Abstract

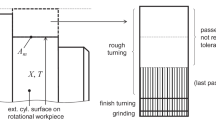

A mathematical model for the numerical determination of the quality indicator value allowing one to obtain non-dimensional values in the range from minus infinity to 1 (the maximum usable value) is proposed. Unlike the traditional system of tolerances, in which the suitability can take two values – 0 or 1, the proposed model allows you to obtain intermediate values of the suitability, depending on the proximity of the actual parameter to the desired value. The model uses the suitability function suggested in the paper, and the shape indicator drives it. The characteristic ranges of the shape indicator of the suitability function have been considered. Those of practical importance has been highlighted. In addition to the general dependence, exceptional cases (linear and parabolic suitability functions, which are mathematically simpler) are also given. It is shown how the use of the proposed model allows sorting parts into quality grades and introducing a technological margin of accuracy. The mathematical model is illustrated by the example of the dimensional suitability of an engineering part. The traditional system of dimensional tolerances is a particular case of the proposed generalized system, which is recommended for high-precision manufacturing.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Harrington, J.: The desirability function. Ind. Qual. Control 21(10), 494–498 (1965)

Derringer, G.C., Suich, D.: Simultaneous optimization of several response variables. J. Qual. Technol. 12(4), 214–219 (1980)

Kim, K.-J., Lin, D.: Simultaneous optimization of mechanical properties of steel by maximizing exponential desirability functions. Appl. Statist. 48(3), 311–325 (2000)

Pogrebjak, A.D., Krivets, A.S., Dyadyura, K.A., Maksakova, O.V., Shaimardanov, Zh.K., Peplinska, B.: Research of the relief and element composition of the surface coatings based on hydroxyapatite implants from titanium alloys. In: Nanomaterials: Applications & Properties (NAP–2016), vol. 5, no. 2 (2016). https://doi.org/10.1109/NAP.2016.7757290

Ngoi, B.K.A., Seow, M.S.: Tolerance control for dimensional and geometrical specifications. Int. J. Adv. Manuf. Technol. 11, 34–42 (1996). https://doi.org/10.1007/BF01177182

Trisch, R., Gorbenko, E., Dotsenko, N., Kim, N., Kiporenko, A.: Development of qualimetric approaches to the processes of quality management system at enterprises according to international standards of the ISO 9000 series. Eastern-Eur. J. Enterprise Technol. 4(3–82), 18–24 (2016). https://doi.org/10.15587/1729-4061.2016.75503

Wagner, T., Trautmann, H.: Integration of preferences in hypervolume-based multiobjective evolutionary algorithms by means of desirability functions. IEEE Trans. Evol. Comput. 14(5), 688–701 (2010)

Leblond, L., Pillet, M.: Conformity and statistical tolerancing. Int. J. Metrol. Qual. Eng. 9(1) (2018)

Babu, J.R., Asha, A.: Minimising assembly loss for a complex assembly using Taguchi’s concept in selective assembly. Int. J. Prod. Qual. Manag. 15(3), 335–356 (2015)

Pillet, M., Maire, J.L.: Inertial tolerancing and acceptance sampling. Int. J. Eng. Innov. Technol. 2(10), 265–271 (2013)

Pillet, M., Adragna, P.-A., Germain, F.: Inertial tolerancing: the sorting problem. J. Mach. Eng. 6(1), 95–102 (2006)

Kupriyanov, O., Lamnauer, N.: Improvement of the assembling technology for precision joints using the dimensional information. In: Tonkonogyi, V., et al. (eds.) InterPartner 2020. LNME, pp. 52–60. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-68014-5_6

Tamminen, S., et al.: From measurements to knowledge - online quality monitoring and smart manufacturing. In: Perner, P. (ed.) ICDM 2018. LNCS (LNAI), vol. 10933, pp. 17–28. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-95786-9_2

Singer, G., Yuval Cohen, Y.: A framework for smart control using machine-learning modeling for processes with closed-loop control in Industry 4.0. Eng. Appl. Artif. Intell. 102 (2021). https://doi.org/10.1016/j.engappai.2021.104236

Karaoglan, A., Bayhan, G.: A regression control chart for autocorrelated processes. Int. J. Ind. Syst. Eng. 16(2), 238–256 (2014). https://doi.org/10.1504/IJISE.2014.058838

Muller, T., Pillet, M., Maire, J.L., Pillet, D.: Why and how to move from SPC (statistical process control) to APC (automated process control). In: Aifaoui, N., et al. (eds.) CMSM 2019. LNME, pp. 33–40. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-27146-6_4

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Kupriyanov, O., Trishch, R., Dichev, D., Bondarenko, T. (2022). Mathematic Model of the General Approach to Tolerance Control in Quality Assessment. In: Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I. (eds) Advanced Manufacturing Processes III. InterPartner 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-91327-4_41

Download citation

DOI: https://doi.org/10.1007/978-3-030-91327-4_41

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-91326-7

Online ISBN: 978-3-030-91327-4

eBook Packages: EngineeringEngineering (R0)