesigning the materials and catalysts database construction process using ontologies. J Chem Inf Model 58:1742–1754. https://doi.org/10.1021/acs.jcim.8b00165

Thomas DG, Pappu RV, Baker NA (2011) NanoParticle ontology for cancer nanotechnology research. J Biomed Inf 44:59–74. https://doi.org/10.1016/j.jbi.2010.03.001

Torabi Rad M, Viardin A, Schmitz GJ, Apel M (2020) Theory-training deep neural networks for an alloy solidification benchmark problem. Comput Mater Sci 180:109687. https://doi.org/10.1016/j.commatsci.2020.109687

UMBEL (2021) https://en.wikipedia.org/wiki/UMBEL. Accessed 29 April 2022

van der Vet PE, Speel P-H, Mars NJ (1994) The Plinius ontology of ceramic materials. In Proceeding if the 11th European Conference on Artificial Intelligence (ECAI’94)

WordNet (2022) https://en.wikipedia.org/wiki/WordNet. Accessed 29 April 2022

Zhang X, Pan D, Zhao C, Li K (2016) MMOY: towards deriving a metallic materials ontology from Yago. Adv Eng Inform 30:687–702. https://doi.org/10.1016/j.aei.2016.09.002

Acknowledgment

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy – EXC-2023 Internet of Production – 390621612.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this entry

Cite this entry

Broeckmann, C. et al. (2023). Materials Within a Digitalized Production Environment. In: Brecher, C., Schuh, G., van der Aalst, W., Jarke, M., Piller, F.T., Padberg, M. (eds) Internet of Production. Interdisciplinary Excellence Accelerator Series. Springer, Cham. https://doi.org/10.1007/978-3-030-98062-7_6-1

Download citation

DOI: https://doi.org/10.1007/978-3-030-98062-7_6-1

Received:

Accepted:

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-98062-7

Online ISBN: 978-3-030-98062-7

eBook Packages: Springer Reference EngineeringReference Module Computer Science and Engineering