Abstract

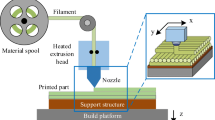

It is used for 3-dimensional (3D) production, which is called additive manufacturing, which emerged In the 1980s, with the inadequacy of traditional methods. Today, with the development of this technology, all kinds of geometry are produced rapidly. However, with 3D printing technology development, the problems are known as complexity have increased significantly. This situation made the fault analysis during the study a matter to be focused. User intervention is generally required in case of faulty in the parameters during printing using 3D printing technologies. The user must first observe whether there is any faulty and decide what to do. The study focused on automatic diagnostics to help the user diagnose the potential faulty and solve the problem. The data from the sensors belonging to the electronic card designed in the study were taken. The analog values were then read and analyzed, and the faulty conditions were checked according to the analysis. In the field of 3D printing technologies, a new approach has been presented by analyzing the data obtained in faulty analysis with the artificial intelligence method.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ngo, T.D., Kashani, A., Imbalzano, G., Nguyen, K.T., Hui, D.: Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. B Eng. 143, 172–196 (2018)

Herzog, D., Seyda, V., Wycisk, E., Emmelmann, C.: Additive manufacturing of metals. Acta Mater. 117, 371–392 (2016)

Singh, S., Ramakrishna, S., Singh, R.: Material issues in additive manufacturing: a review. J. Manuf. Process. 25, 185–200 (2017)

Rey, D.F.V., St-Pierre, J.P.: Department of Chemical and Biological Engineering, University of Ottawa, Ottawa, ON, Canada. Handbook of Tissue Engineering Scaffolds: Volume One, 109 (2019)

Tanzi, M.C., Farè, S., Candiani, G.: Foundations of Biomaterials Engineering. Academic Press, Cambridge (2019)

Walker, J.L., Santoro, M.: Processing and production of bioresorbable polymer scaffolds for tissue engineering. In: Bioresorbable Polymers for Biomedical Applications, pp. 181–203. Woodhead Publishing (2017)

El Naqa, I., Haider, M.A., Giger, M.L., Ten Haken, R.K.: Artificial intelligence: reshaping the practice of radiological sciences in the 21st century. Br. J. Radiol. 93(1106), 1–15 (2020)

Russell, S.J., Norvig, P.: Artificial Intelligence: A Modern Approach. Pearson Education Limited, Malaysia (2016)

Jiang, F., et al.: Artificial Intelligence in healthcare: past, present and future. Stroke Vasc. Neurol. 2(4), 230–243 (2017)

Hosny, A., Parmar, C., Quackenbush, J., Schwartz, L.H., Aerts, H.J.: Artificial Intelligence in radiology. Nat. Rev. Cancer 18(8), 500–510 (2018)

Erickson, B.J., Korfiatis, P., Akkus, Z., Kline, T.L.: Machine learning for medical imaging. Radiographics 37(2), 505–515 (2017)

Shokri, R., Stronati, M., Song, C., Shmatikov, V.: Membership inference attacks against machine learning models. In: 2017 IEEE Symposium on Security and Privacy (SP), pp. 3–18. IEEE, May 2017

Biamonte, J., Wittek, P., Pancotti, N., Rebentrost, P., Wiebe, N., Lloyd, S.: Quantum machine learning. Nature 549(7671), 195–202 (2017)

Bacha, A., Benhra, J., Sabry, A.H.: A CNC machine fault diagnosis methodology based on Bayesian networks and data acquisition. Commun. Appl. Electron. 5, 41–48 (2016)

He, K., Yang, Z., Bai, Y., Long, J., Li, C.: Intelligent fault diagnosis of delta 3D printers using attitude sensors based on support vector machines. Sensors 18(4), 1298 (2018)

Shafique, M.T., Kamran, H., Arshad, H., Khattak, H.A.: Home energy monitoring system using wireless sensor network. In: 2018 14th International Conference on Emerging Technologies (ICET), pp. 1–6. IEEE, November 2018

Chen, T., Guestrin, C.: Xgboost: a scalable tree boosting system. In: Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, pp. 785–794, August 2016

Nguyen, H., Bui, X.-N., Bui, H.-B., Cuong, D.T.: Developing an XGBoost model to predict blast-induced peak particle velocity in an open-pit mine: a case study. Acta Geophys. 67(2), 477–490 (2019). https://doi.org/10.1007/s11600-019-00268-4

Zhang, D., Qian, L., Mao, B., Huang, C., Huang, B., Si, Y.: A data-driven design for fault detection of wind turbines using random forests and XGboost. IEEE Access 6, 21020–21031 (2018)

Dhaliwal, S.S., Nahid, A.A., Abbas, R.: Effective intrusion detection system using XGBoost. Information 9(7), 149 (2018)

Mitchell, R., Frank, E.: Accelerating the XGBoost algorithm using GPU computing. PeerJ Comput. Sci. 3, e127 (2017)

Yadav, S., Shukla, S.: Analysis of k-fold cross-validation over hold-out validation on colossal datasets for quality classification. In: 2016 IEEE 6th International Conference on Advanced Computing (IACC), pp. 78–83. IEEE, February 2016

Jung, Y.: Multiple predicting K-fold cross-validation for model selection. J. Nonparametric Stat. 30(1), 197–215 (2018)

Wong, T.T., Yeh, P.Y.: Reliable accuracy estimates from k-fold cross validation. IEEE Trans. Knowl. Data Eng. 32(8), 1586–1594 (2019)

Ruuska, S., Hämäläinen, W., Kajava, S., Mughal, M., Matilainen, P., Mononen, J.: Evaluation of the confusion matrix method in the validation of an automated system for measuring feeding behaviour of cattle. Behav. Proc. 148, 56–62 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Özsoy, K., Halis, H.D. (2021). Fault Analysis in the Field of Fused Deposition Modelling (FDM) 3D Printing Using Artificial Intelligence. In: Hemanth, J., Yigit, T., Patrut, B., Angelopoulou, A. (eds) Trends in Data Engineering Methods for Intelligent Systems. ICAIAME 2020. Lecture Notes on Data Engineering and Communications Technologies, vol 76. Springer, Cham. https://doi.org/10.1007/978-3-030-79357-9_54

Download citation

DOI: https://doi.org/10.1007/978-3-030-79357-9_54

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-79356-2

Online ISBN: 978-3-030-79357-9

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)