Abstract

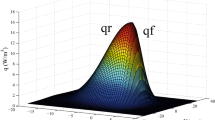

At some of industrial enterprises, electron-beam welding technology is used in processes requiring the formation of permanent connections between equipment elements. However, its application is complicated by the need for accurate selection of the values of technological parameters. The software system proposed in this work allows simulating the temperature distribution over the volume of the products to be joined in the process of electron beam welding. The theory of welding processes is used as a mathematical apparatus. The software system has a modular structure and consists of six subsystems that implement specific functionality. All data, both input for mathematical models and results are stored in a single database, consisting of nine joined tables. The use of the proposed software allows both to reduce the cost and simplify the process of adjusting the technological parameters of electron beam welding, and to form the basis for the further implementation of effective control systems.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Frank, A.G., Dalenogare, L.S., Ayala, N.F.: Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 210, 15–26 (2019)

Gorecky, D., Schmitt, M., Loskyll, M., Zühlke, D.: Human-machine-interaction in the industry 4.0 era. In: 2014 12th IEEE International Conference on Industrial Informatics (INDIN), pp. 289–294 (2014)

Bai, C., Dallasega, P., Orzes, G., Sarkis, J.: Industry 4.0 technologies assessment: a sustainability perspective. Int. J. Prod. Econ. 229, 107776 (2020)

Saucedo-Martínez, J.A., Pérez-Lara, M., Marmolejo-Saucedo, J.A., Salais-Fierro, T.E., Vasant, P.: Industry 4.0 framework for management and operations: a review. J. Amb. Intell. Hum. Comput. 9(3), 789–801 (2018)

Ghobakhloo, M.: Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 252,119869 (2020)

Zheng, T., Ardolino, M., Bacchetti, A., Perona, M.: The applications of Industry 4.0 technologies in manufacturing context: a systematic literature review. Int. J. Prod. Res. 59(6), 1922–1954 (2021)

Yunlian, Q., Ju, D., Quan, H., Liying, Z.: Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater. Sci. Eng. A280, 280(1), 177–181 (2000)

Salomatova, E.S.: Electron beam welding - from invention to the present day. Bull. Perm Natl. Res. Polytech. Univ. Mech. Eng. Mater. Sci. 1, 74–87(2013)

Permyakov, G.L., Olshanskaya, T.V., Belenkiy, V.Ya., Trushnikov, D.: Simulation of electron beam welding to determine the parameters of welded joints of dissimilar materials. Bull. Perm Natl. Res. Polytech. Univ. Mech. Eng. Mater. Sci. 1(4), 48–58 (2013)

Yang, Z., Fang, Y., He, J.: Numerical investigation on molten pool dynamics and defect formation in electron beam welding of aluminum alloy. J. Mater. Eng. Perform. 29(10), 6570–6580 (2020). https://doi.org/10.1007/s11665-020-05111-2

Yang, Z., Fang, Y., He, J.: Numerical simulation of heat transfer and fluid flow during vacuum electron beam welding of 2219 aluminium girth joints. Vacuum 175, 109256 (2020)

Kaisheva, D., Angelov, V., Petrov, P.: Simulation of heat transfer at welding with oscillating electron beam. Can. J. Phys. 97(10), 1140–1146 (2019)

Mladenov, G., Koleva, E., Belenky, V.Ya., Trushnikov, D.N.: Modeling and optimization of electron beam welding of steels. Bull. Perm Natl. Res. Polytech. Univ. Mech. Eng. Mater. Sci. 16(4), 7–21 (2014)

Kanigalpula, P.K.C., Jaypuria, S., Pratihar, D.K., Jha, M.N.: Experimental investigations, input-output modeling, and optimization of spiking phenomenon in electron beam welding of ETP copper plates. Measurement 129(1), 302–318 (2018)

Luo, M., Hu, R., Liu, T., Wu, B., Pang, S.: Optimization possibility of beam scanning for electron beam welding: physics understanding and parameters selection criteria. Int. J. Heat Mass Transf. 127(1), 1313–1326 (2018)

Ignat'eva, M.A., Kadyrov, R.F., Mazo, A.B.: Calculation of the temperature field of a plate when electron-beam welding. Uchenye Zapiski Kazanskogo Universiteta. Seriya Fiziko-Matematicheskie Nauki 148(4), 23–34 (2006)

Das, D., Das, A.K., Pratihar, D.K., Roy, G.G.: Prediction of residual stress in electron beam welding of stainless steel from process parameters and natural frequency of vibrations using machine-learning algorithms. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 235, 2008–2021 (2020)

Luo, M., Hu, R., Liu, T., Wu, B., Pang, S.: Optimization possibility of beam scanning for electron beam welding: physics understanding and parameters selection criteria. Int. J. Heat Mass Transf. 127, 1313–1326 (2018)

Konovalov, A.V.: Theory of Welding Processes. Izd-vo MGTU im. N.E. Bauman, Moscow (2007)

MySQL. https://www.mysql.com/. Accessed 5 Jan 2021

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Tynchenko, V., Kurashkin, S. (2022). Software for Modeling the Electron-Beam Welding in Steady State. In: Radionov, A.A., Gasiyarov, V.R. (eds) Advances in Automation III. RusAutoCon 2021. Lecture Notes in Electrical Engineering, vol 857. Springer, Cham. https://doi.org/10.1007/978-3-030-94202-1_23

Download citation

DOI: https://doi.org/10.1007/978-3-030-94202-1_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-94201-4

Online ISBN: 978-3-030-94202-1

eBook Packages: EngineeringEngineering (R0)